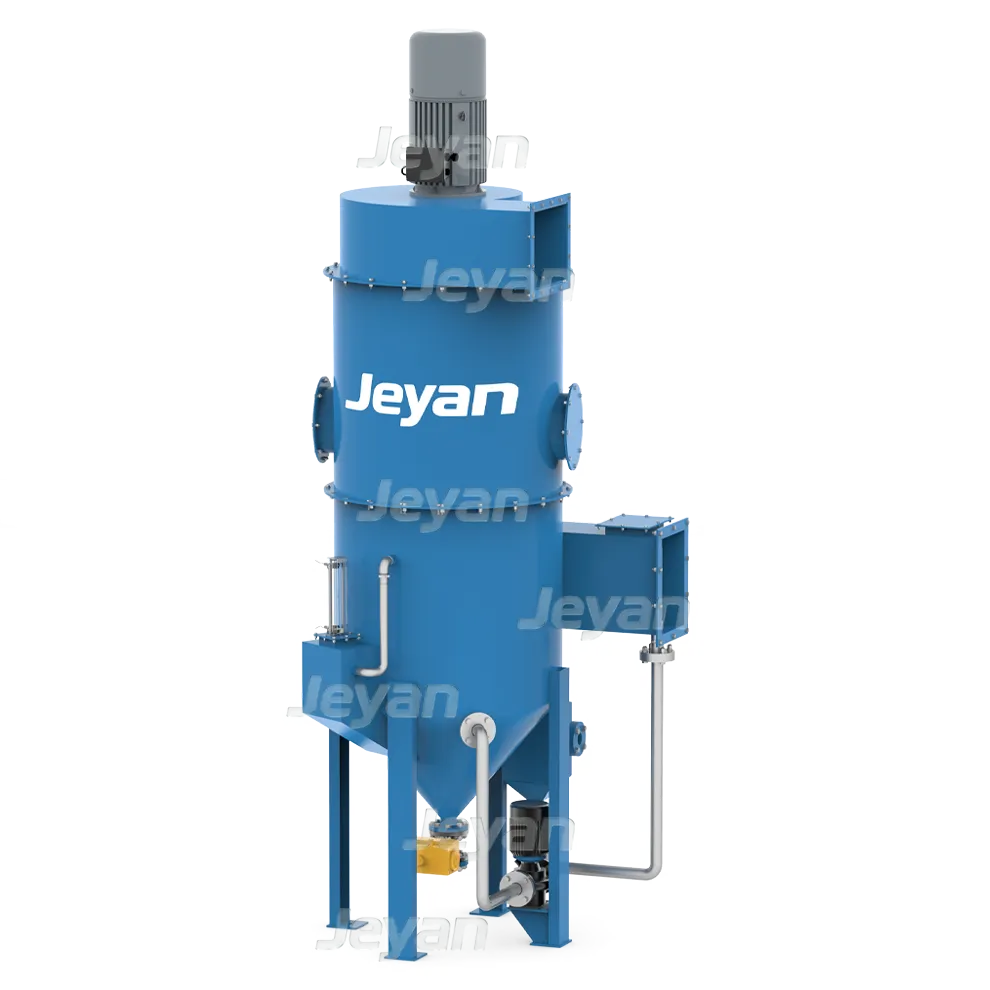

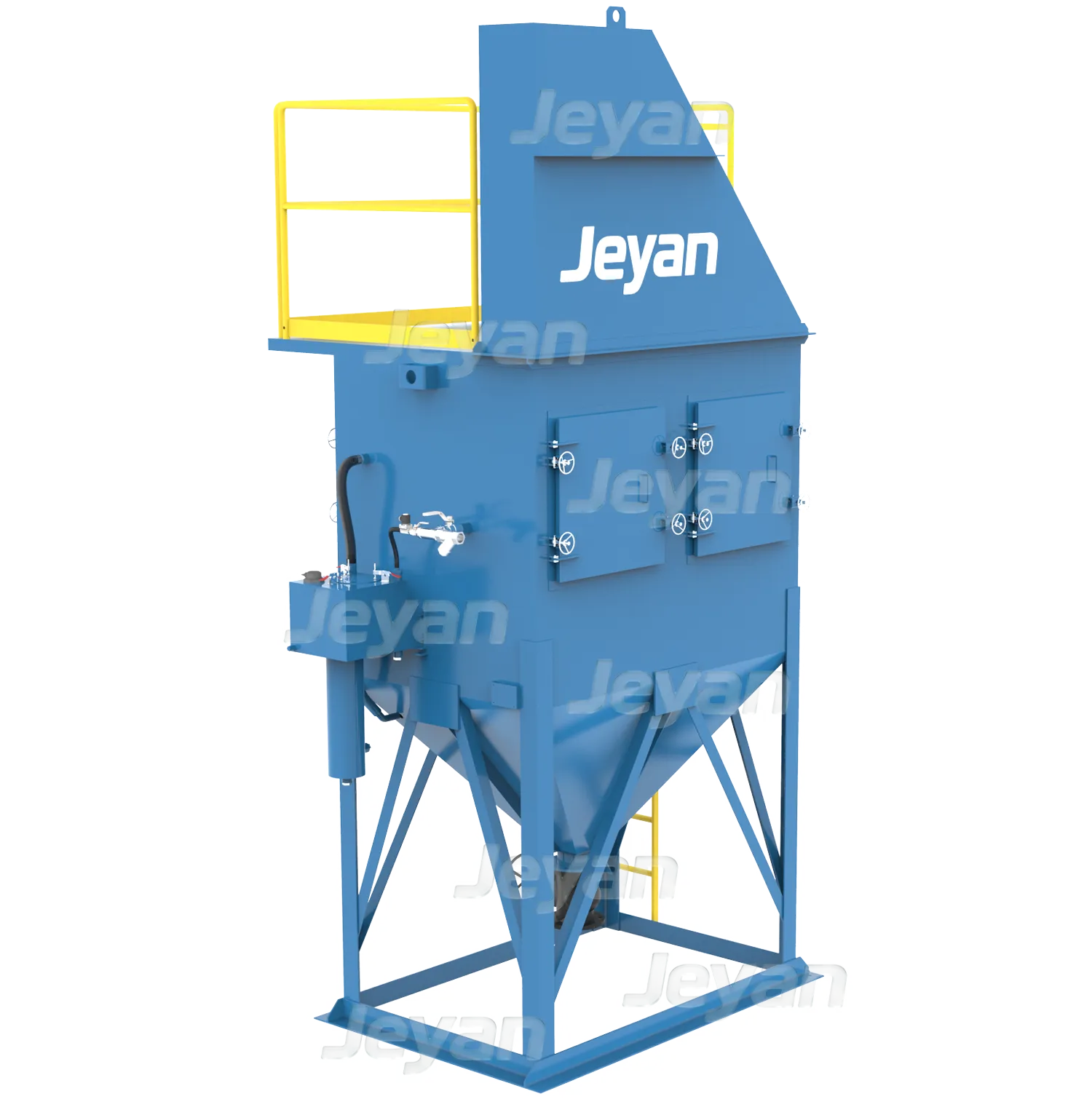

HDC Wet Collector

The N RotoClone is a highly efficient, low-maintenance wet centrifugal dust collector designed for a wide range of industrial dust and fume control applications. Combining robust construction with operational flexibility and minimal water consumption, it delivers reliable performance without the need for compressed air, replacement filters, or fabric bags. The system is capable of handling hot, moist, sticky, or even explosive dusts. Available in three sludge removal arrangements—manual, automatic, and continuous sluicing—it can be tailored to various process requirements. Proven in thousands of installations worldwide, the RotoClone N serves industries such as plastics, metals, chemicals, woodworking, and pharmaceuticals, offering a durable and efficient environmental solution that supports both productivity and sustainability.

