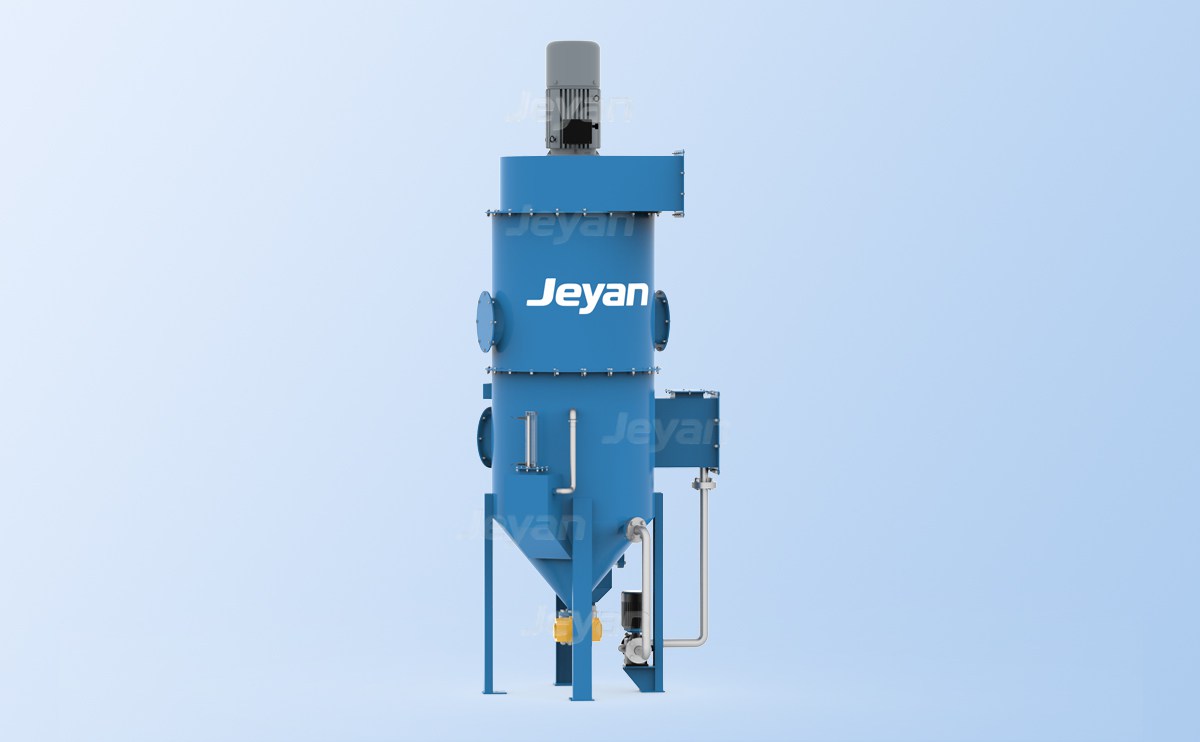

MDC-V Wet Collector

The MDC-V-series e wet dust collector is designed based on the principles of cyclone wet dustremoval and high-efficiency Venturi. It is used to process high concentration dust, make dustygases and liquids in close contact, and use gravity, inertia collision, interception, diffusion andother effects to capture particles or increase particle size. It can effectively remove liquid orsolid particles with a diameter of 0,1-20 μ m, as well as gaseous pollutants.

