TN Ship Loader

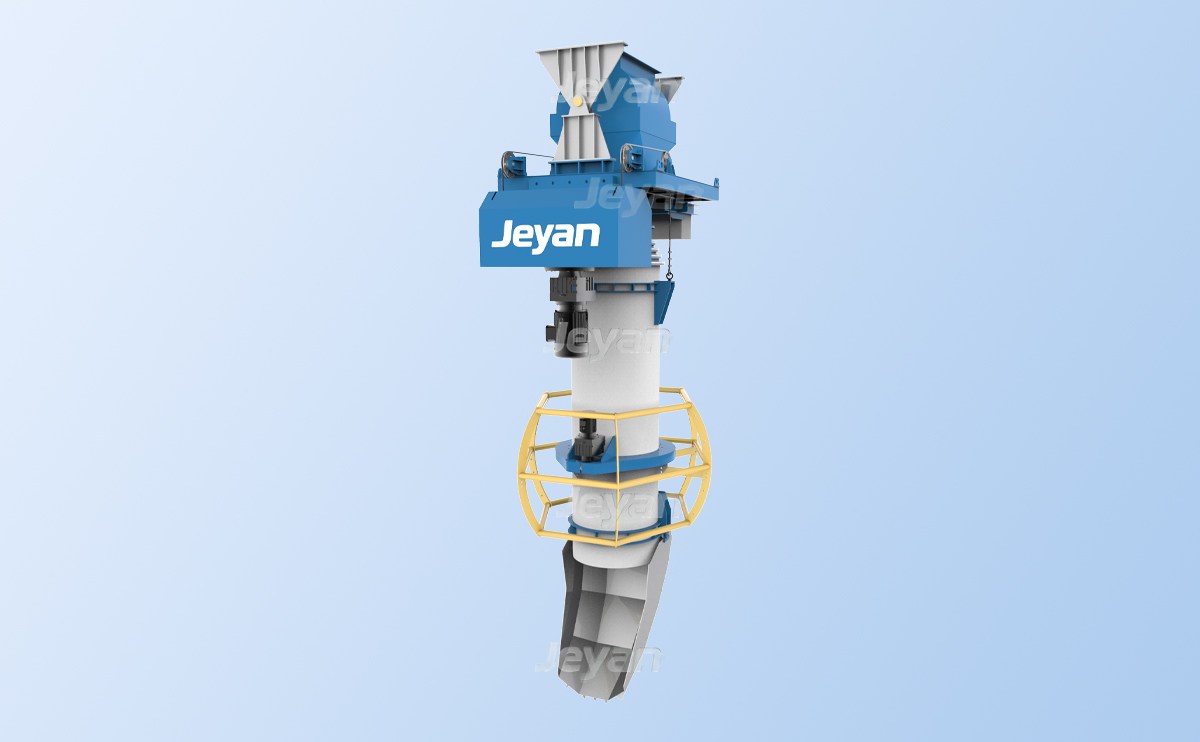

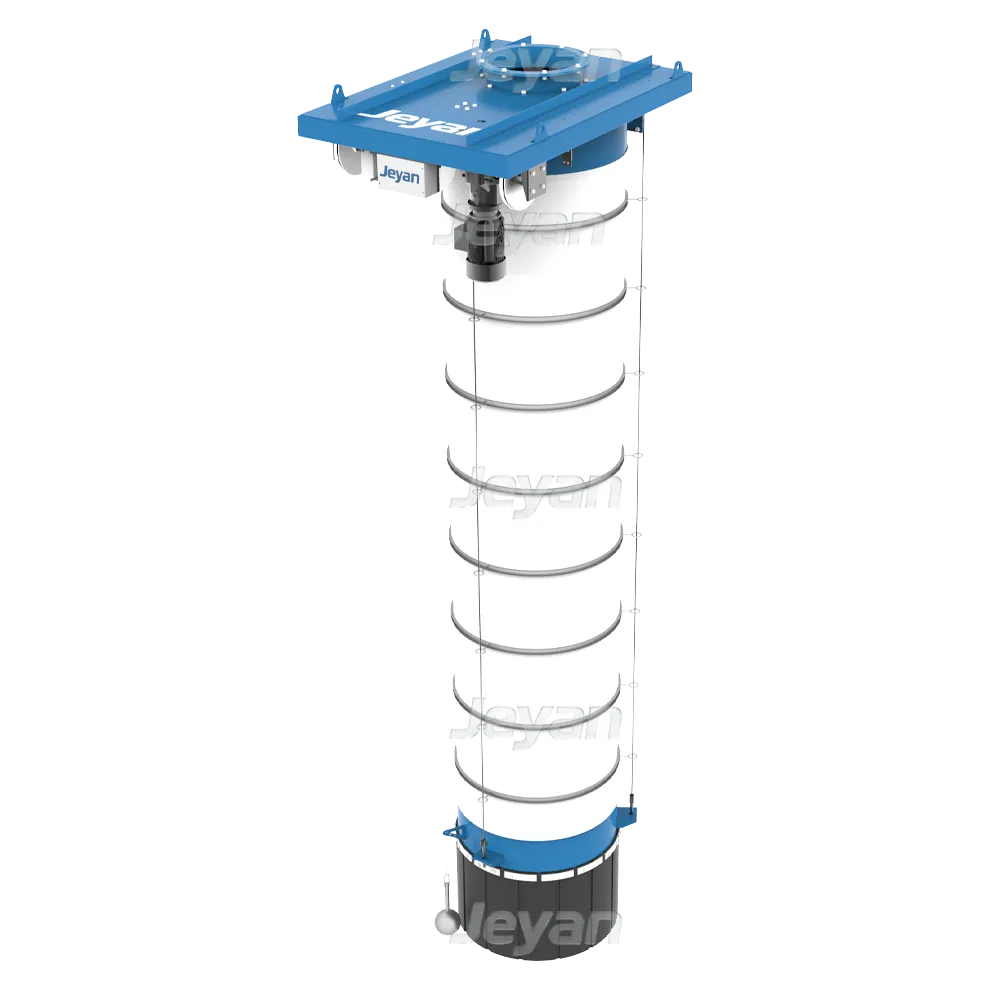

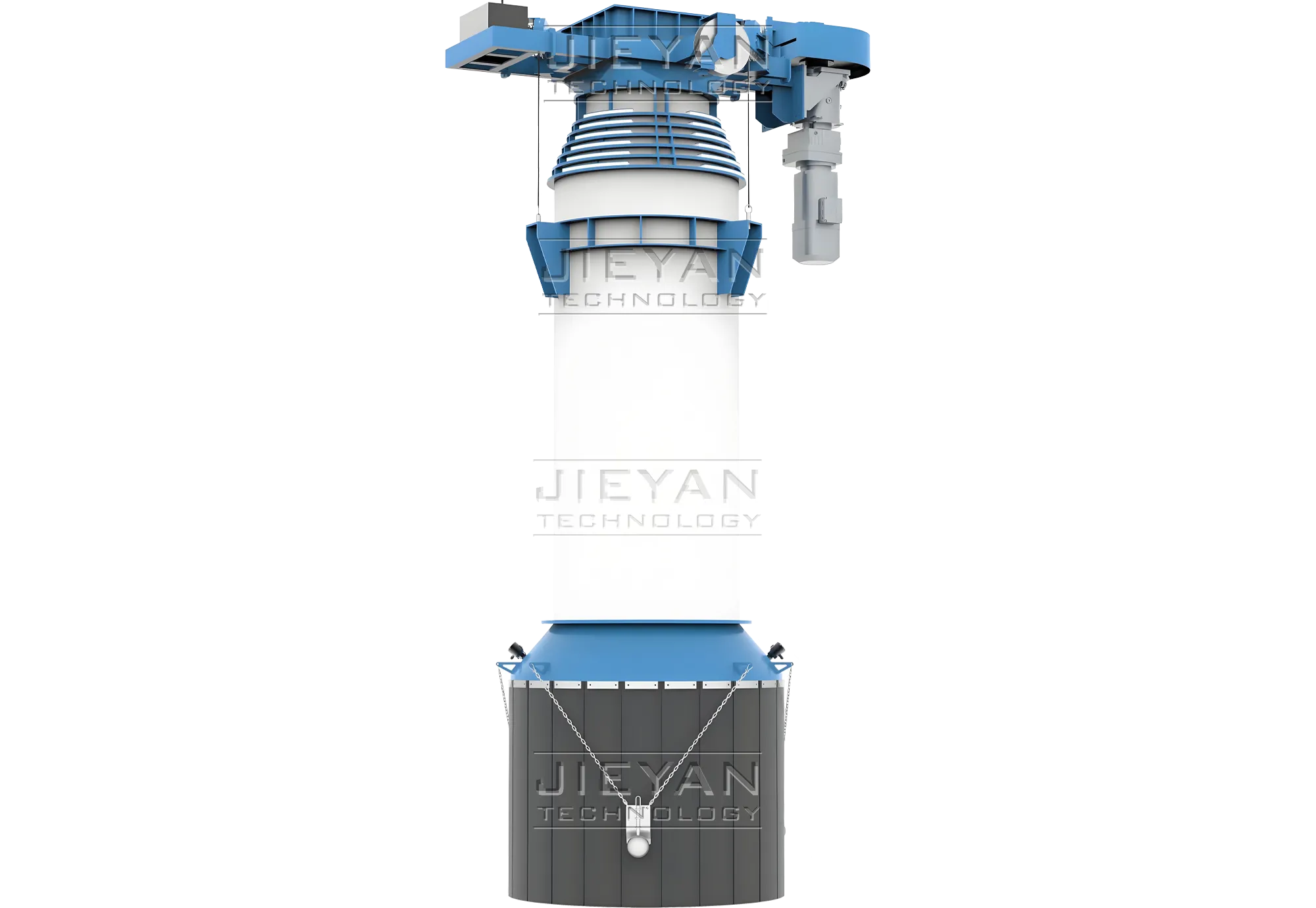

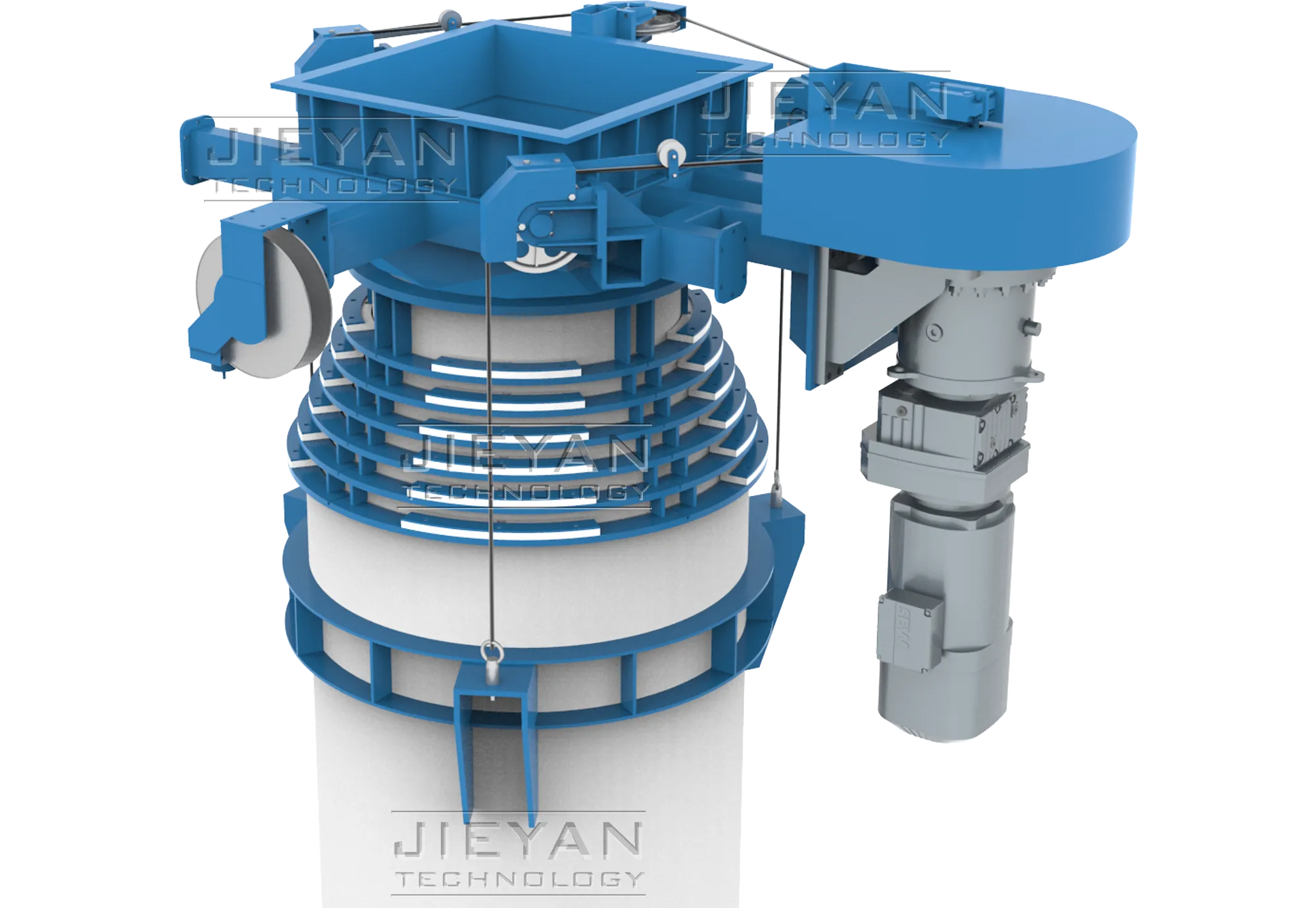

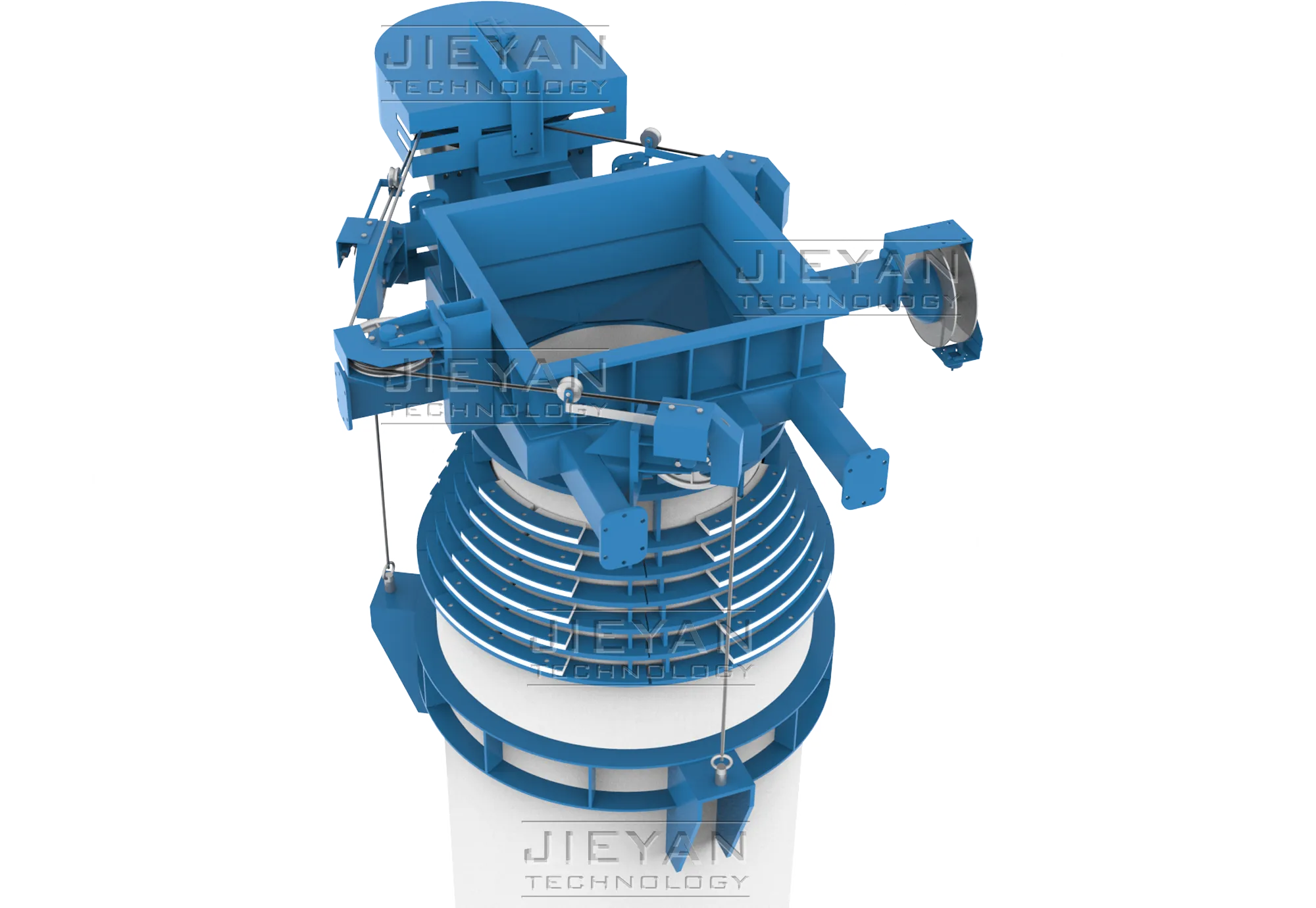

TN Ship Loader is designed specifically for loading and yard operations, and is a high-performance heavy-duty chute system. Compared with traditional heavy-duty chutes, the most significant feature of this series is the integration of the lifting mechanism on the top frame of the chute, achieving an integrated design of the lifting mechanism and chute. This innovative structure makes the chute system a complete whole, which can be assembled and tested before leaving the factory to ensure reliable operation and complete functionality of the entire system. After the equipment arrives at the customer's site, there is no need for additional debugging, and it can be quickly embedded into the existing material transfer system and immediately put into production use. The integrated design also saves installation space, making the system layout more compact and reasonable.