Polishing dust

Viscous dust

Steam and oil fog

Flammable and explosive dust

Fiber / Fluff / Fabric dust

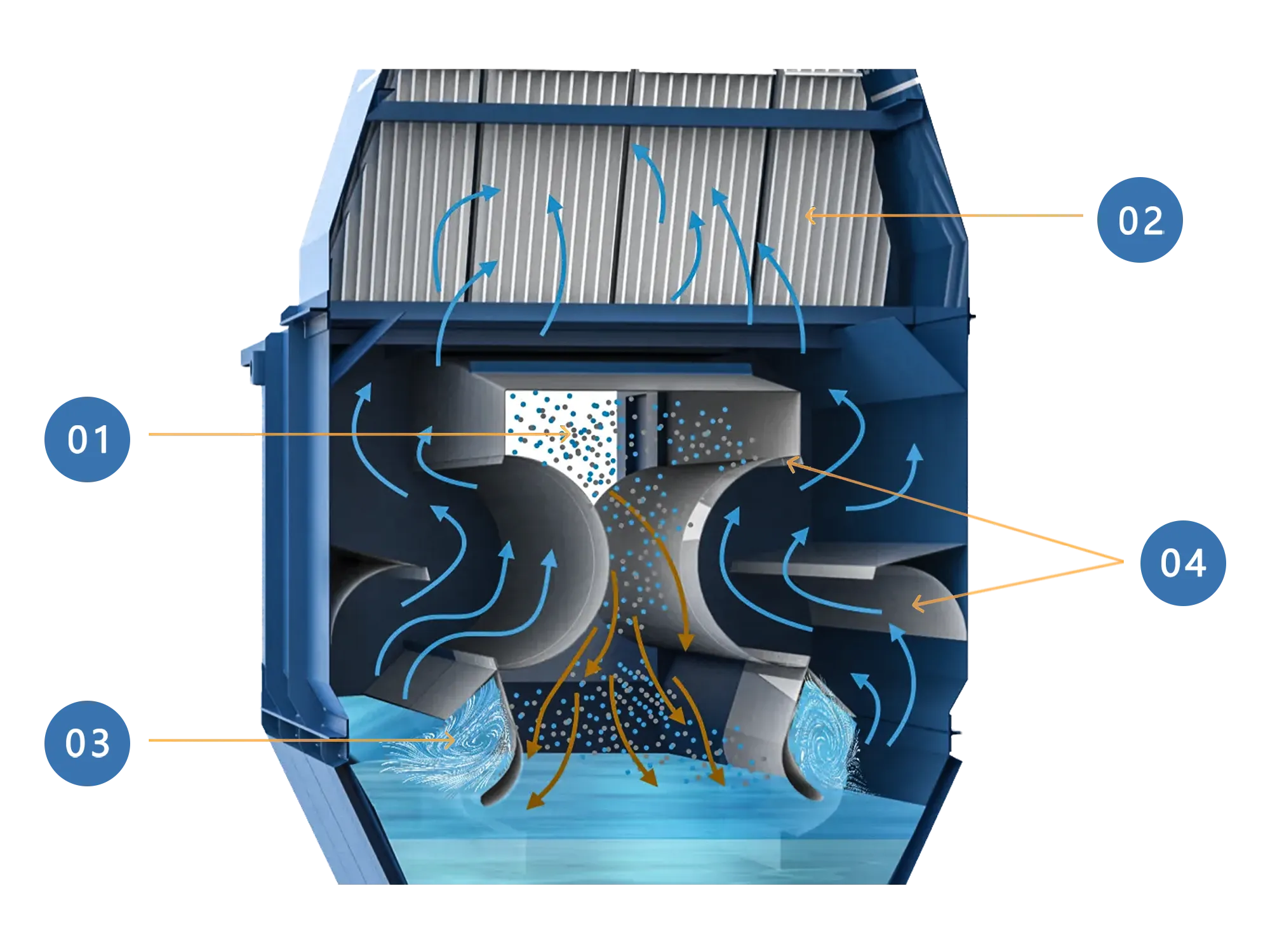

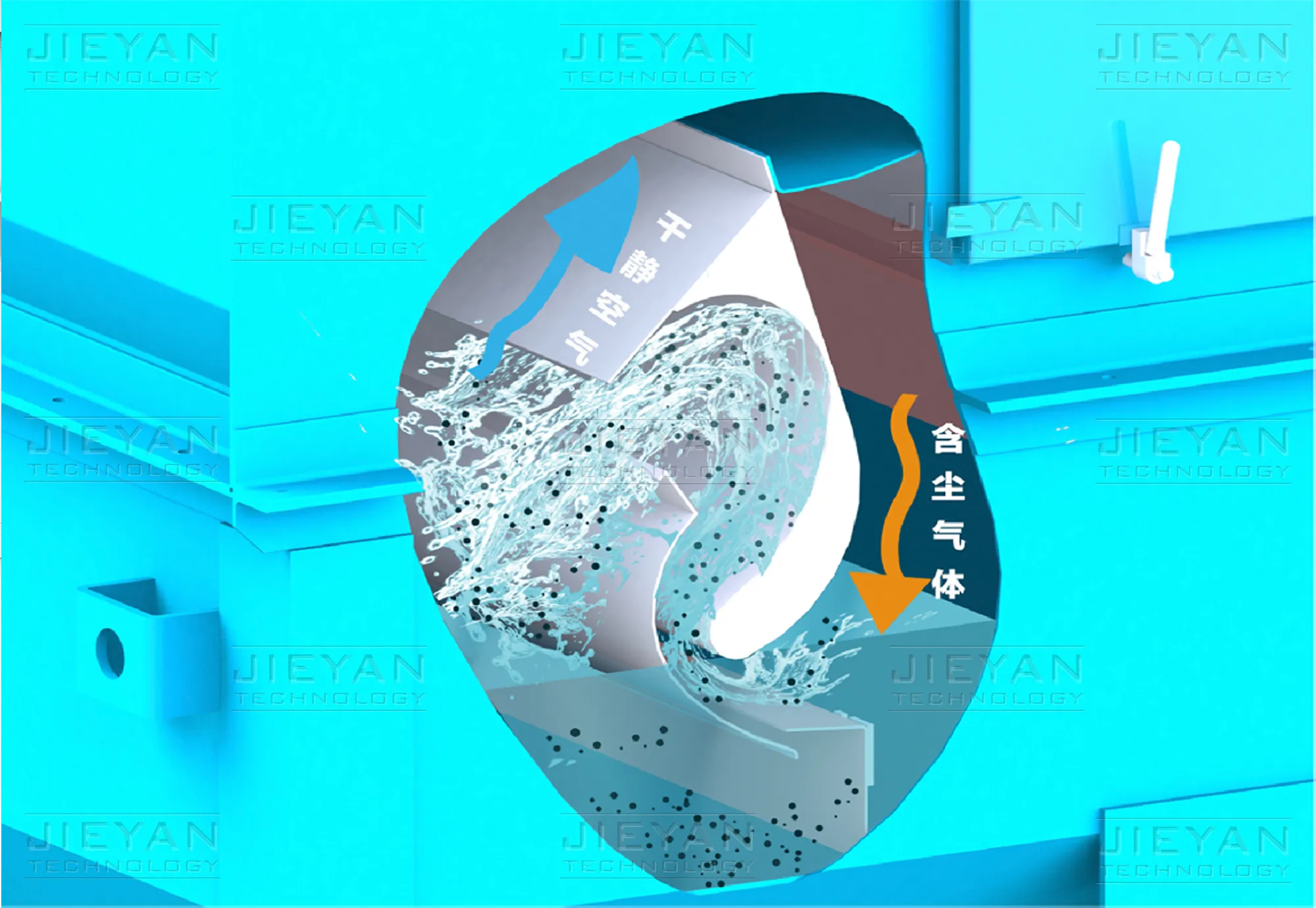

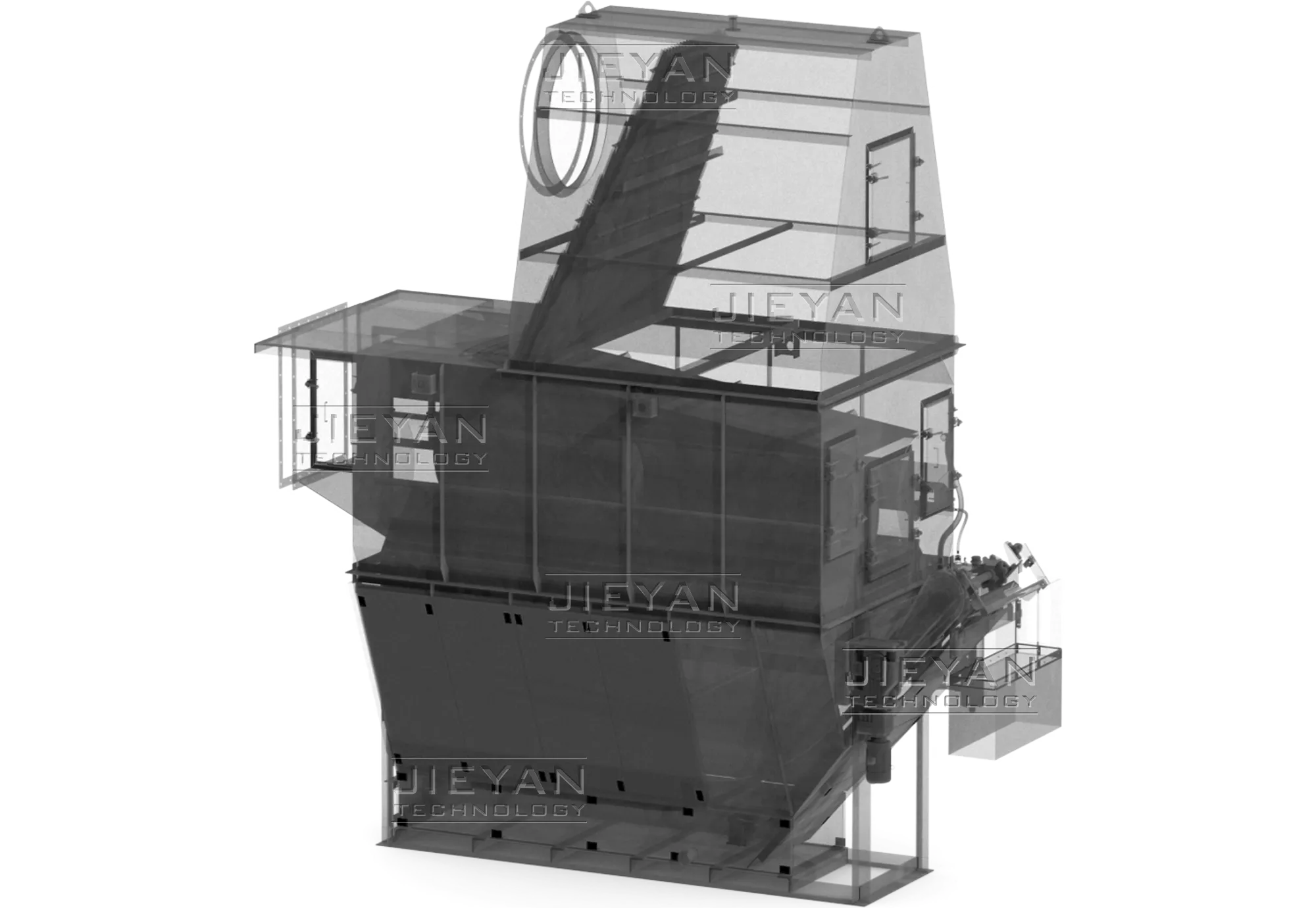

Structure and Principle

The N RotoClone operates on a centrifugal wet scrubbing principle. Dust-laden air enters the unit and passes through a specially designed rotor, which imparts a spinning motion to the gas stream. Centrifugal force throws particles toward the collector walls, where they penetrate a water curtain and are permanently captured. Clean air then passes through entrainment separators to remove moisture