Viscous dust

Steam and oil fog

Flammable and explosive dust

Rubber / Leather / Plastic powder

Fiber / Fluff / Fabric dust

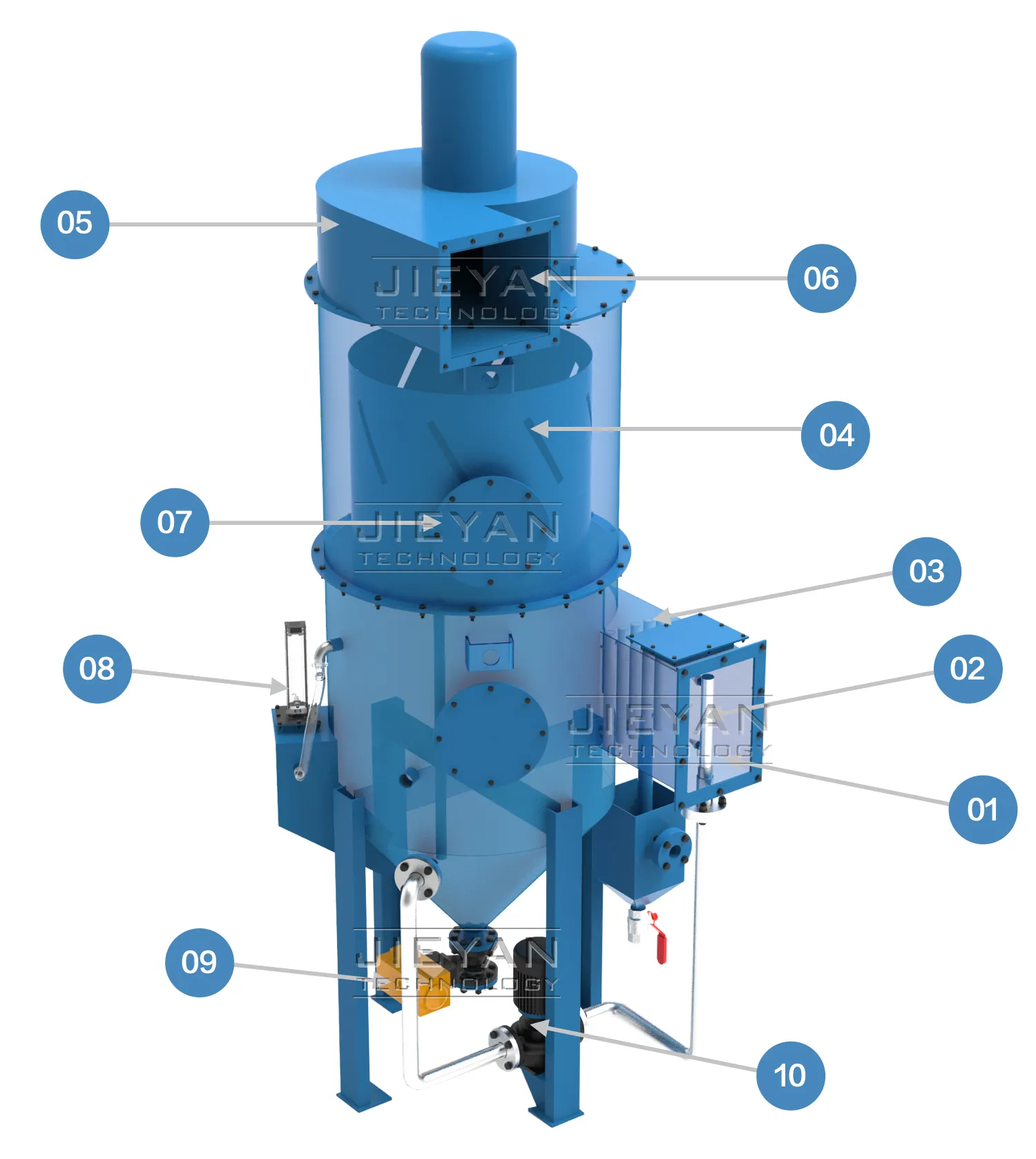

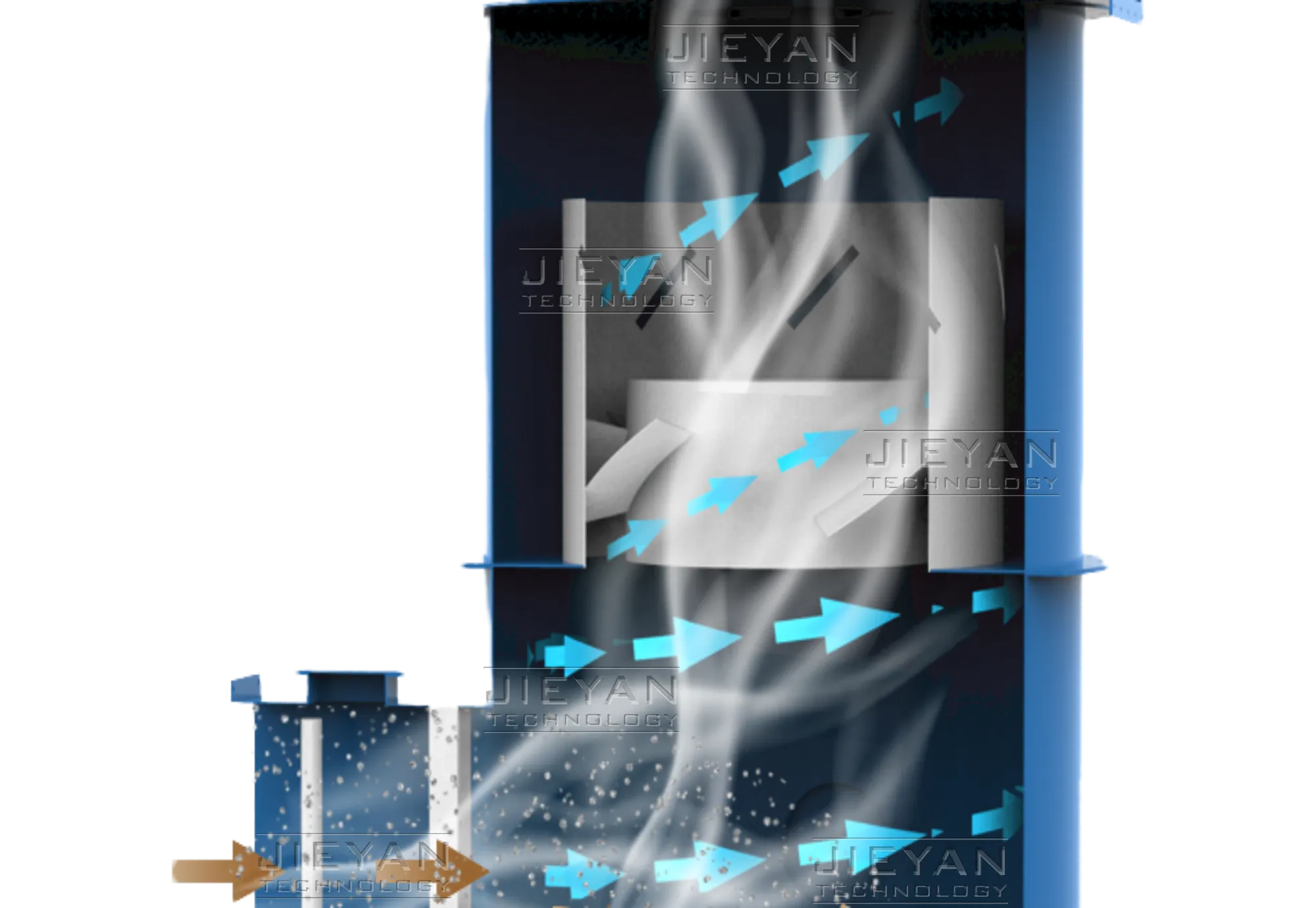

Structure and Principle

The MDC-V vertical dust collector adopts high-efficiency cyclone separation and two-stage cyclone dehazing technology to achieve deep gas-liquid separation. The top mounted structure of the fan is highly compact, significantly saving space. The integrated sewage sedimentation circulation system and intelligent sewage discharge function, combined with large aperture non clogging spray and reliable liquid level monitoring, ensure efficient dust removal, low maintenance, and stable operation, making it an ideal choice for high space utilization requirements.