Port loading

Ore loading

Mine yard

Mineral powder loading

Port bulk loading

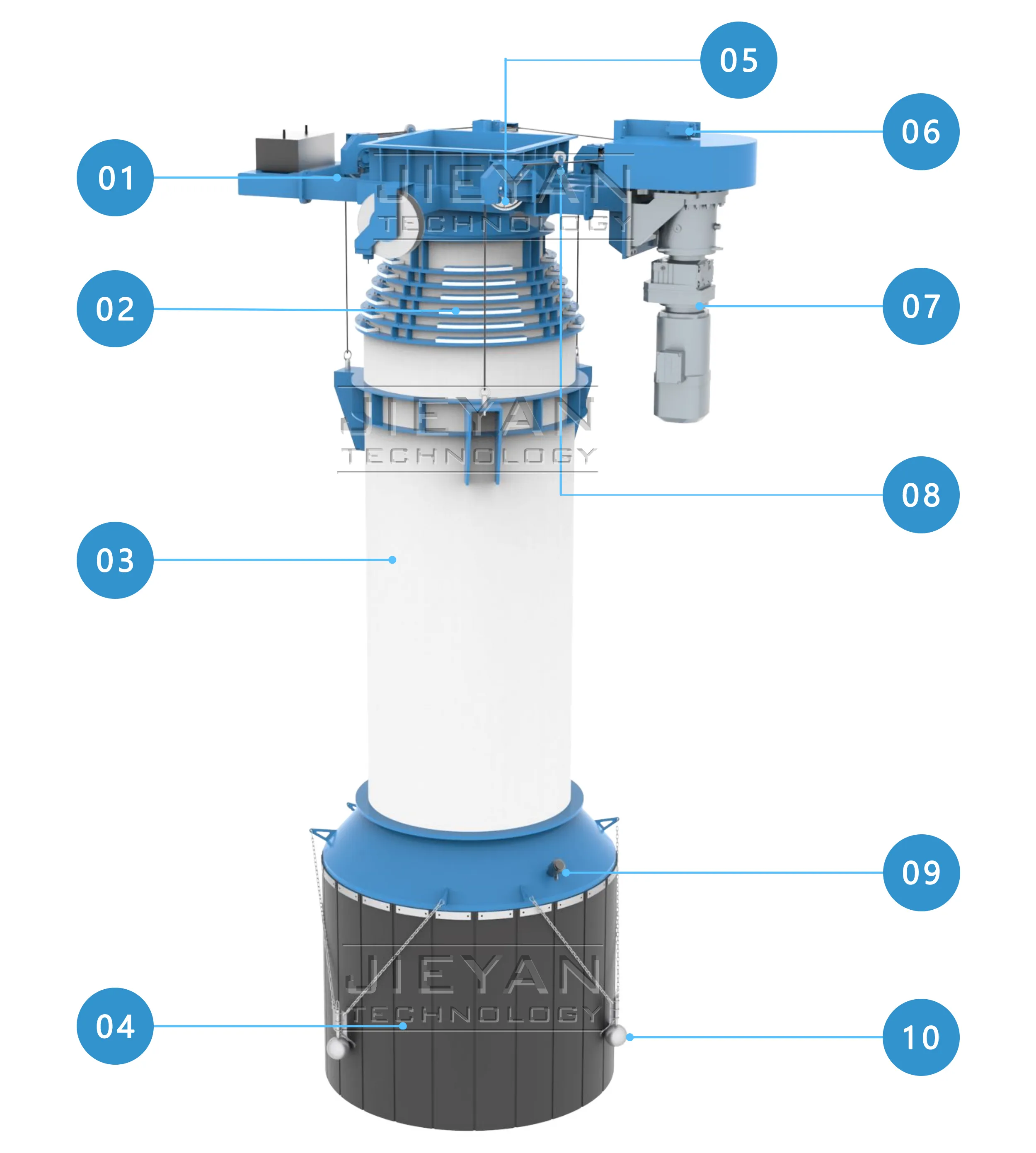

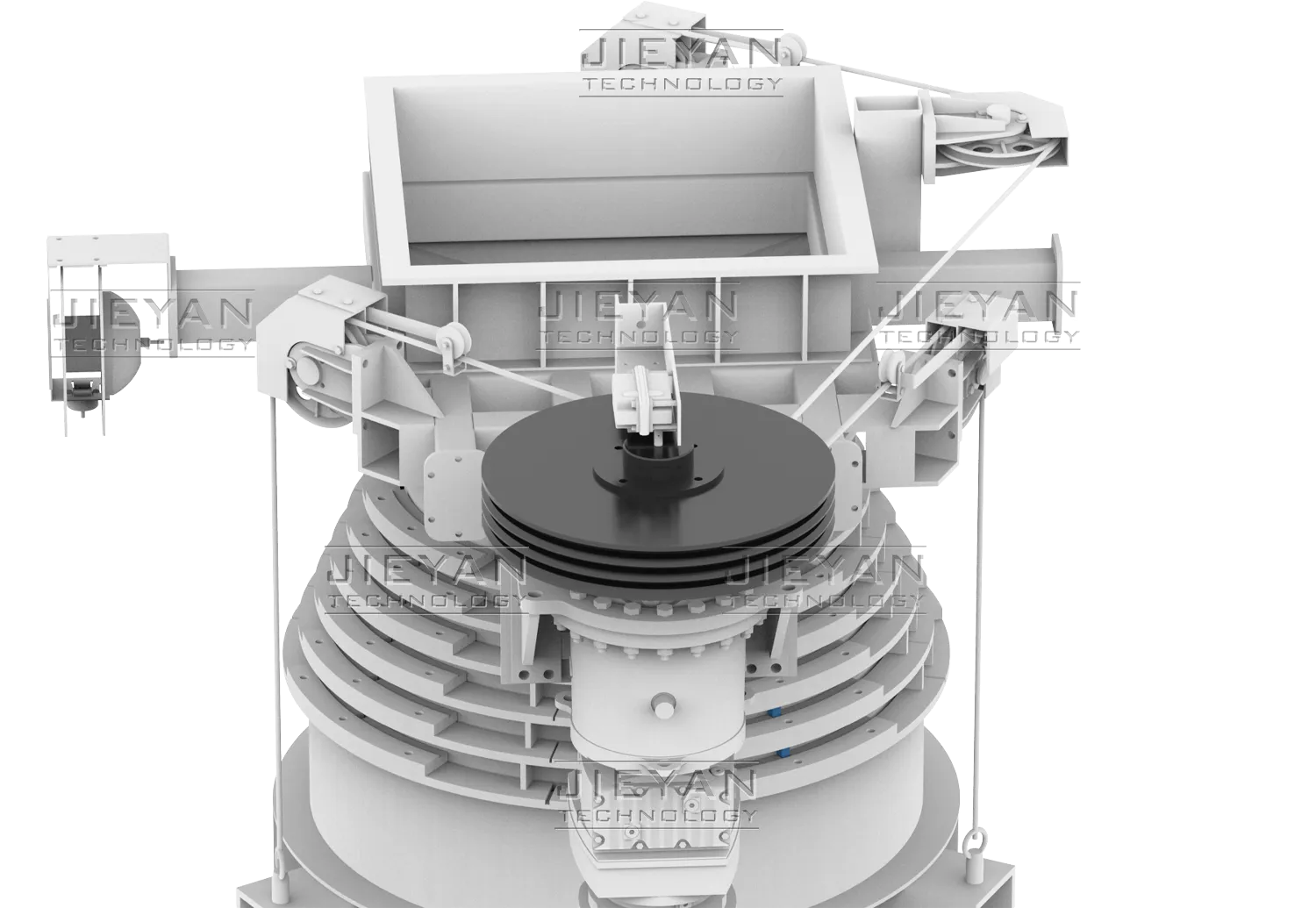

Structure and Principle

① Top Frame

② Tube Guide Ring

③ Wear-resistant Tube

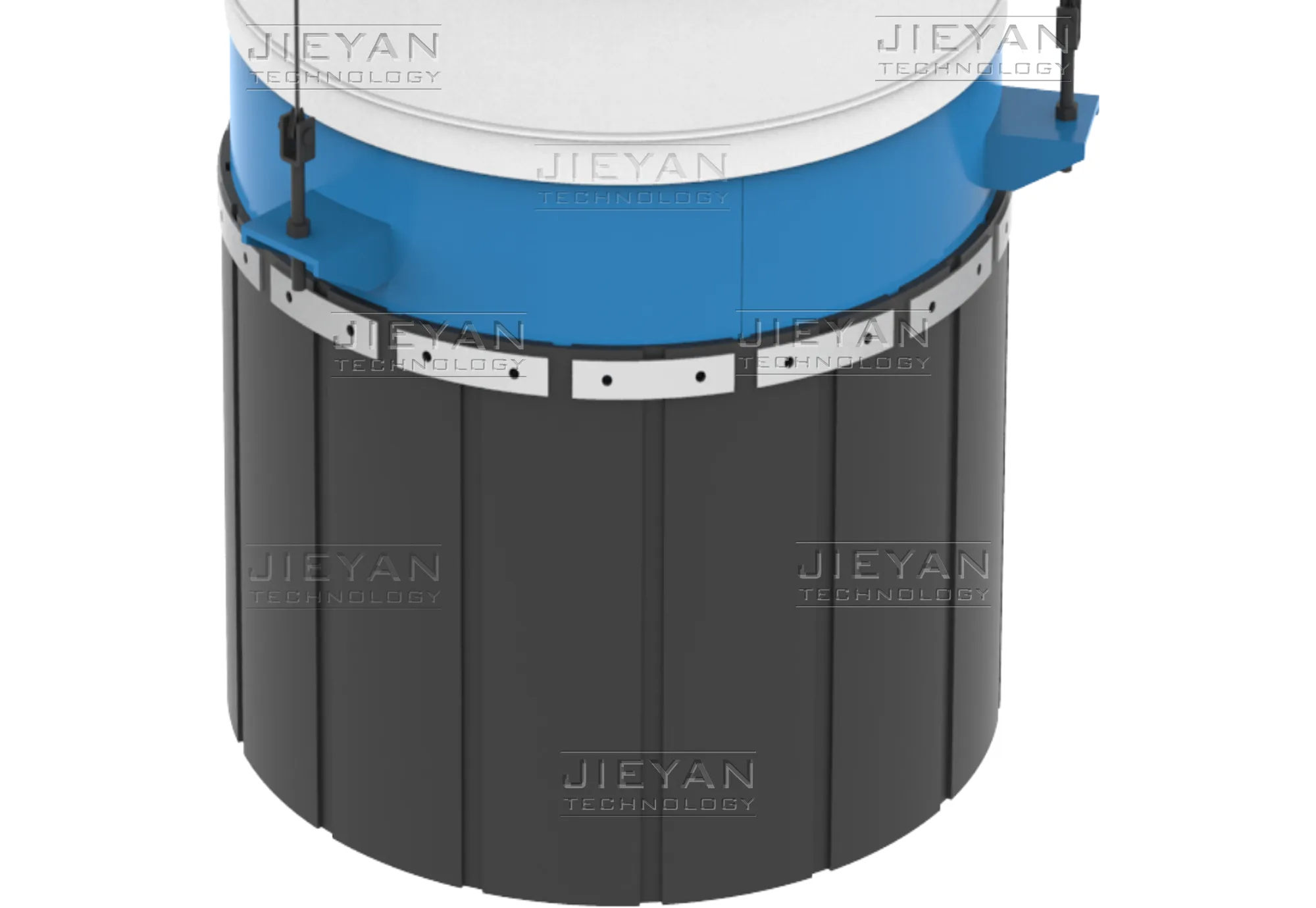

④ Rubber Skirt

⑤ Sheave

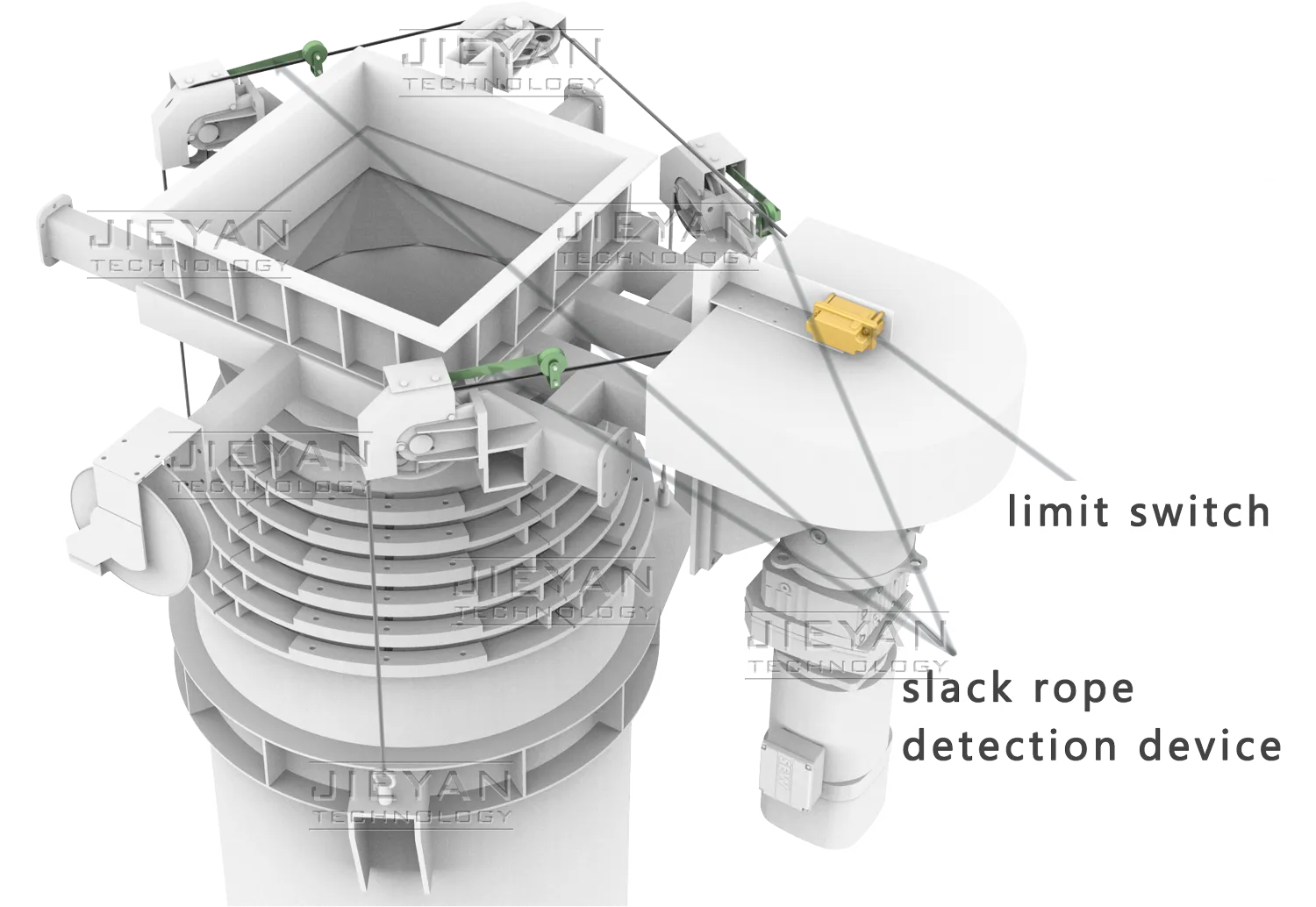