before discharge. Water is recirculated within the system, eliminating the need for pumps or nozzles; only minor makeup water is required to compensate for evaporation and sludge removal.

The collector consists of an inlet section, rotor assembly, entrainment separator, and water reservoir. Three hopper arrangements are offered: Arrangement B (manual sludge removal), Arrangement C (automatic sludge ejection), and Arrangement D (continuous sluicing). Designed for continuous operation with minimal maintenance, the RotoClone N provides a reliable and adaptable dust control solution for demanding industrial environments.

① dirtyairinlet

② water eliminators

③ impellers

④ baffle type water eliminators

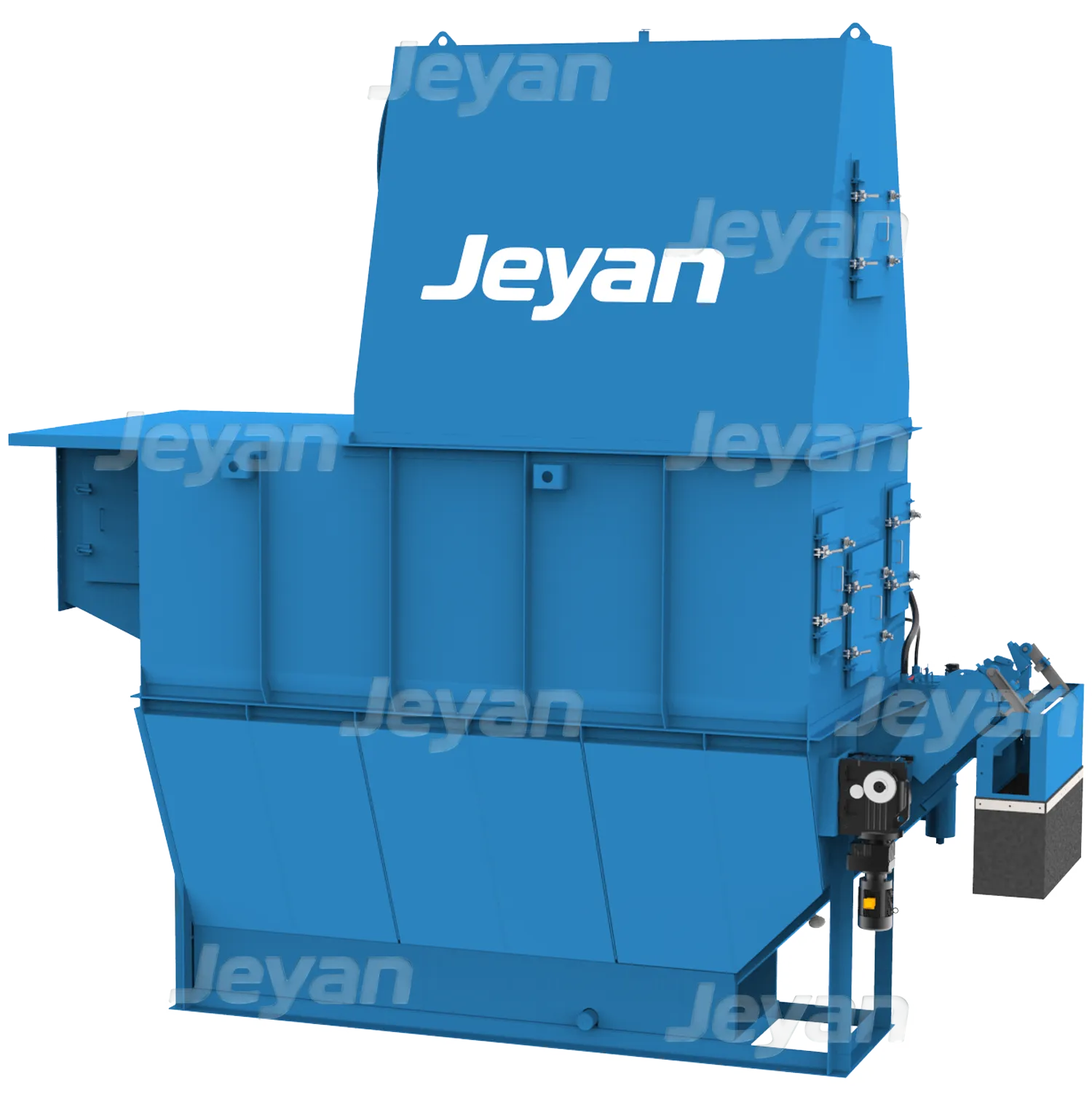

Multiple structures, more choices

Arrangement B – Manual Sludge Removal

Arrangement B, is designed for reduced height and low initial cost. Collected materials will be removed manually.

Arrangement C – Automatic Sludge Removal

Arrangement C, is designed to reduce manual removal of collected material. Collected materials will be removed by automatic drag-type sludge removal.

Arrangement D

Arrangement D, is designed to sluice collected material through the hopper into a process or disposal point. Sluicing may be continuous or intermittent.