① Air Inlet

② Spray System

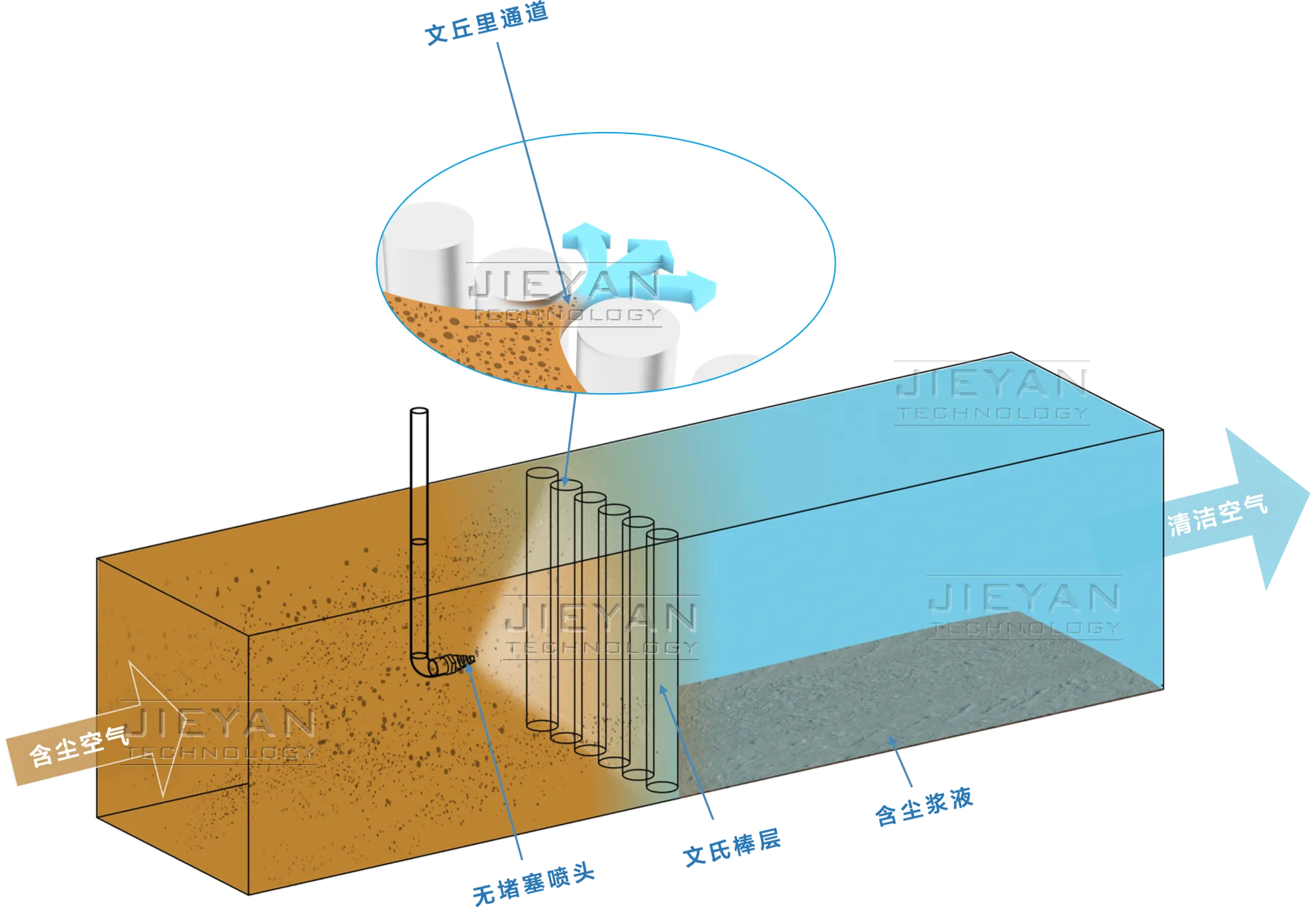

③ Venturi Rod Layer

④ Mist Eliminator

⑤ Fan

⑥ Air Outlet

⑦ Inspection Door

⑧ Level Gauge

⑨ Blowdown Valve

⑩ Pump

Multiple structures, more choices

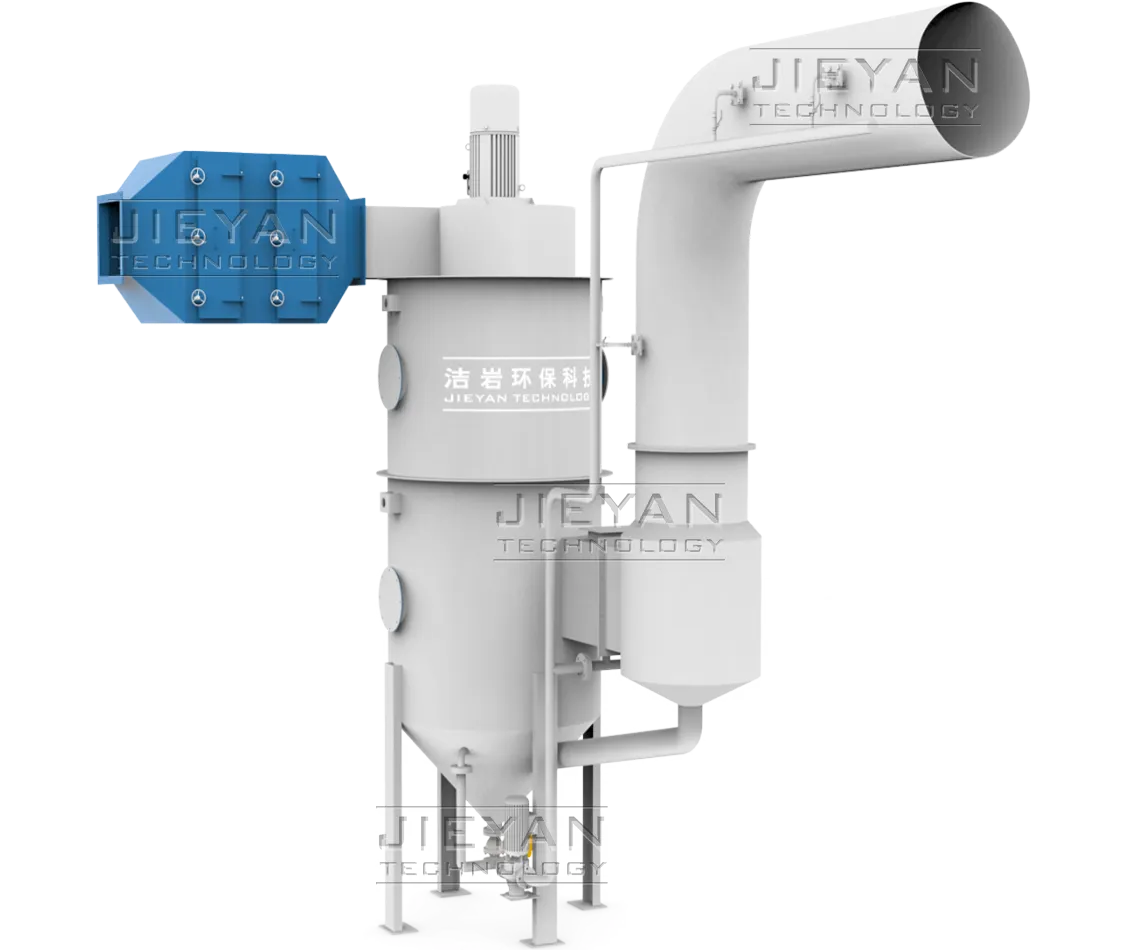

MDC-V Wet Collector (Automatic Slag-Flushing Type)

MDC-V Series (Automatic Slag-Flushing Type) can discharge the settled sludge from the bottom outlet of the settling tank hopper. The sludge is transported through a pipeline system to the final disposal point. Both continuous and intermittent slag flushing modes are available. This slag removal method is suitable for material conveying, crushing dust collection, screening, and transfer points in the chemical, mining, and quarrying industries.

