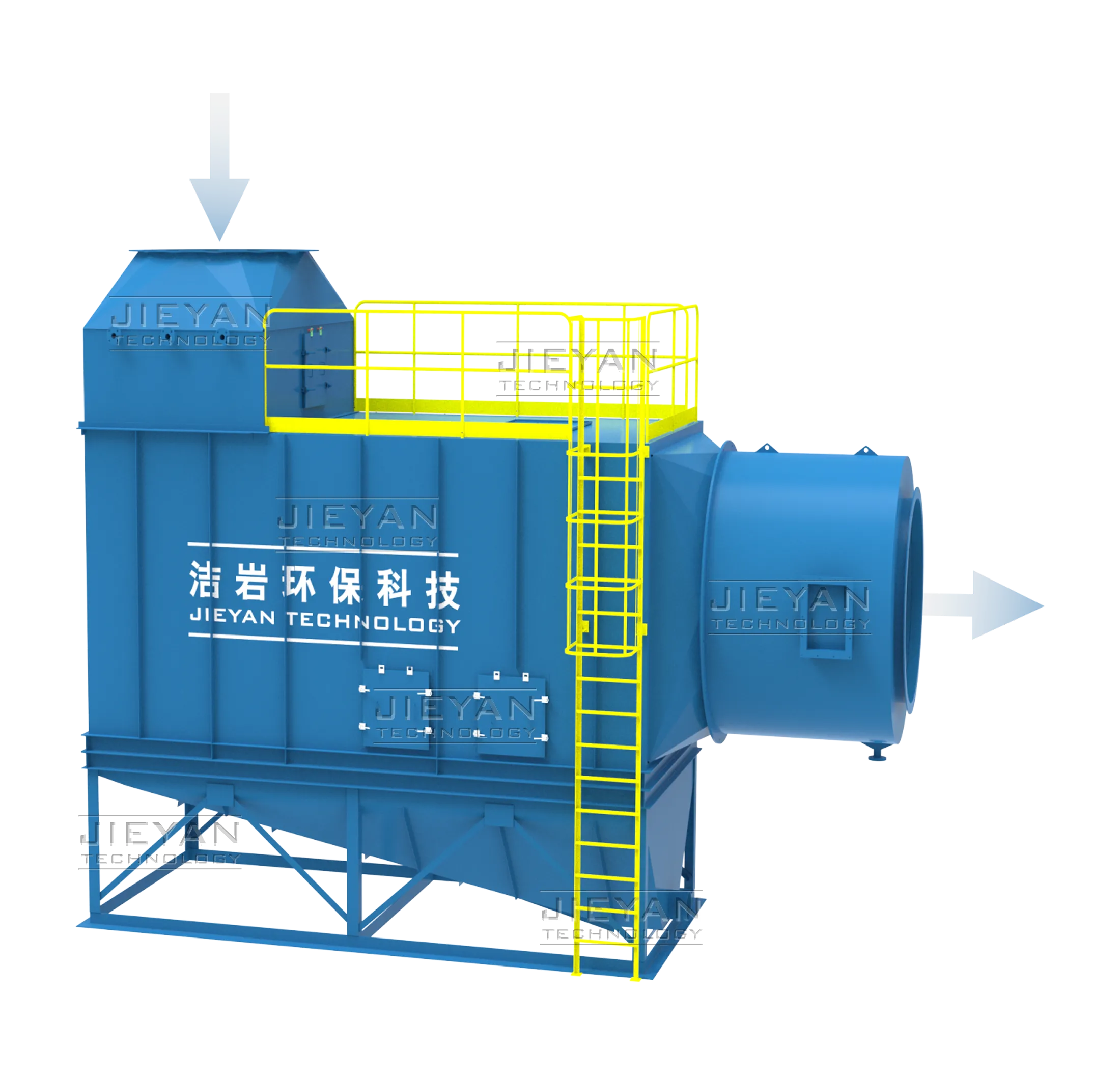

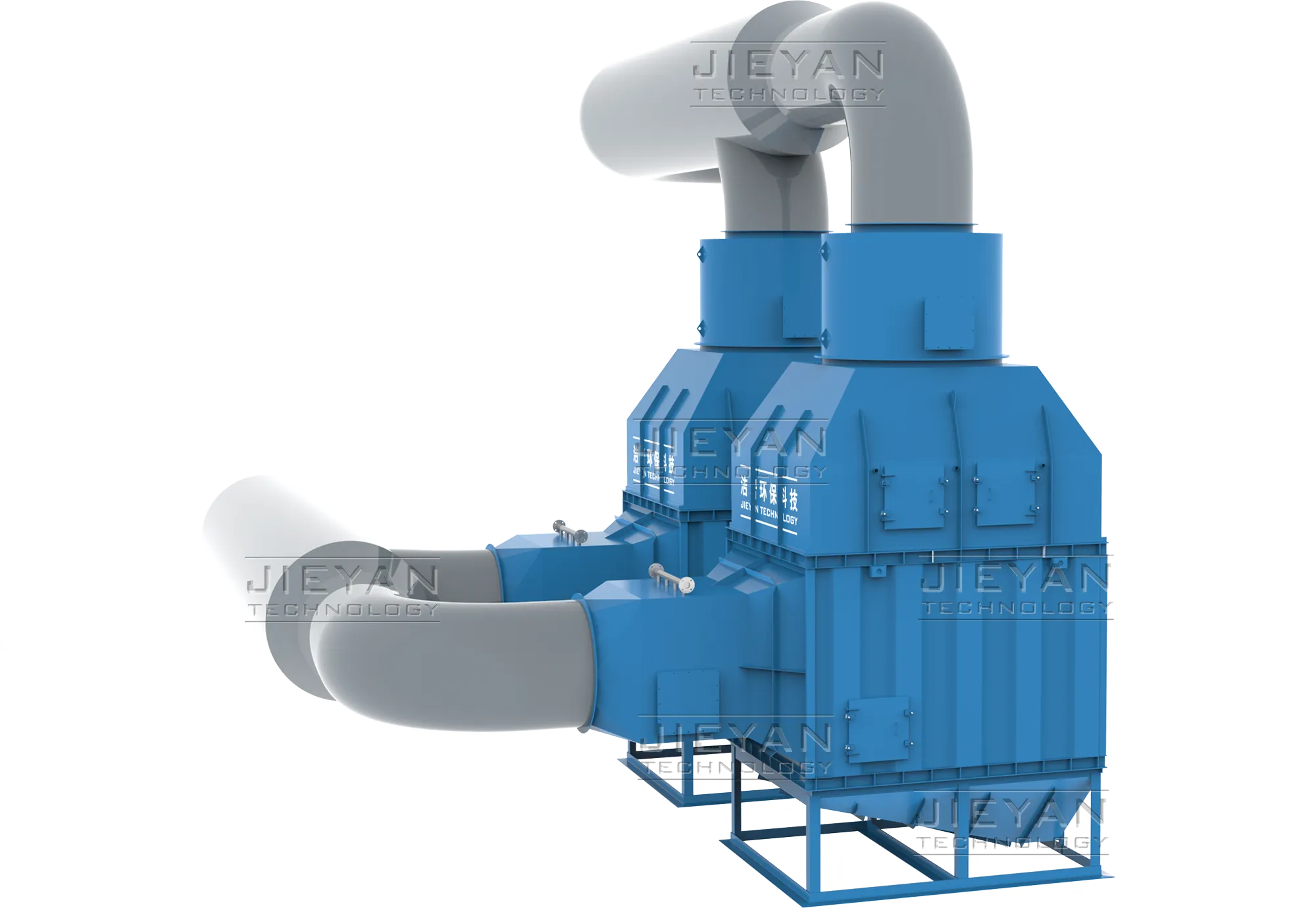

MDC-L Wet Collector

The MDC series L-type large-scale dust collector is designed specifically for processing extremely high air volume gases, with a maximum processing capacity of 300000 cubic meters per hour per unit, suitable for large-scale industrial production scenarios. The device adopts a three-level high-efficiency dehazing structure: the first level folded plate dehazing achieves preliminary separation and uniform distribution of airflow; The secondary baffle intercepts the vast majority of dust and mist droplets; The three-stage cyclone deep defogging utilizes strong centrifugal force to achieve final deep purification, ensuring emissions meet standards. The L-shaped dust collector has a flexible air inlet and outlet layout, and can adopt a side inlet and side outlet form according to site conditions, simplifying pipeline layout and reducing investment costs. Equipped with large aperture non clogging spray nozzles to ensure long-term stable operation. Simultaneously supporting multiple parallel operations and providing modular expansion capabilities to meet the growing demand for air volume processing, it is an ideal and efficient dust removal solution for large-scale engineering projects.