Technical Features

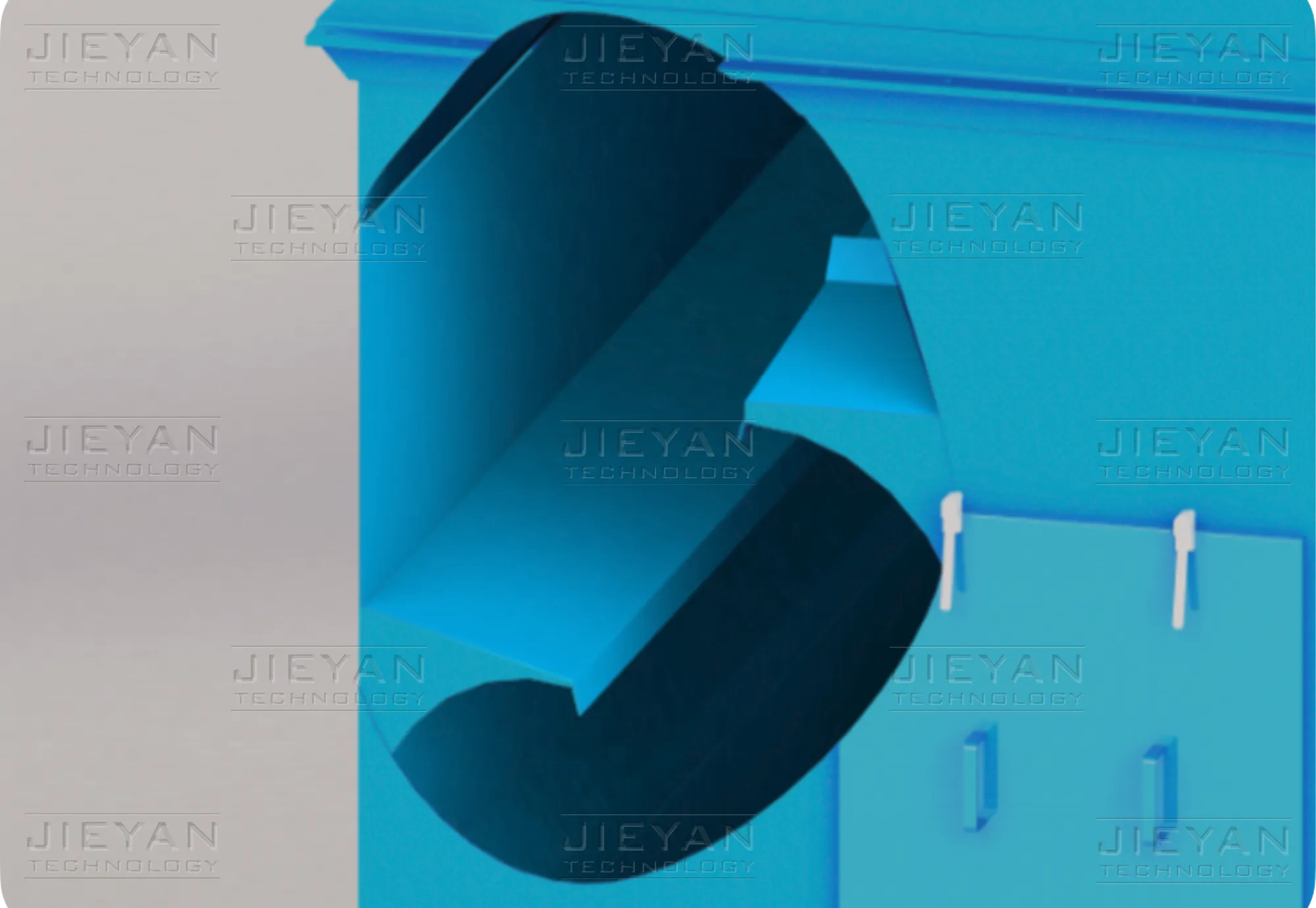

Efficient S-Shaped Flow Path Design

The HDC series incorporates an S-shaped flow path, aerodynamically optimized through simulation and refined by years of practical expertise. This advanced design delivers superior dust and air separation efficiency while maintaining minimal drag, ensuring highly economical and effective operation.

High-Efficiency, Low-Resistance Demister

Featuring a large-volume tank and a demisting zone velocity under 1.5 m/s, this system significantly enhances mist removal. Its three curved baffle plates are engineered for smooth airflow, providing high moisture separation with low pressure drop. The absence of mesh or complex plates entirely prevents clogging.