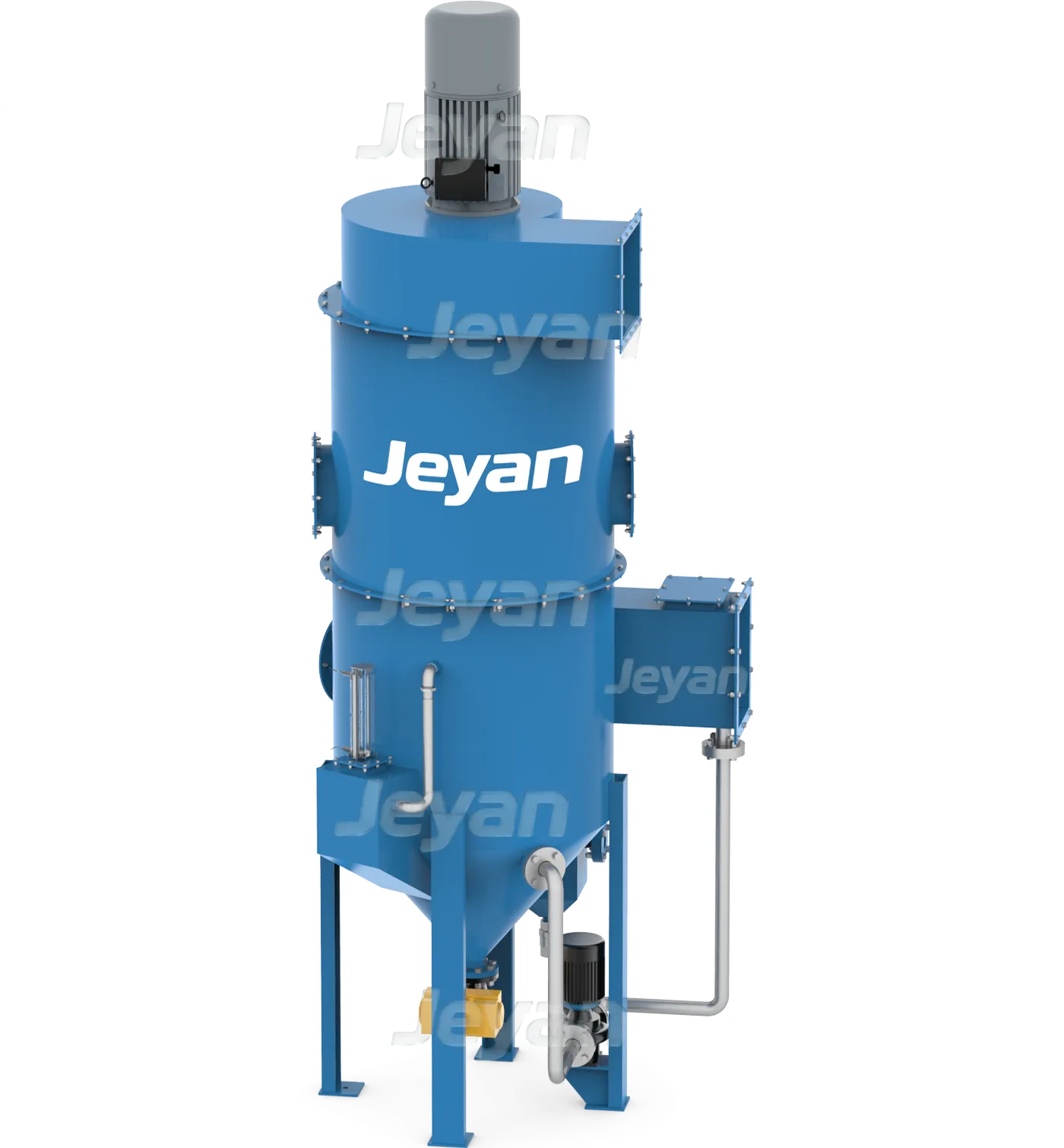

MDC-V Wet Collector(Manual Sludge Discharge Type)

The MDC-V Manual De-sludging Series features a compact design with reduced height and lower capital investment. Designed for manual sludge removal, this configuration is ideal for light dust loading applications including dust collection from polishing, grinding, metalworking, packaging, sorting, weighing, and chemical processing exhausts.