Sintering mixer dust removal

Steel slag treatment dedusting

Lime slaker dust collection

Shuttle belt conveyor dedusting

Pelletizer dust removal

Dryer dedusting

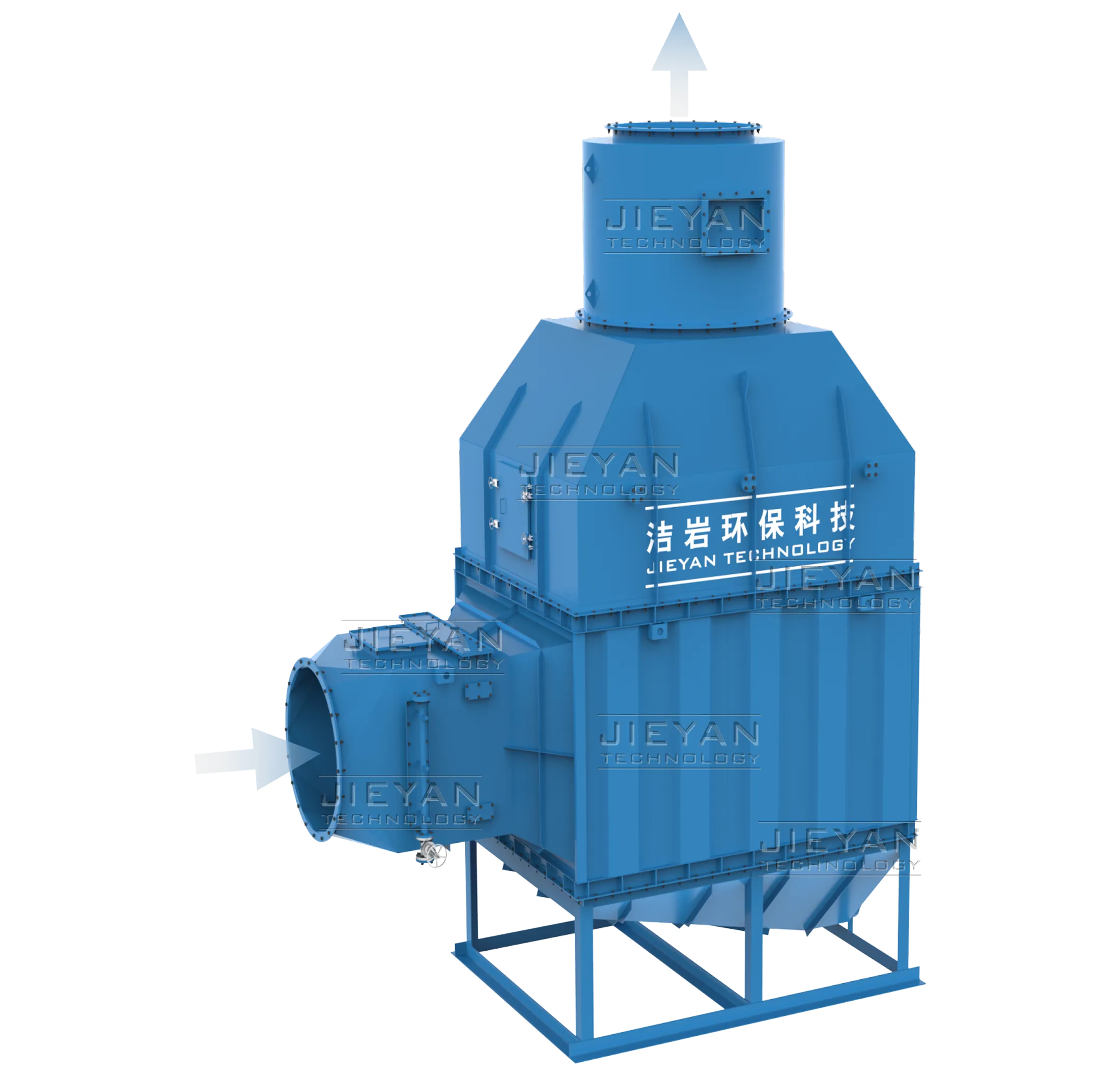

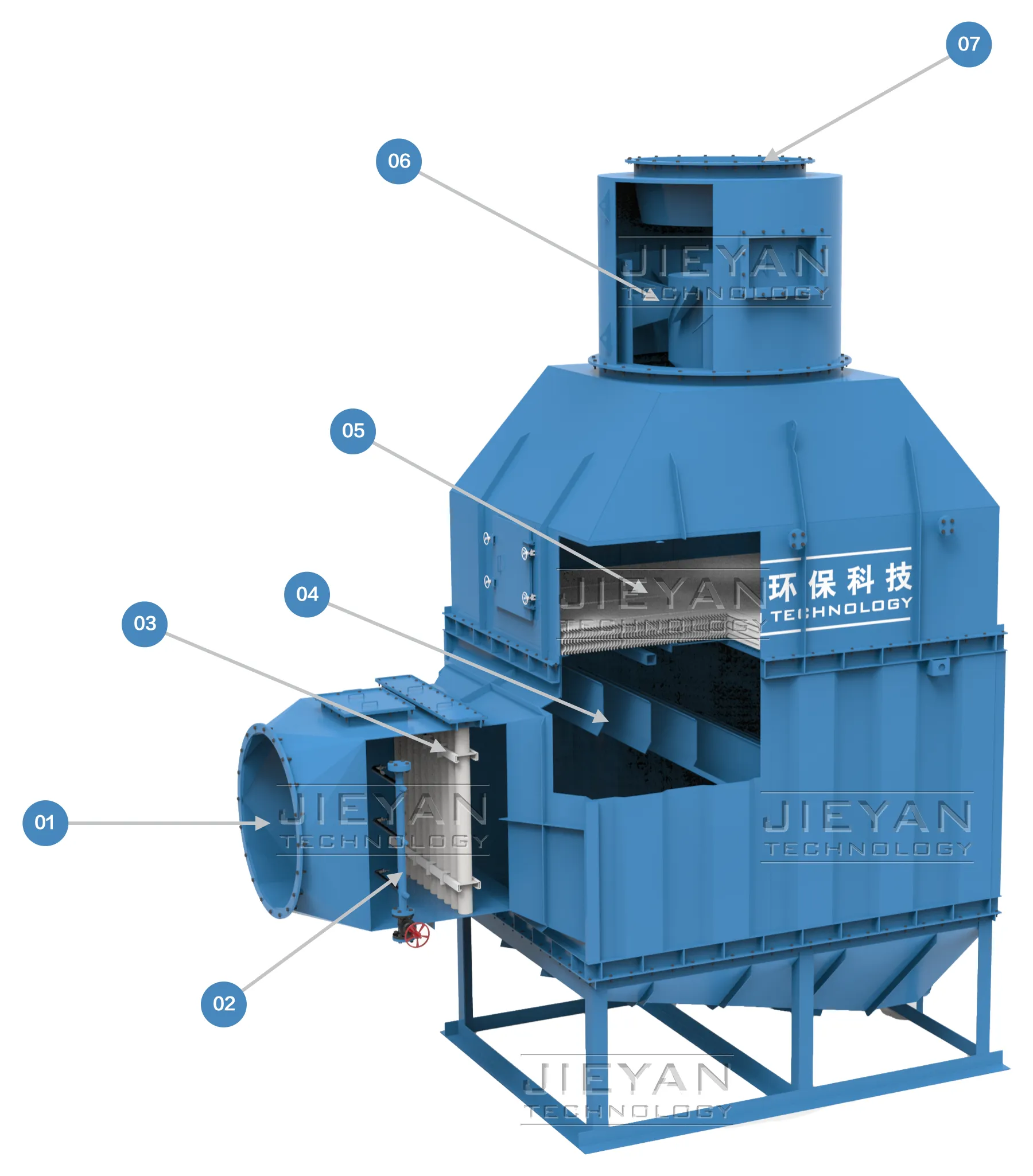

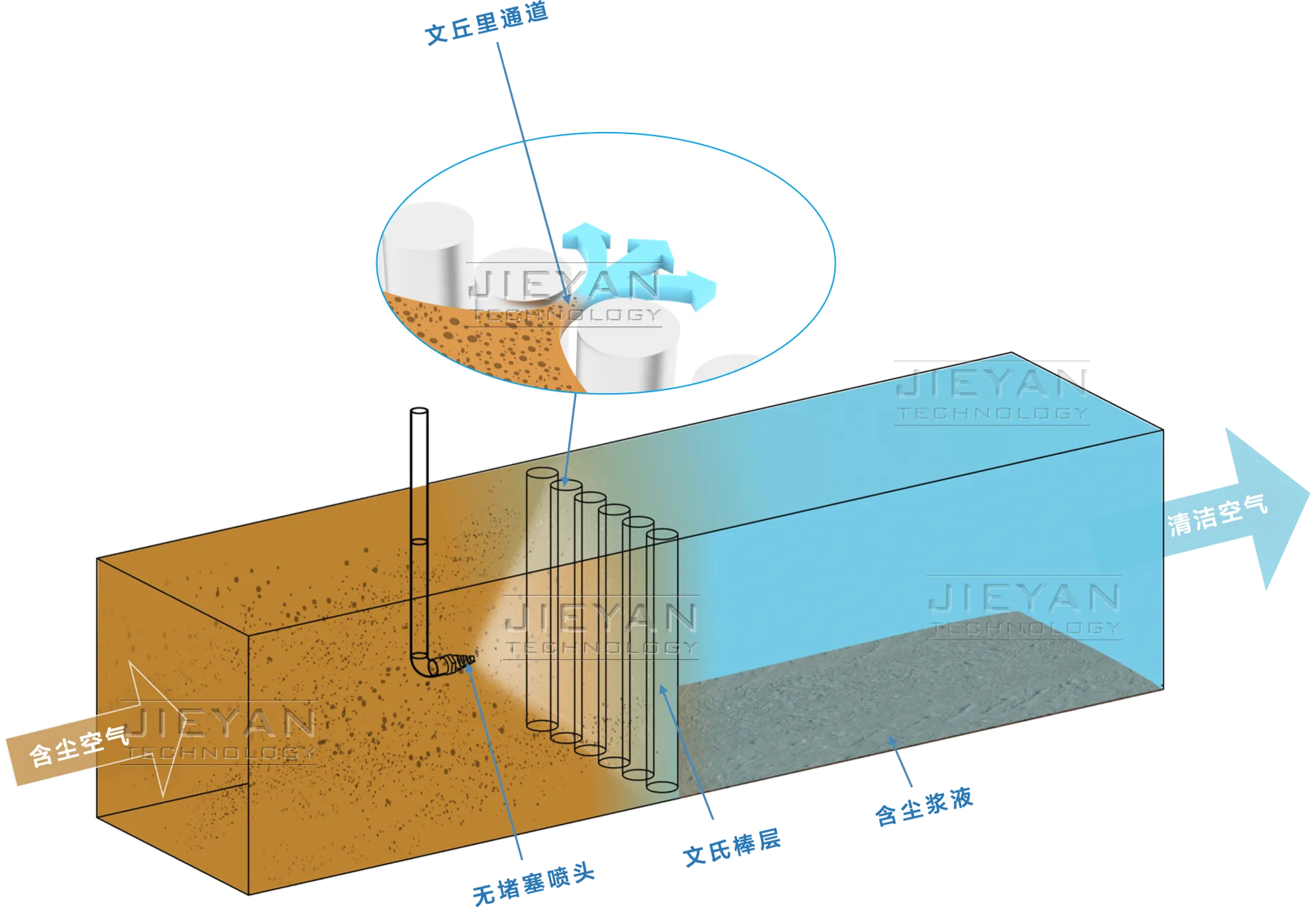

Structure and Principle

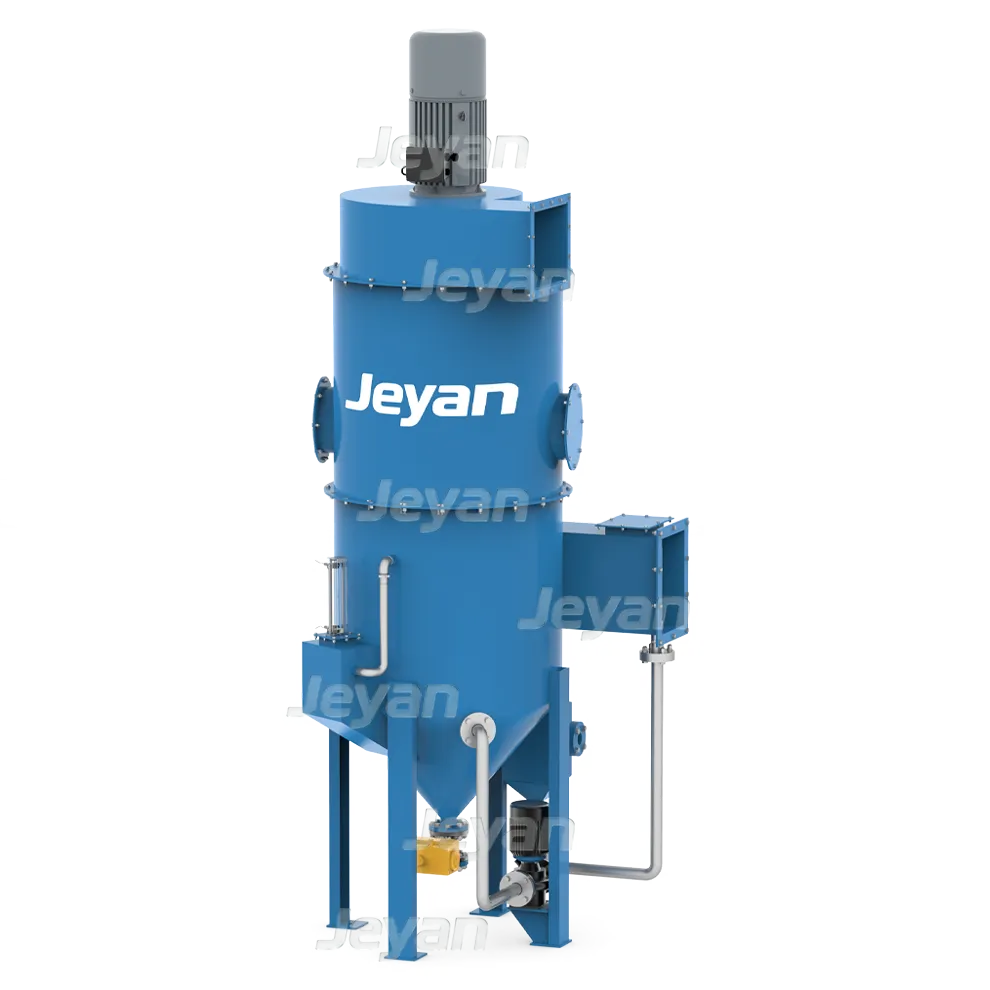

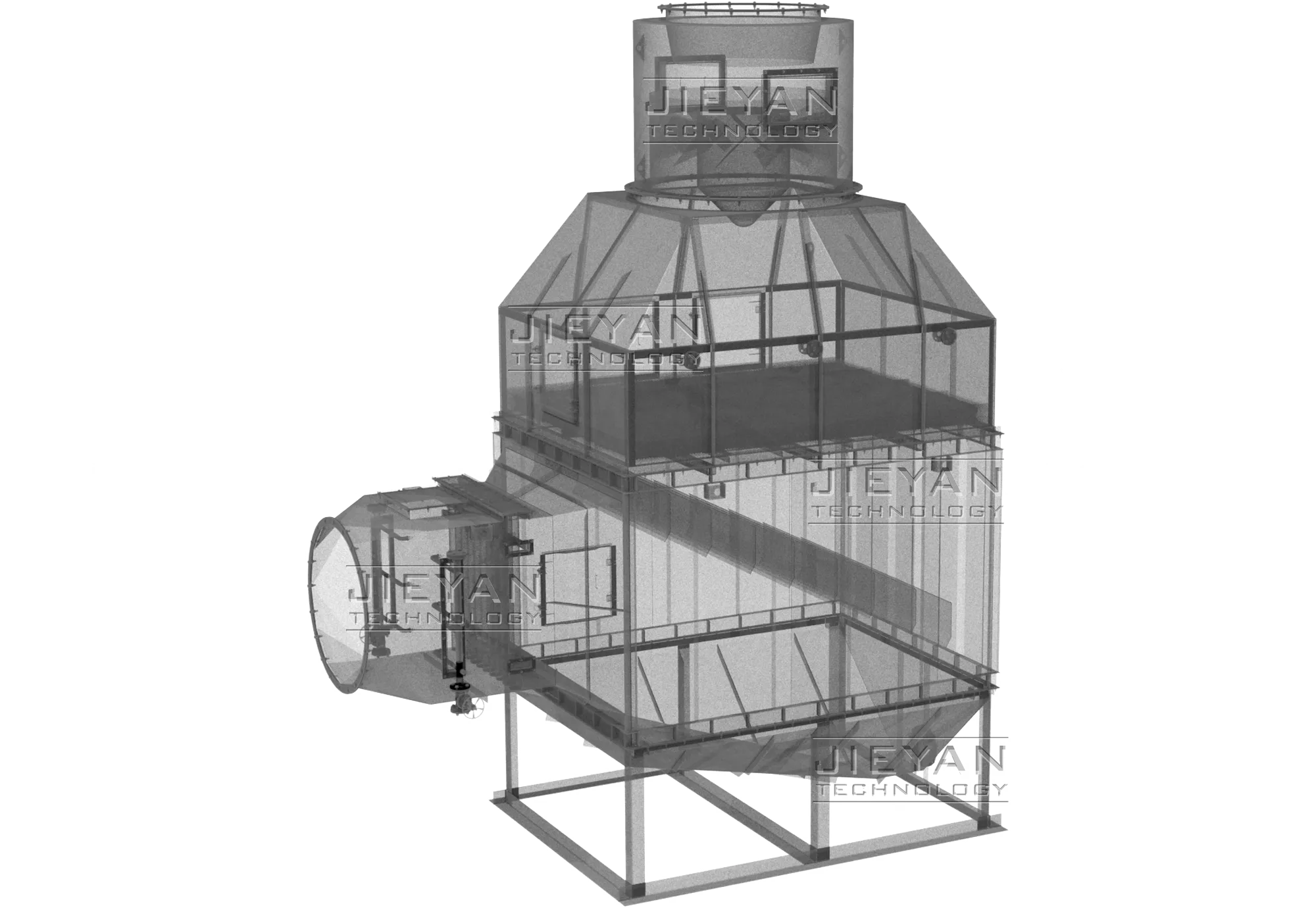

The MDC series wet Venturi dust collector breaks through traditional design and abandons the rapid contraction throat structure that can easily cause a significant increase in resistance. Add a Venturi rod layer internally to evenly divide the channel into multiple small Venturi channels. When the dusty gas enters at a constant speed, there is no significant pressure loss. After entering the microchannel, it is guided by the Wen's rod to form a "contraction throat expansion" flow field. The expansion section vigorously mixes with the sprayed water mist, and the water mist wraps around the dust and aggregates it. The dust droplets and washed exhaust gas enter the downstream centrifugal separation structure tangentially; After leaving the throat, the airflow enters the dust collector chamber, and the dusty airflow is introduced from the lower part of the cylinder. Due to the special airflow path, a strong water vortex is formed, and the dusty droplets are completely captured by the synergistic effect of gravity settling, centrifugal separation, and baffle interception, achieving the separation of dust and gas; The clean gas purified by dust removal is discharged from the top outlet of the dust collector into the system; The washing water separates pollutants through sedimentation in the collection area, and the bottom sediment can be collected and cleaned in various ways.