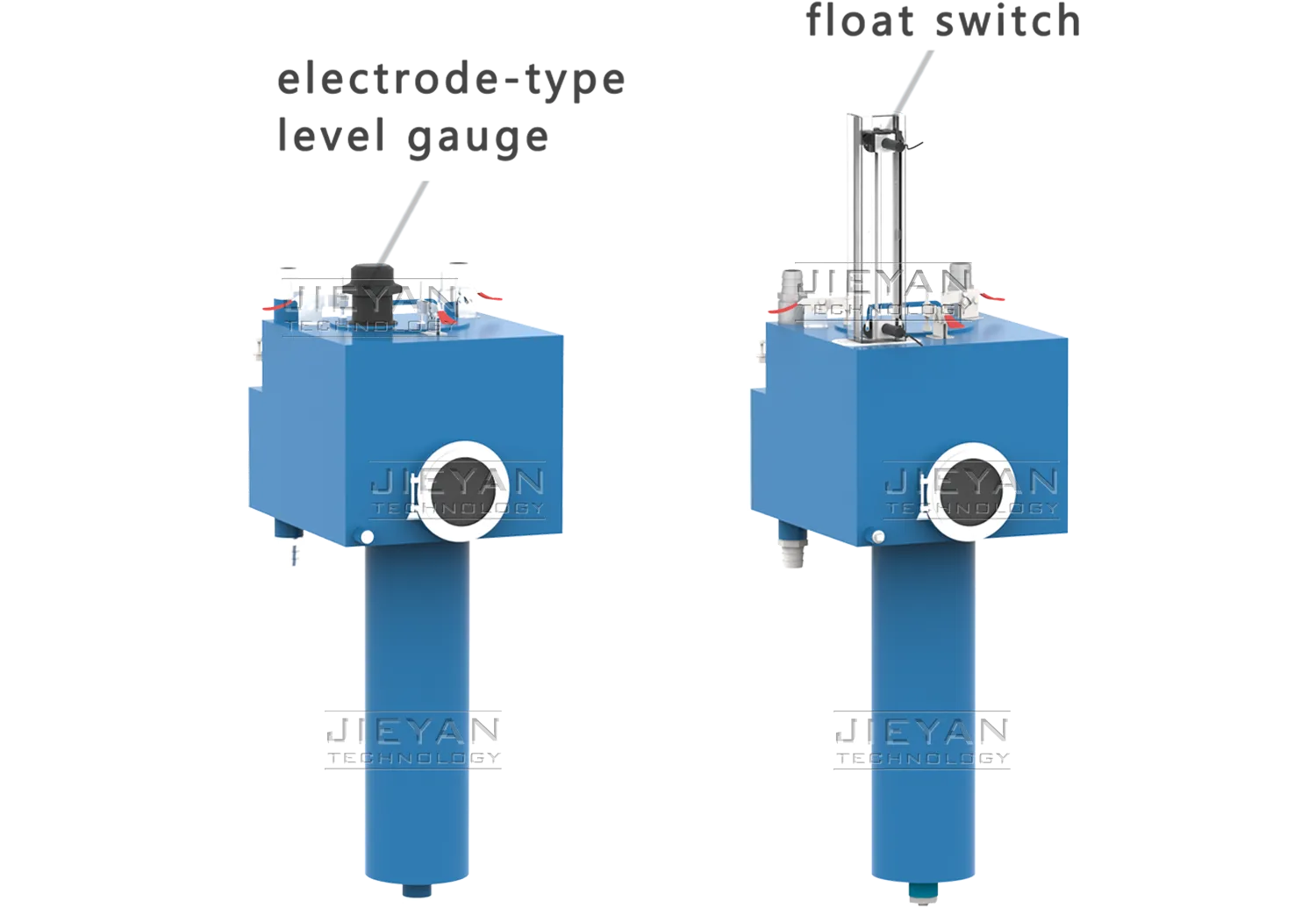

Reliable Water Level Monitoring

Compatible with both electrode and float-type level sensors, the system is interconnected to automatically manage water replenishment and provide dry-run protection. The float switch, being physically isolated from the liquid, remains unaffected by scaling or pH variations, ensuring long-term reliability and extended service life.

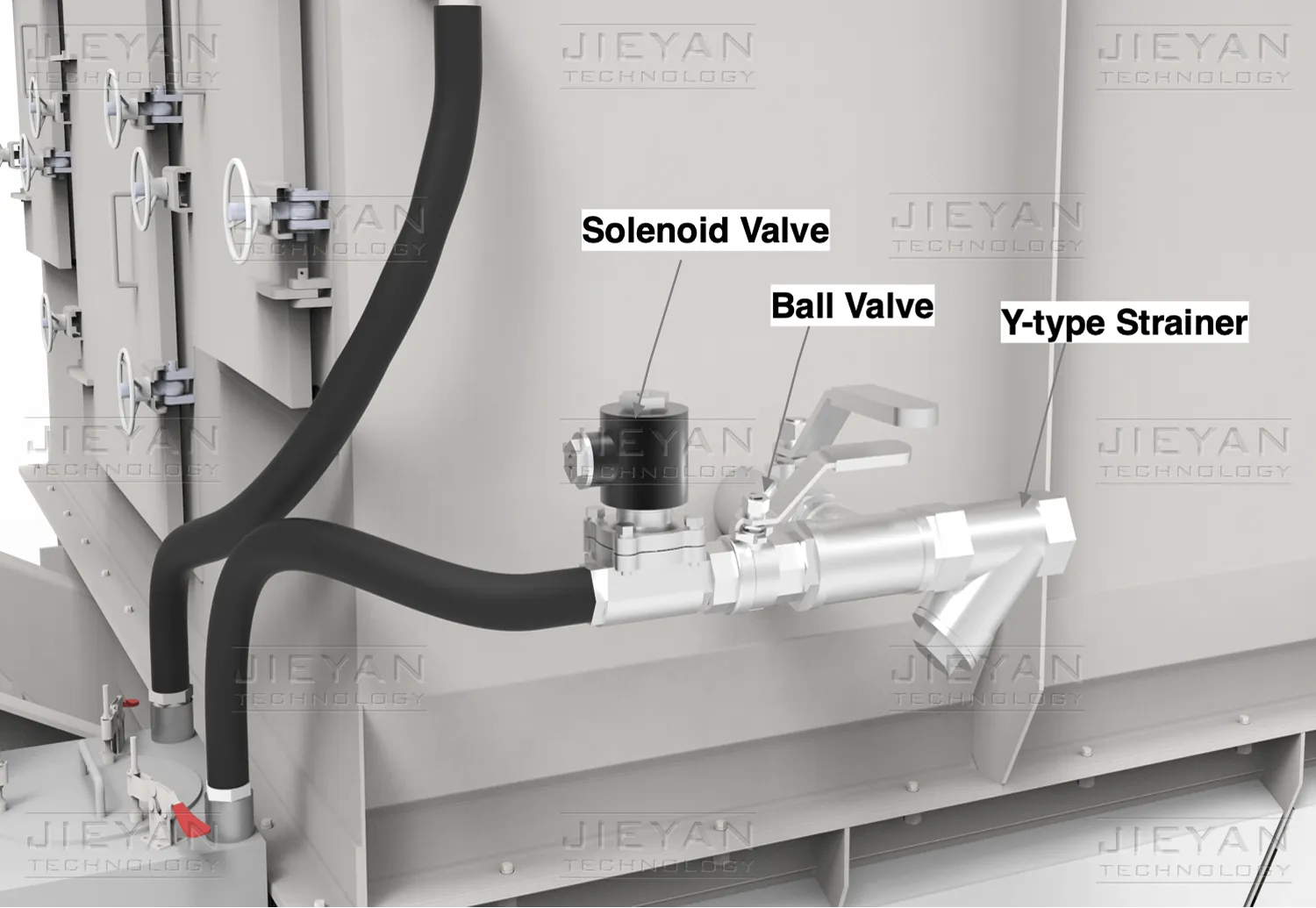

Fully Automatic Water Replenishment

Operating in either manual or automatic mode, the system includes an integrated pipeline filter to trap impurities and protect the control valve from blockage. Precision solenoid valves deliver dependable performance for continuous, stable operation.

Rugged and Long-Lasting Tank Construction

Built with reinforced walls and available in carbon steel, 304, or 316 stainless steel, the tank adapts to diverse environments. Every weld is rigorously leak-tested, guaranteeing a leak-free unit upon delivery and enduring reliability.