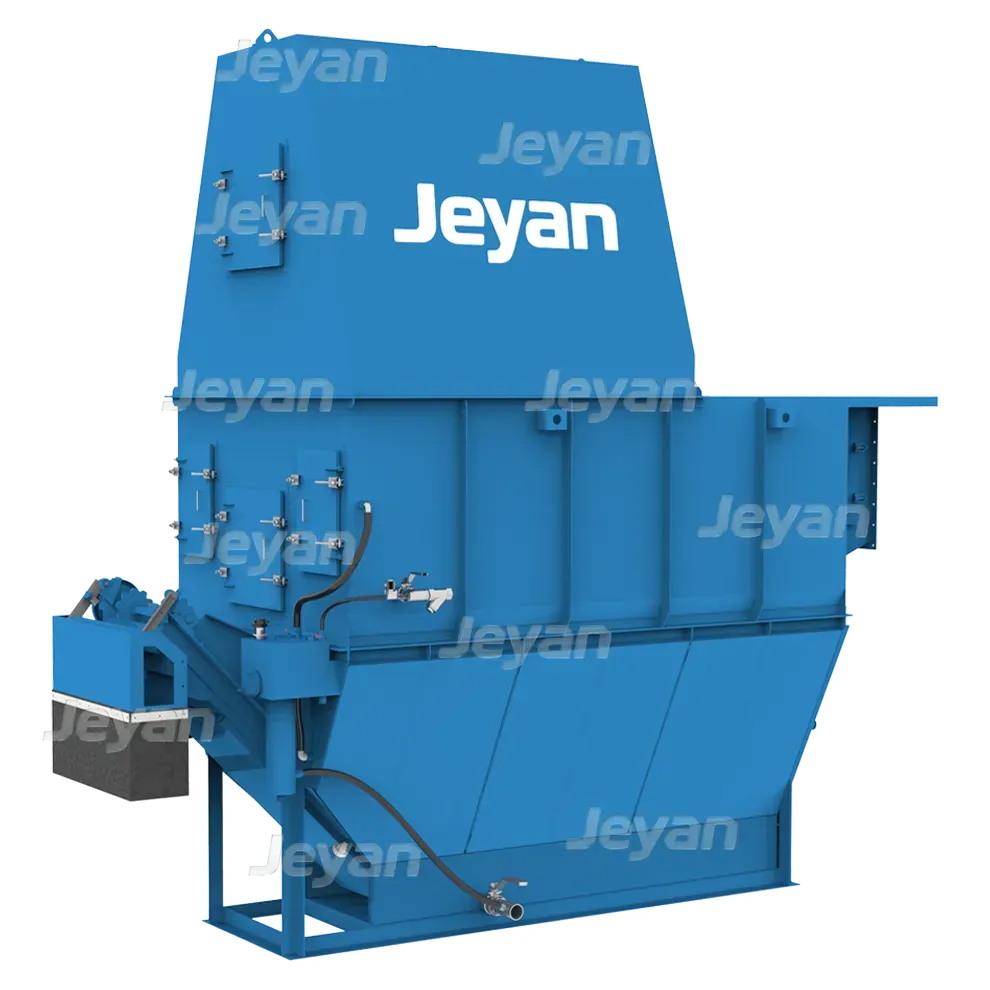

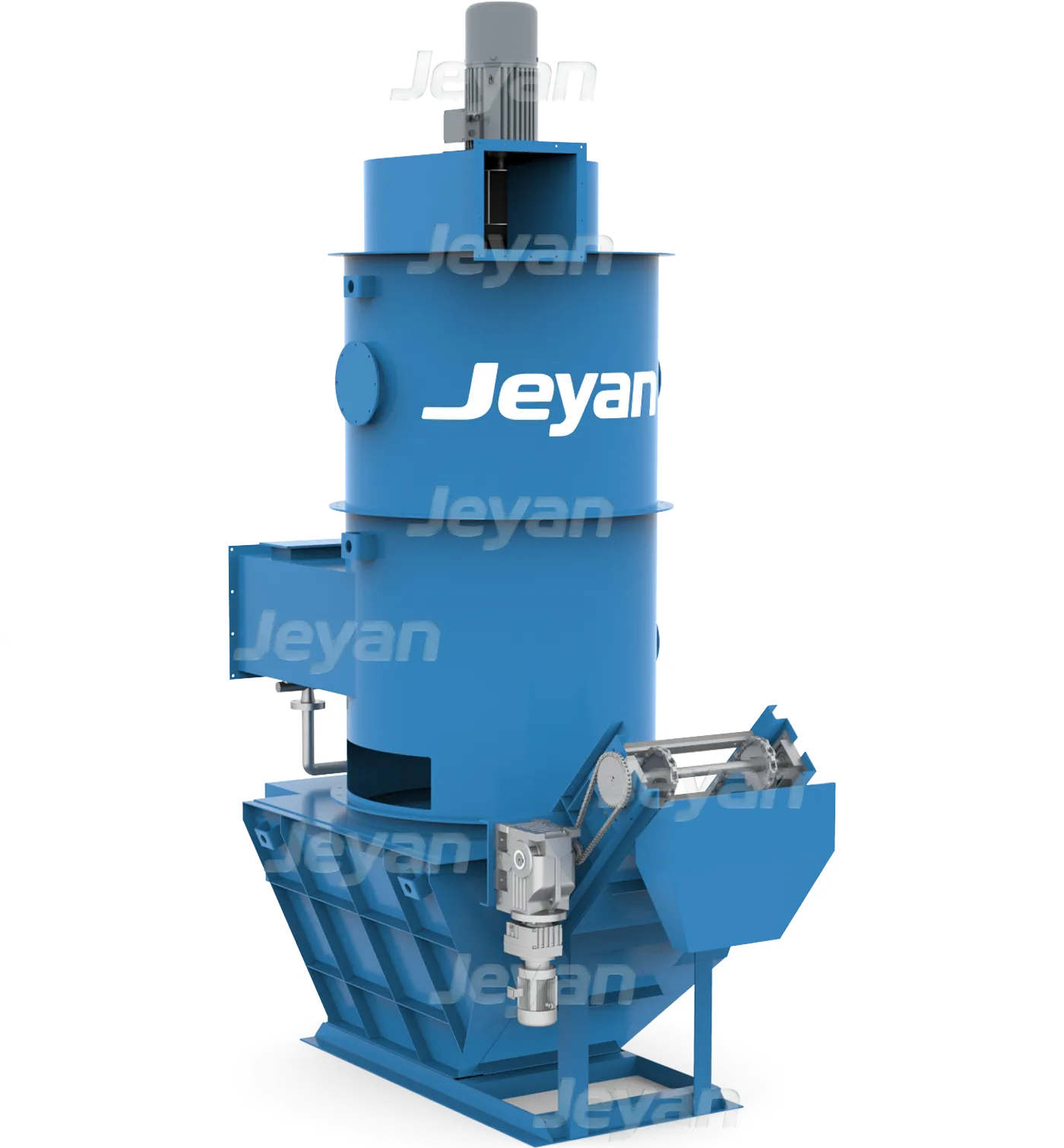

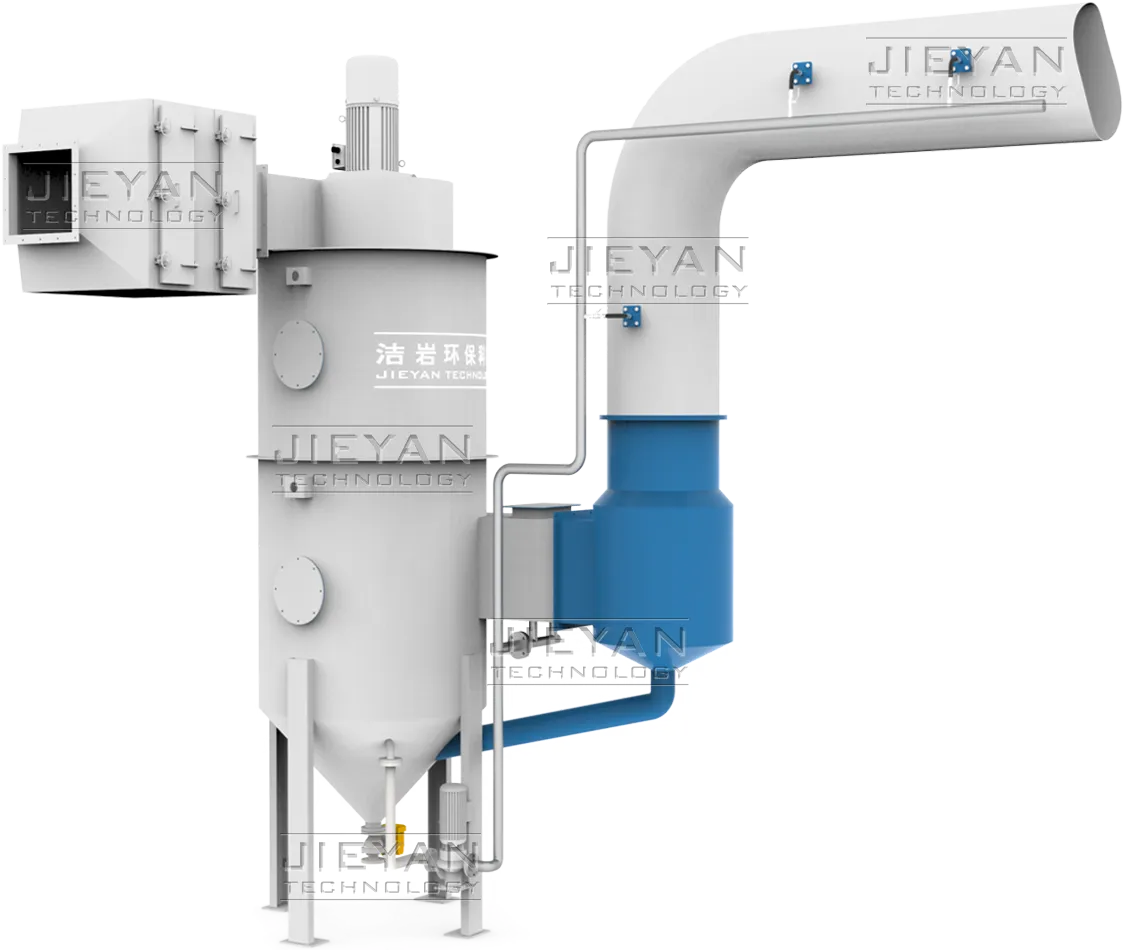

MDC-V Wet Collector(Automatic Scraper Type)

The MDC-V Auto-Scraping Series minimizes manual sludge handling. It is ideal for handling moderate to heavy dust-loading gas streams requiring 24/7 continuous operation, or where manual sludge removal proves impractical or uneconomical. This system is widely employed in foundry exhaust, green sand handling, abrasive blasting, polishing and grinding, material conveying, drying operations, and various industrial processing applications.

Technical Features

Venturi Rod Efficiency

The MDC series integrates an innovative Venturi rod layer that splits incoming air into multiple smaller channels. This design maintains steady flow with minimal pressure drop while intensifying the Venturi effect for superior dust capture - achieving the perfect balance between maximum efficiency and minimal resistance.