① Air Inlet

② Spray System

③ Venturi Rod Layer

④ Primary Mist Eliminator Unit

⑤ Secondary Mist Eliminator Unit

⑥ Tertiary Mist Eliminator Unit

⑦ Air Outlet

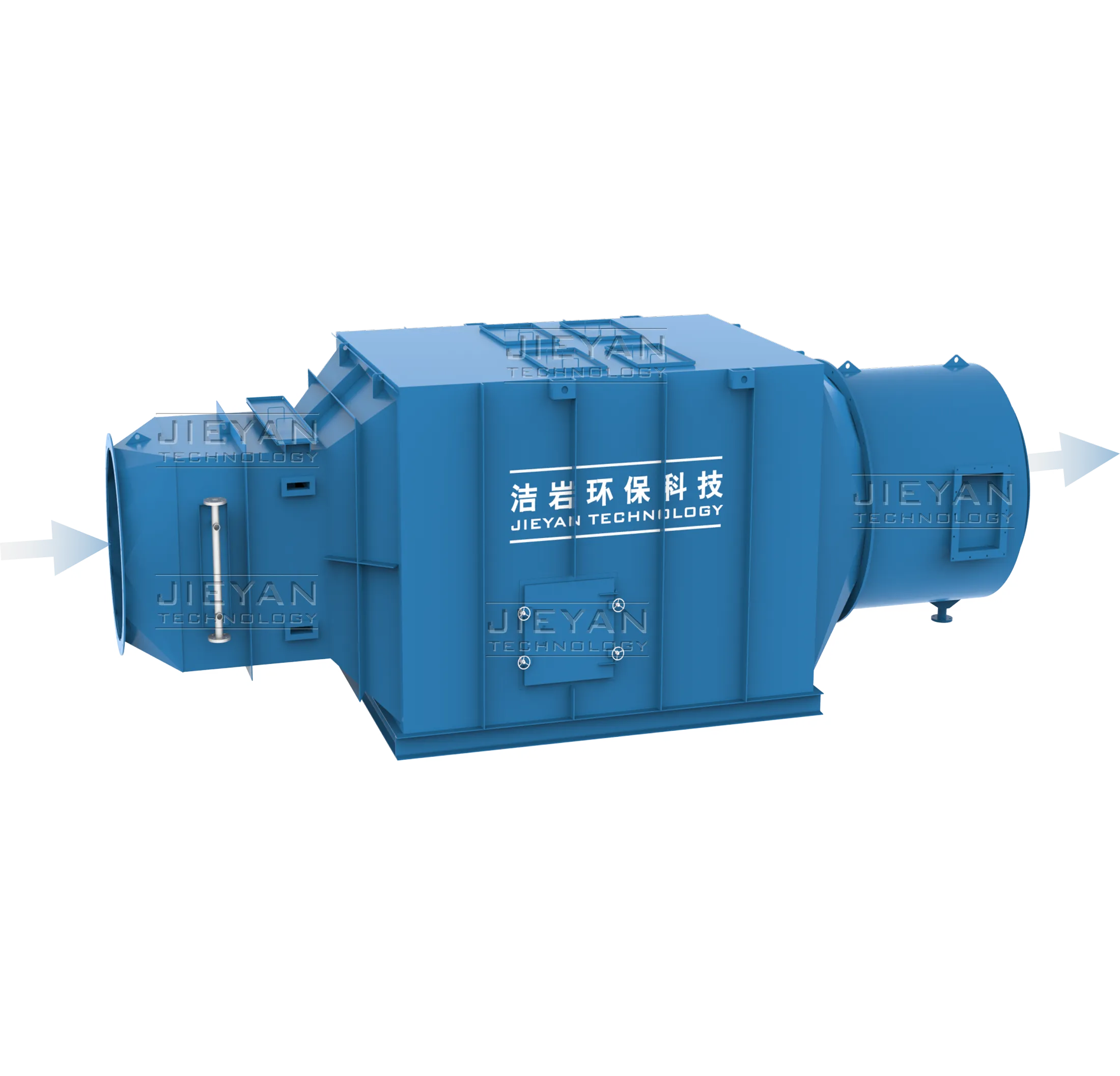

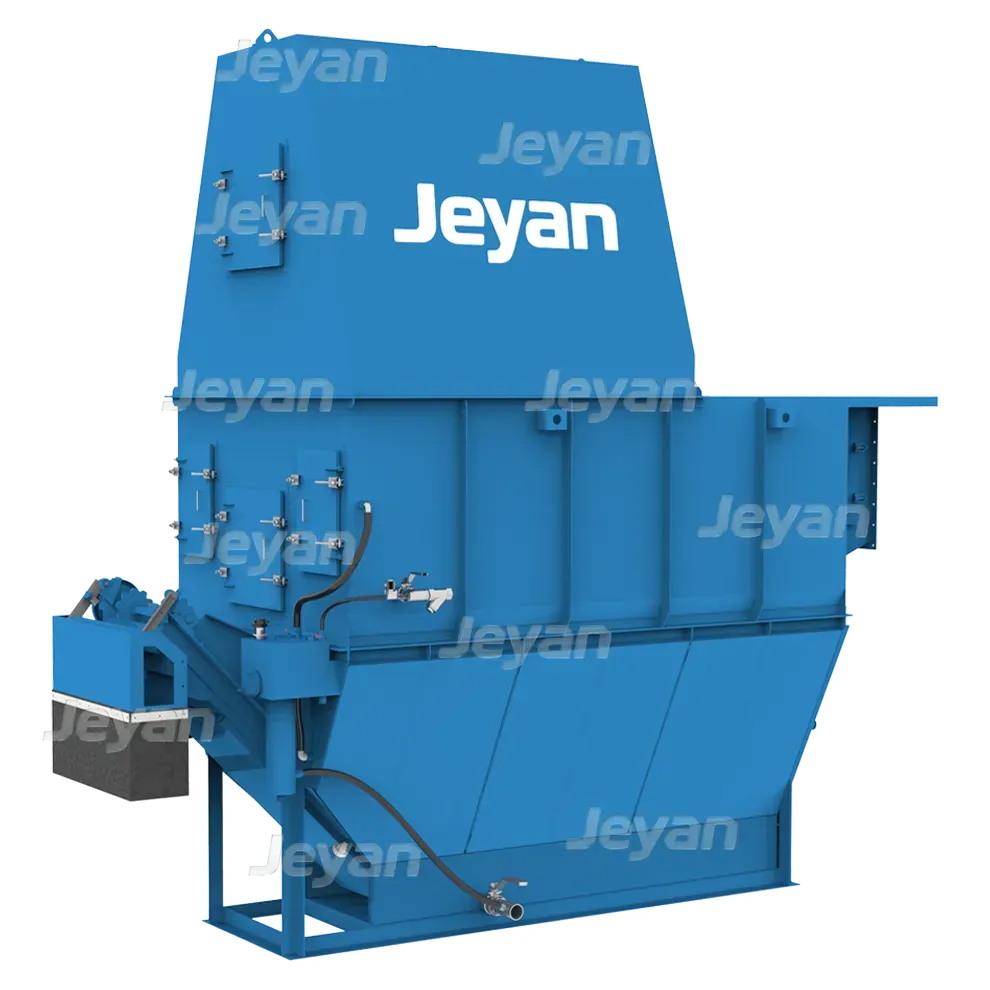

Multiple structures, more choices

The equipment can flexibly adjust its form and layout according to the on-site space conditions, adapt to different scene requirements, efficiently utilize space, and provide you with more suitable solutions

Technical Features

Venturi Rod Efficiency

The MDC series integrates an innovative Venturi rod layer that splits incoming air into multiple smaller channels. This design maintains steady flow with minimal pressure drop while intensifying the Venturi effect for superior dust capture - achieving the perfect balance between maximum efficiency and minimal resistance.