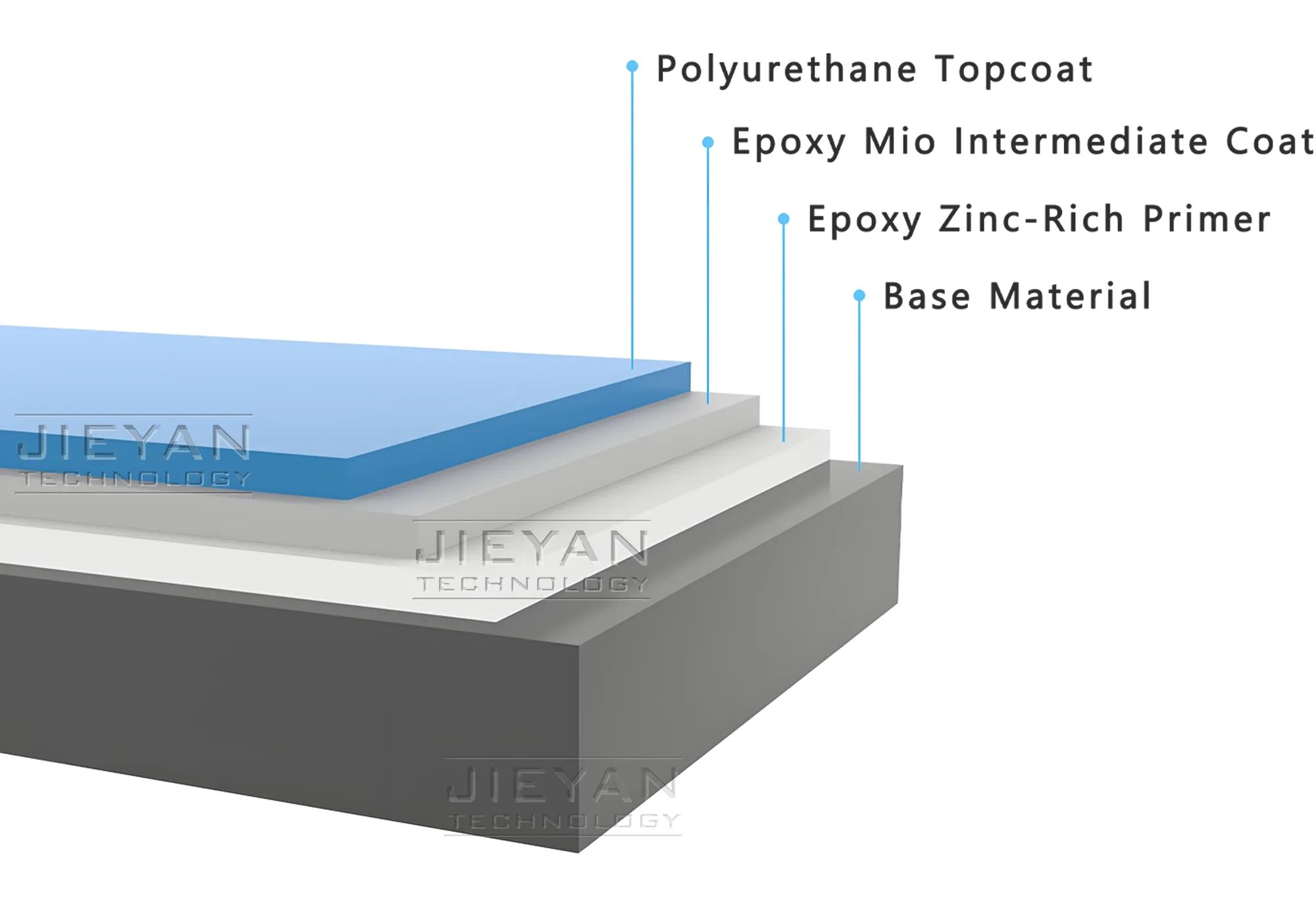

Superior Anti-Corrosion Coating

Each unit is mechanically abrasive-blasted to SA2.5 standard before applying an epoxy zinc-rich primer, a micaceous iron oxide intermediate coat, and a polyurethane finish. With a total coating thickness ≥200μm, it offers outstanding protection against corrosion and weathering.