Two-Stage Moisture Separation

Our advanced dual-stage design first uses centrifugal force from tangential airflow to separate heavier droplets. The second stage features a unique twin-cyclonic separator that isolates moisture from rising air, preventing re-entrainment and ensuring peak dehumidification performance.

Integrated Top Fan

Units below 40,000 airflow feature a roof-mounted fan that eliminates ductwork and saves space. With over 3500Pa pressure capacity, it delivers robust suction power for most applications while simplifying installation.

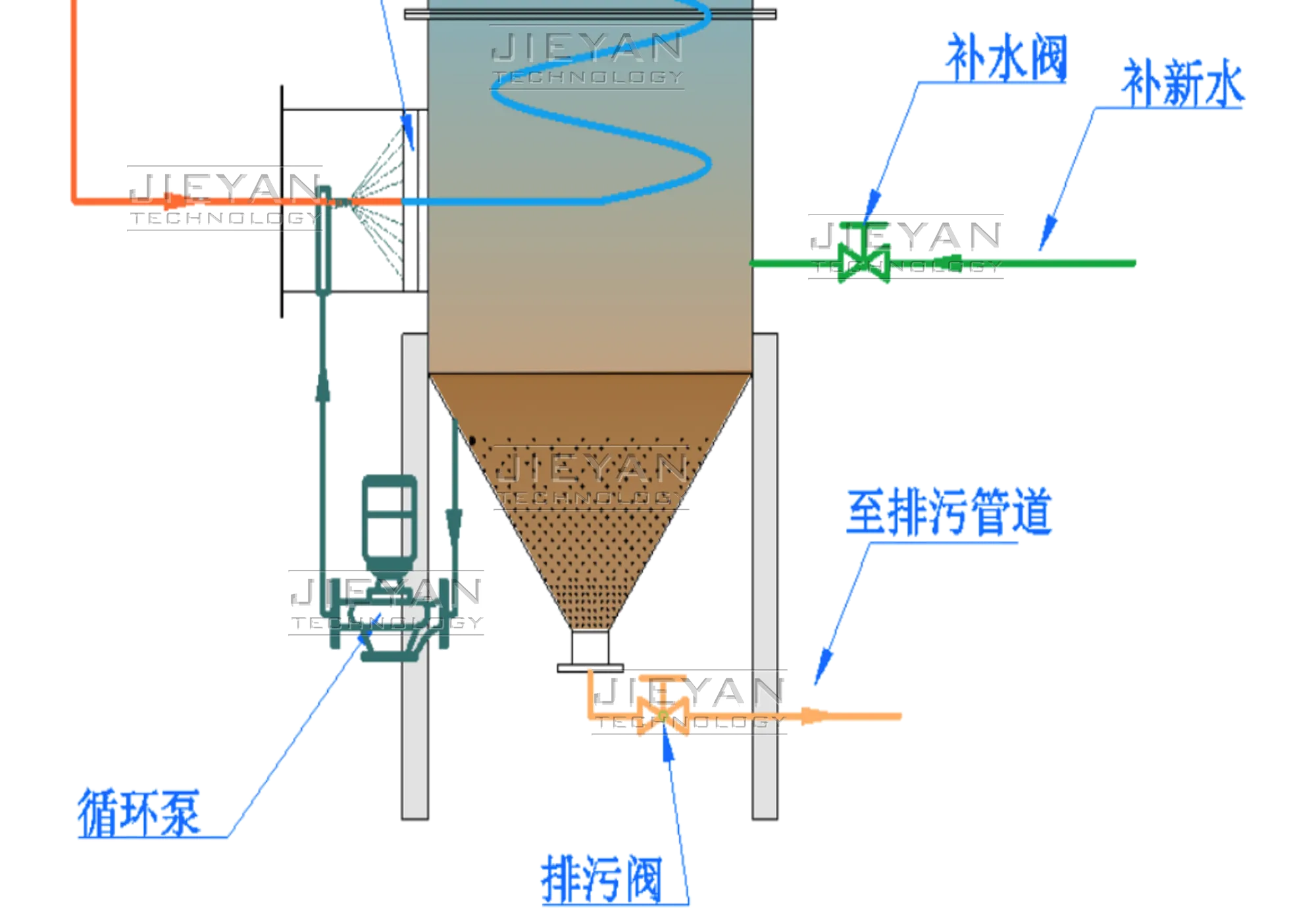

Closed-Loop Water System

The MDC-V series recycles water continuously. Settled dust discharges from the cone bottom while clarified water recirculates through 304 stainless steel pumps. This zero-discharge system uses specialized pumps resistant to abrasive particles for reliable operation.