Three-Stage High-Efficiency

Our precision-engineered two-stage system begins with flow-straightening baffles for initial separation, followed by a dual-cyclonic stage that effectively isolates moisture from the air stream. This progressive approach prevents droplet carryover and ensures crystal-clear air output.

Massive Capacity Modular Design

With single units handling 300,000 m³/h and modular construction enabling dual-unit operation, the MDC-L series achieves system capacities up to 600,000 m³/h. This scalable solution effortlessly meets the demands of large-scale industrial applications.

Heavy-Duty Tank Construction

Engineered with reinforced walls and precision craftsmanship, our tanks offer exceptional durability. Available in carbon steel, 304 or 316 stainless steel, they withstand corrosive environments. Every weld undergoes rigorous testing to ensure leak-free reliability.

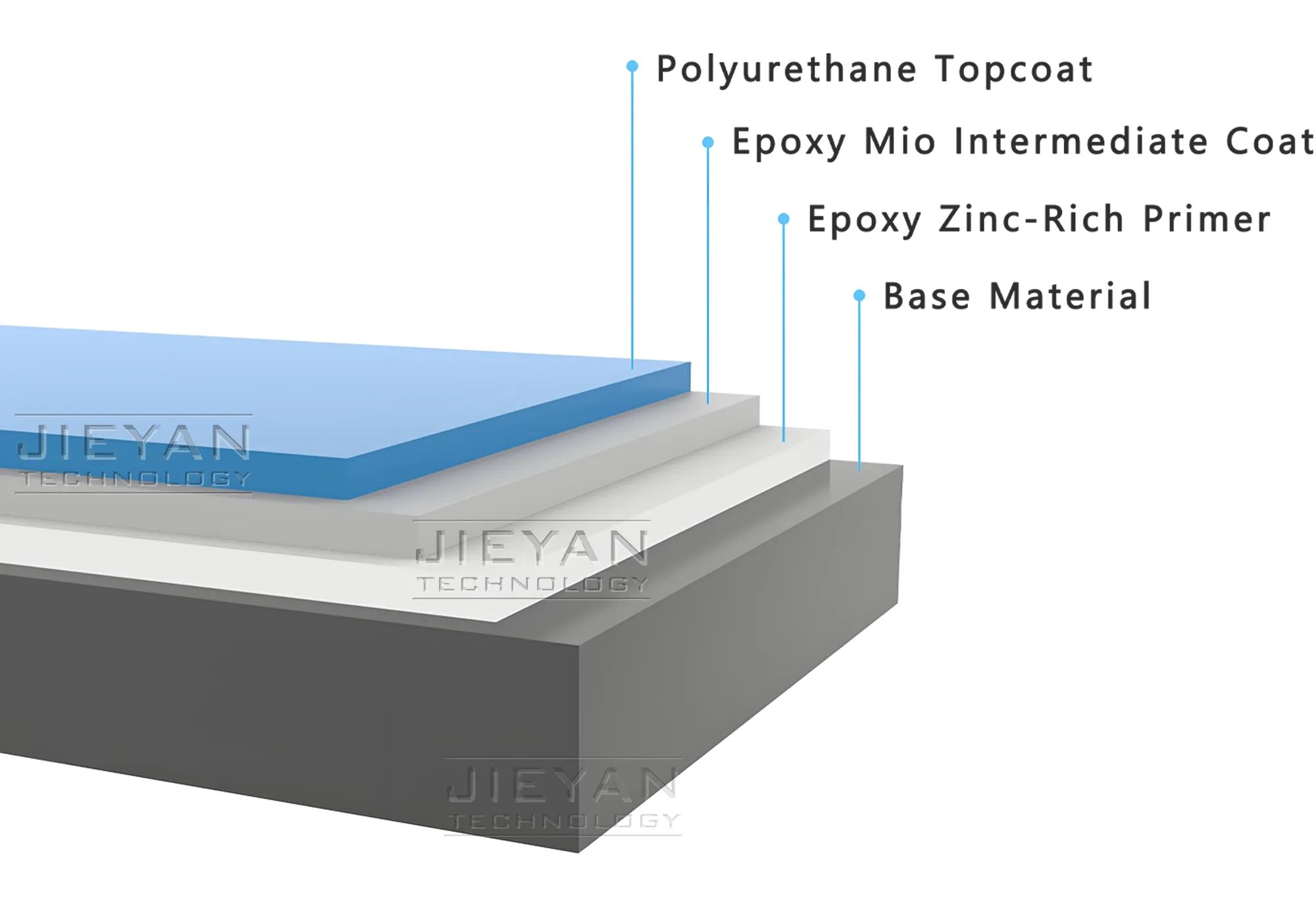

Advanced Protective Coating

Each unit receives thorough surface preparation through abrasive blasting before applying our multi-stage coating system. The 200μm protective layer of specialized primers and topcoats provides superior corrosion resistance for extended service life.

Related Cases

Related products

Contact Us

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219

Submit Successfully!

We have received your message and will contact you soon.