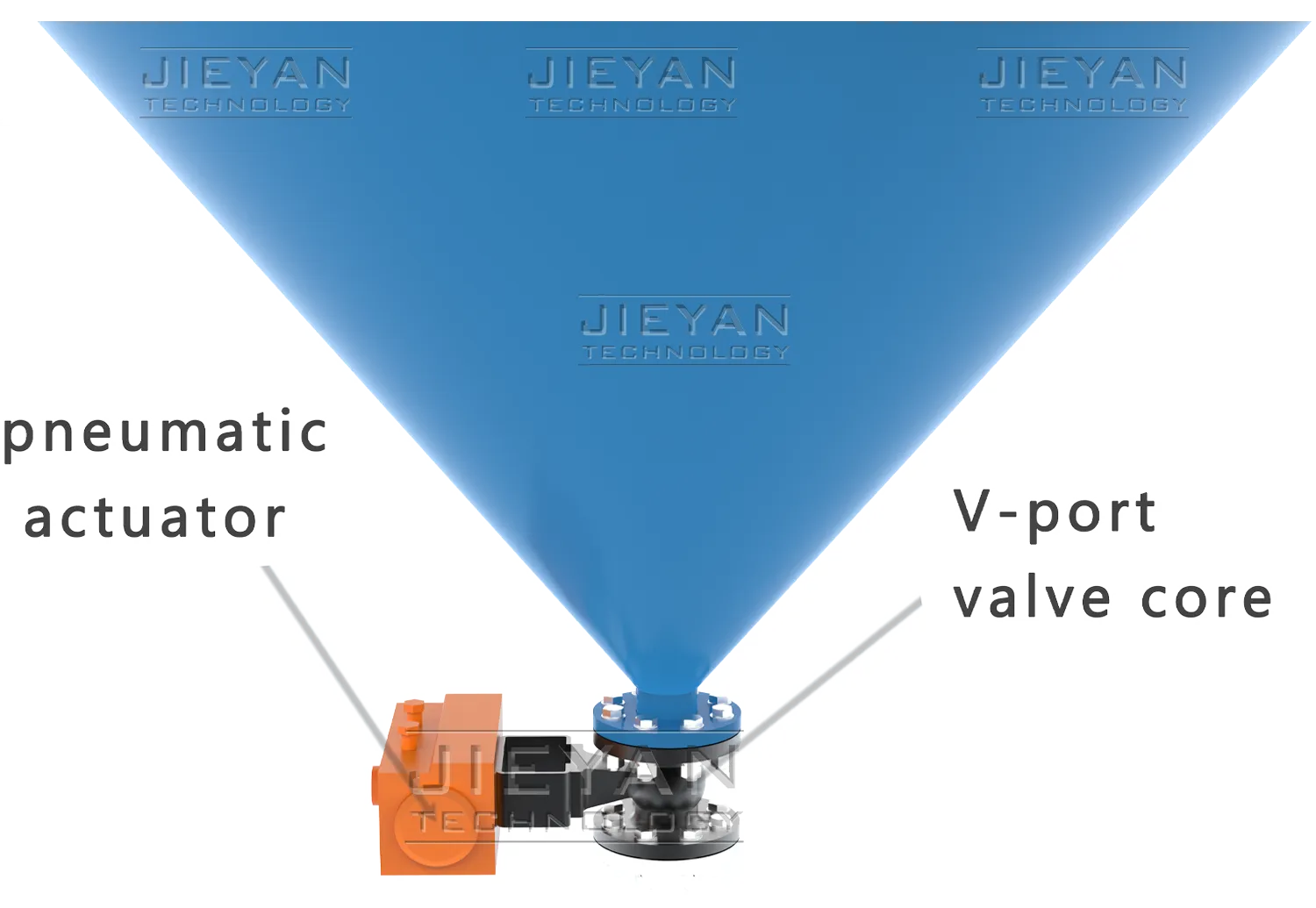

Wear-Resistant V-Port Drain Valve

The valve features a V-port core made of chromed 304 stainless steel, resisting abrasive wear and jamming. Its pneumatic actuator ensures quick opening and closing for powerful sediment flushing, with adjustable discharge intervals and duration to ease the load on downstream water treatment.

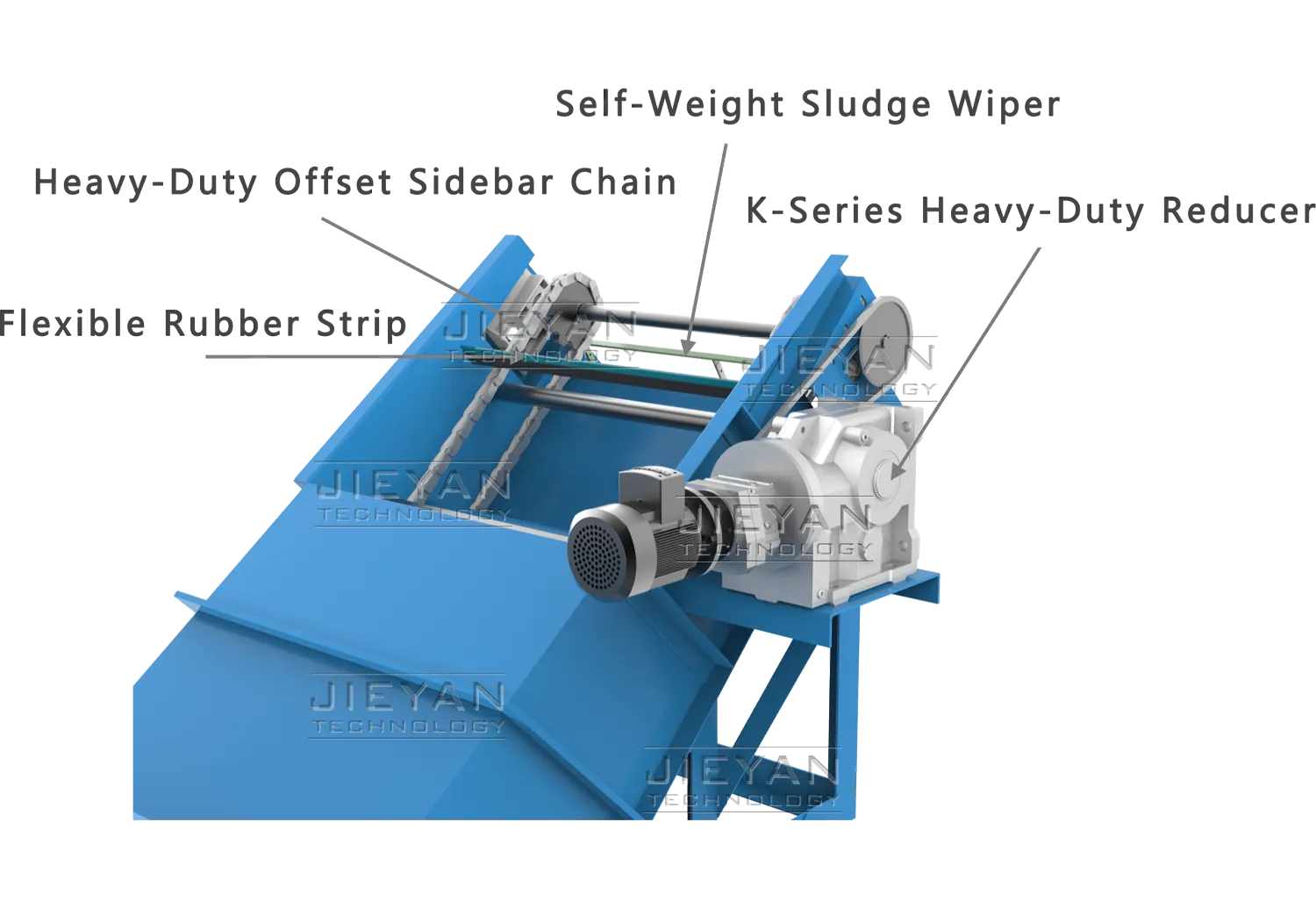

Heavy-Duty Sludge Scraper System

Equipped with a K-series heavy-duty reducer and robust scraper chains, the system is built to last. An automatic wiper at the outlet prevents sludge carry-back, and a bottom flexible rubber strip safeguards the tank floor. Submerged drive components require no maintenance for up to 36 months.

Optional Accessories

Optional PH Monitor

Optional Automatic Hydrogen Vent

Optional Hydrogen Concentration Sensor

Related Cases

Related products

Contact Us

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219

Submit Successfully!

We have received your message and will contact you soon.