Automated Drainage

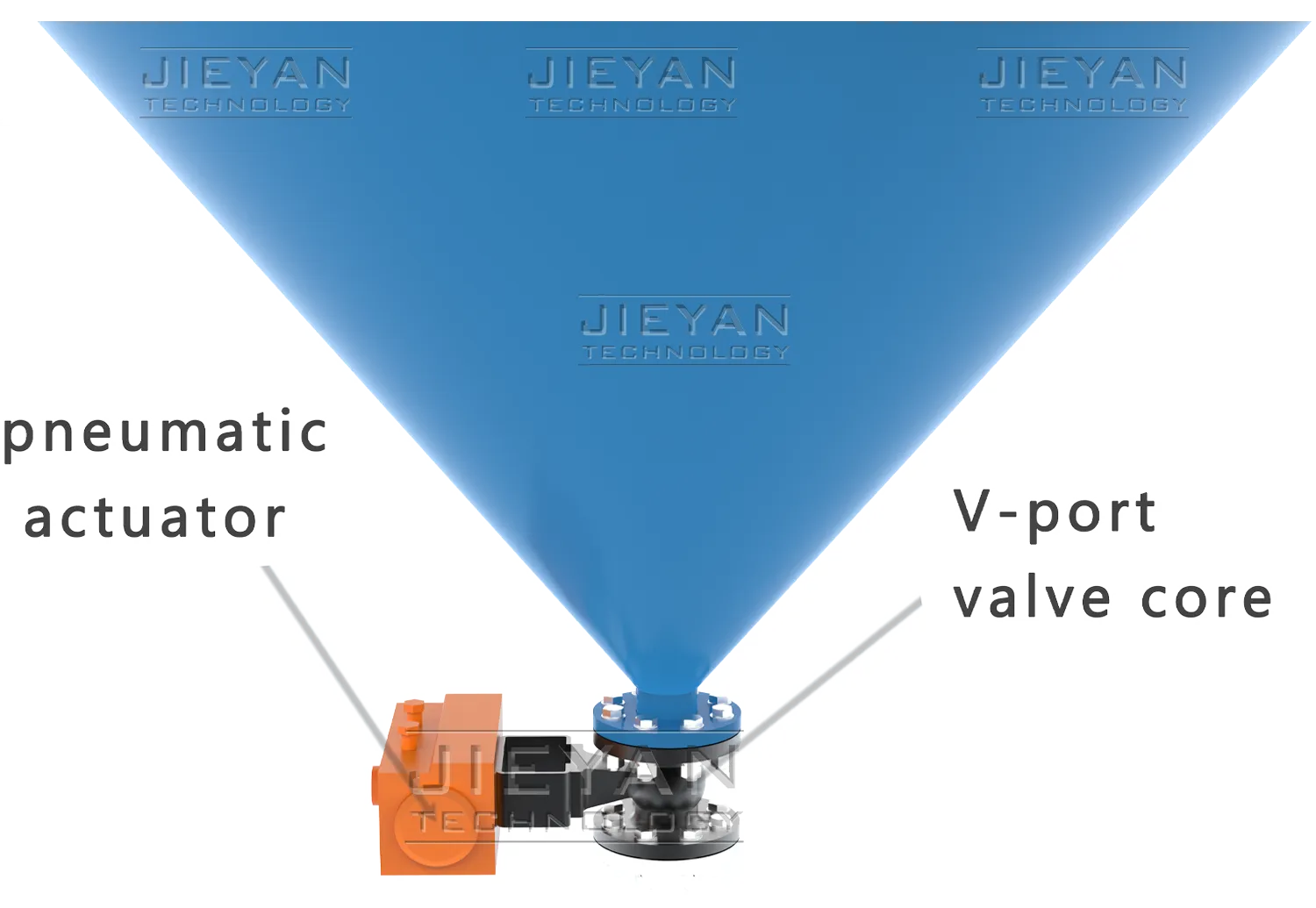

Featuring a V-port, chrome-plated 304 stainless valve that resists jamming and wear. The pneumatic actuator enables rapid cycling with powerful flushing action, while adjustable intervals minimize water usage and reduce treatment load.

Automatic Water Supply*

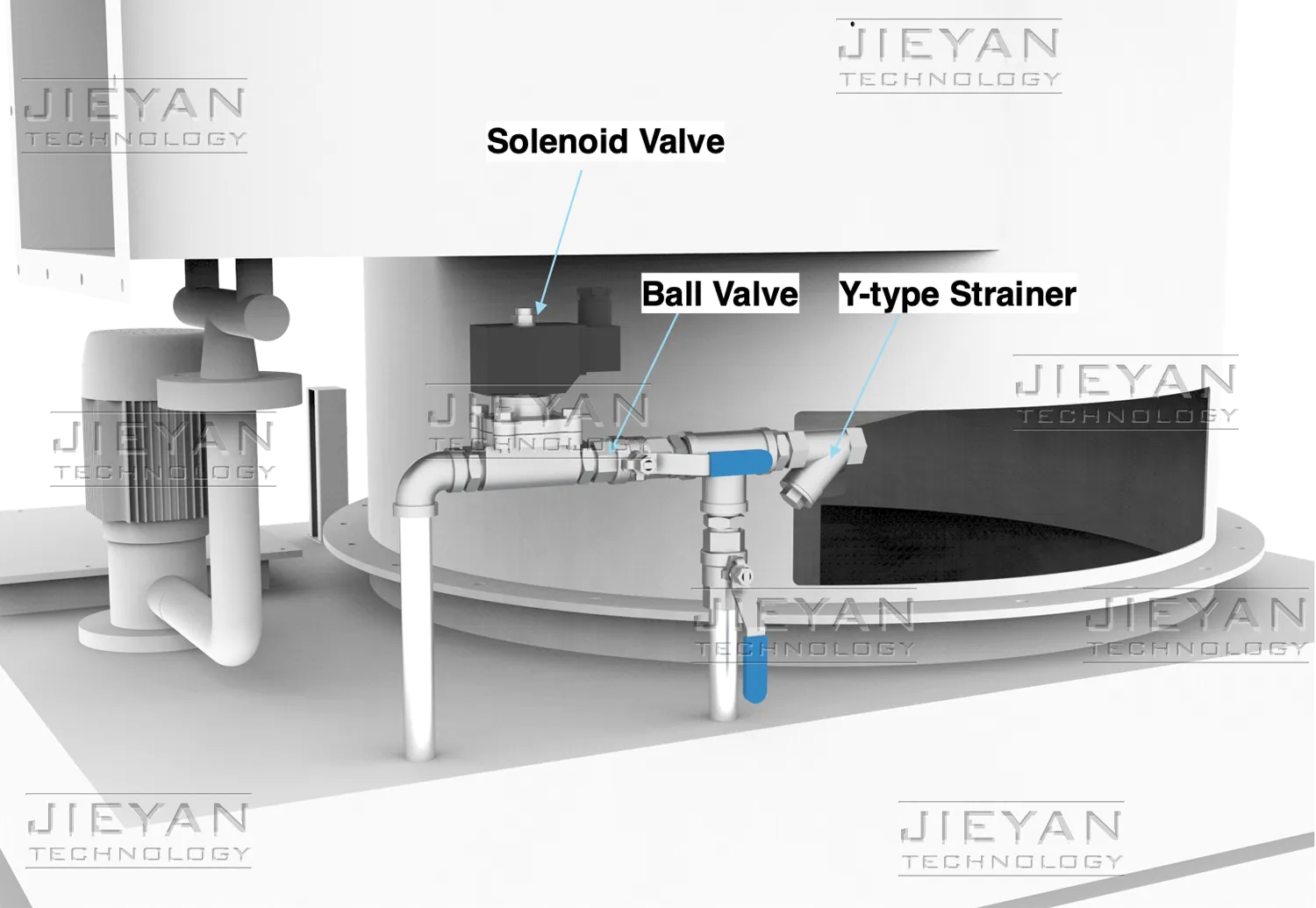

Operates in both manual and automatic modes with integrated filtration to prevent clogging. Precision solenoid valves maintain consistent water levels for uninterrupted system performance.

Reliable Level Sensing

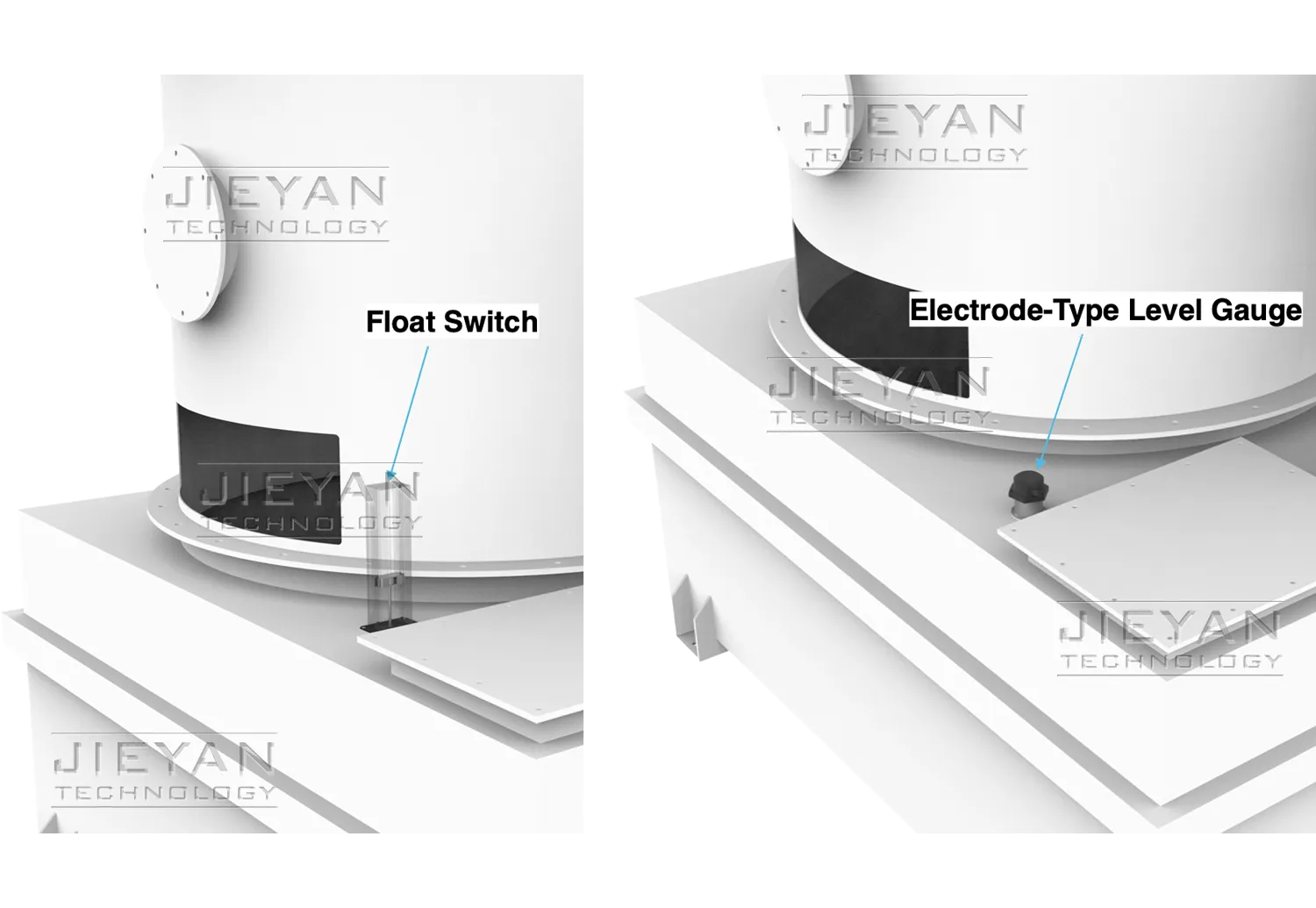

Choose between electrode or float sensors for automatic refill and dry-run protection. The contact-free float design remains unaffected by solids or pH variations, ensuring long-term accuracy and durability.

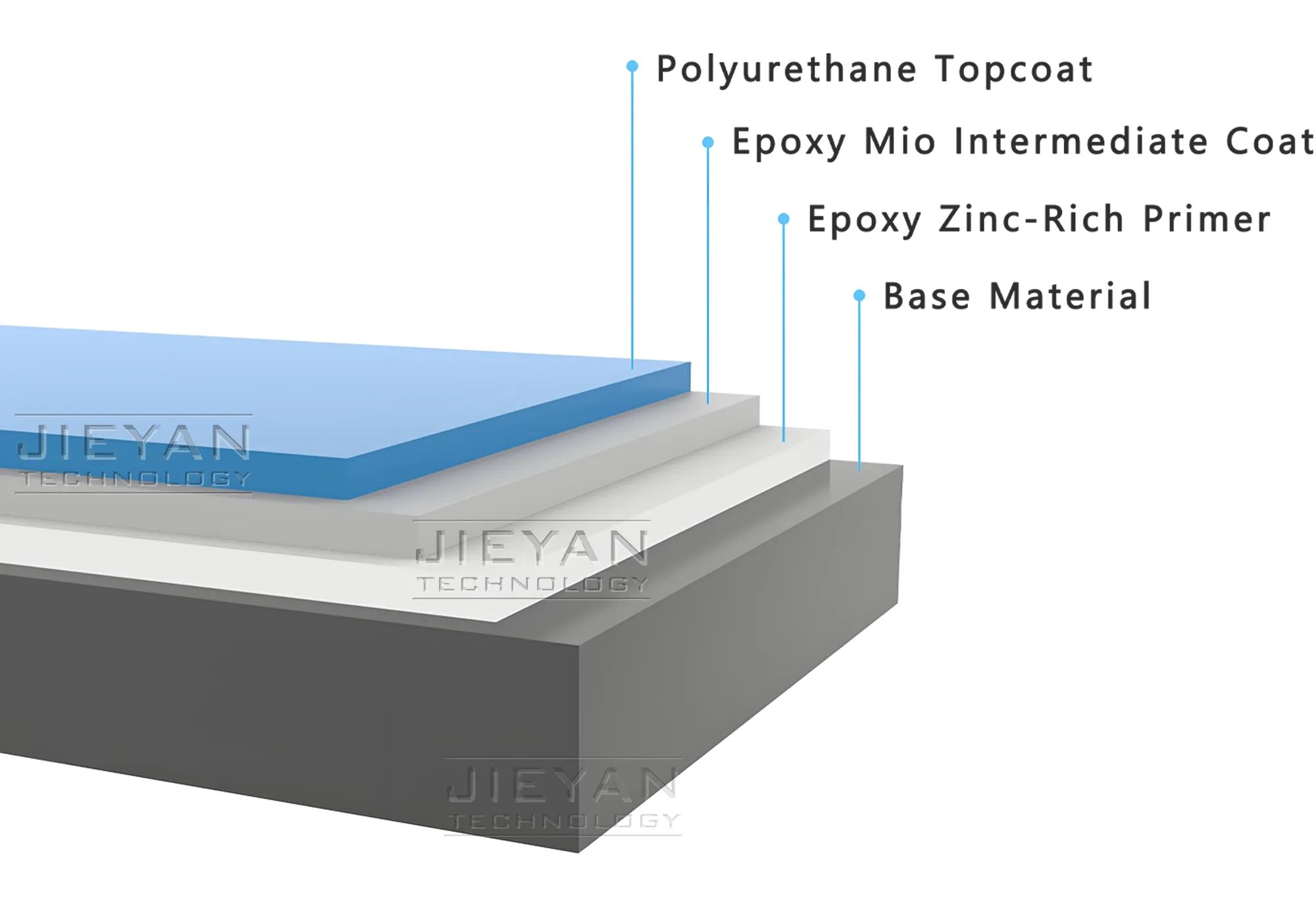

Advanced Anti-Corrosion Protection

Each unit is shot-blasted to SA2.5 standard before receiving a triple-layer coating system: zinc-rich epoxy primer, micaceous iron oxide intermediate, and polyurethane topcoat. With ≥200μm total thickness, it withstands the harshest conditions.

Smart PLC Control

Complete with PLC and touchscreen for easy parameter adjustment. Ethernet connectivity enables seamless integration with existing control systems for remote monitoring and intelligent management.

Optional Accessories

High Efficiency Air Filter (HEPA)

Dust Pretreatment Device

Related Cases

Related products

Contact Us

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219

Submit Successfully!

We have received your message and will contact you soon.