⑥ Rotary Limit Switch

⑦ Winch device

⑧ Rope Slack Switch

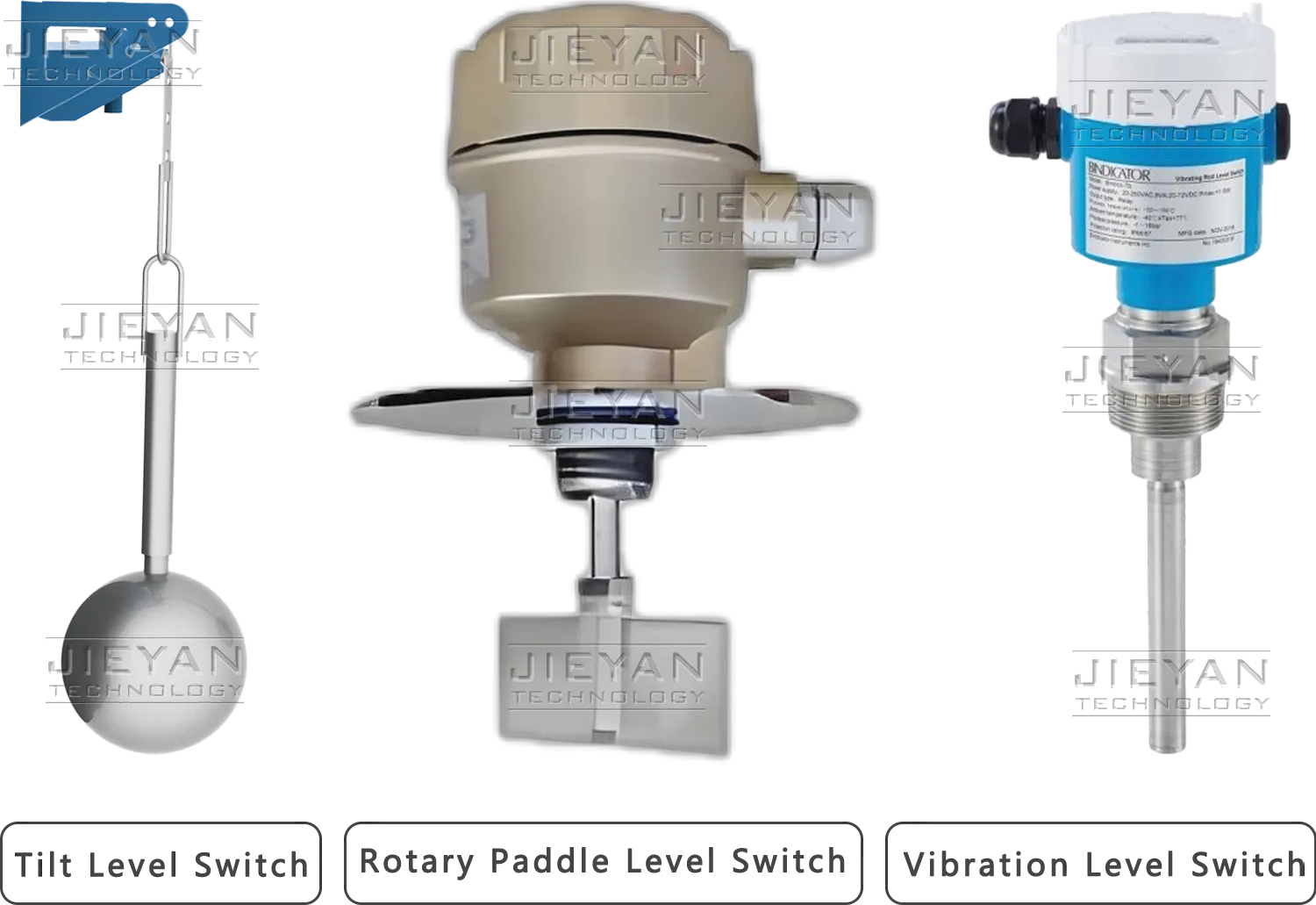

⑨ Material Level Switch

⑩ Tilt Switch

Technical Features

High Capacity & Extended Reach

With a handling capacity of 6000m³/h and maximum extension of 30 meters, this system delivers the performance needed for most ship loading and stockpiling operations.

Compact Integrated Design

The unified construction combining lifting mechanism and spout body creates a rigid, space-saving solution that simplifies installation and integration.

Triple-Rope Winch Drive

Our three-rope winch system with multiple lifting points ensures exceptionally smooth operation. Combined with a planetary gearbox delivering over 96% efficiency and high overload capacity, it's built for demanding heavy-duty applications.

Reinforced Core Components

Heat-treated and precision-finished shafts and winches provide smooth surfaces that extend wire rope life. All machined parts feature zinc plating for superior wear and corrosion resistance.

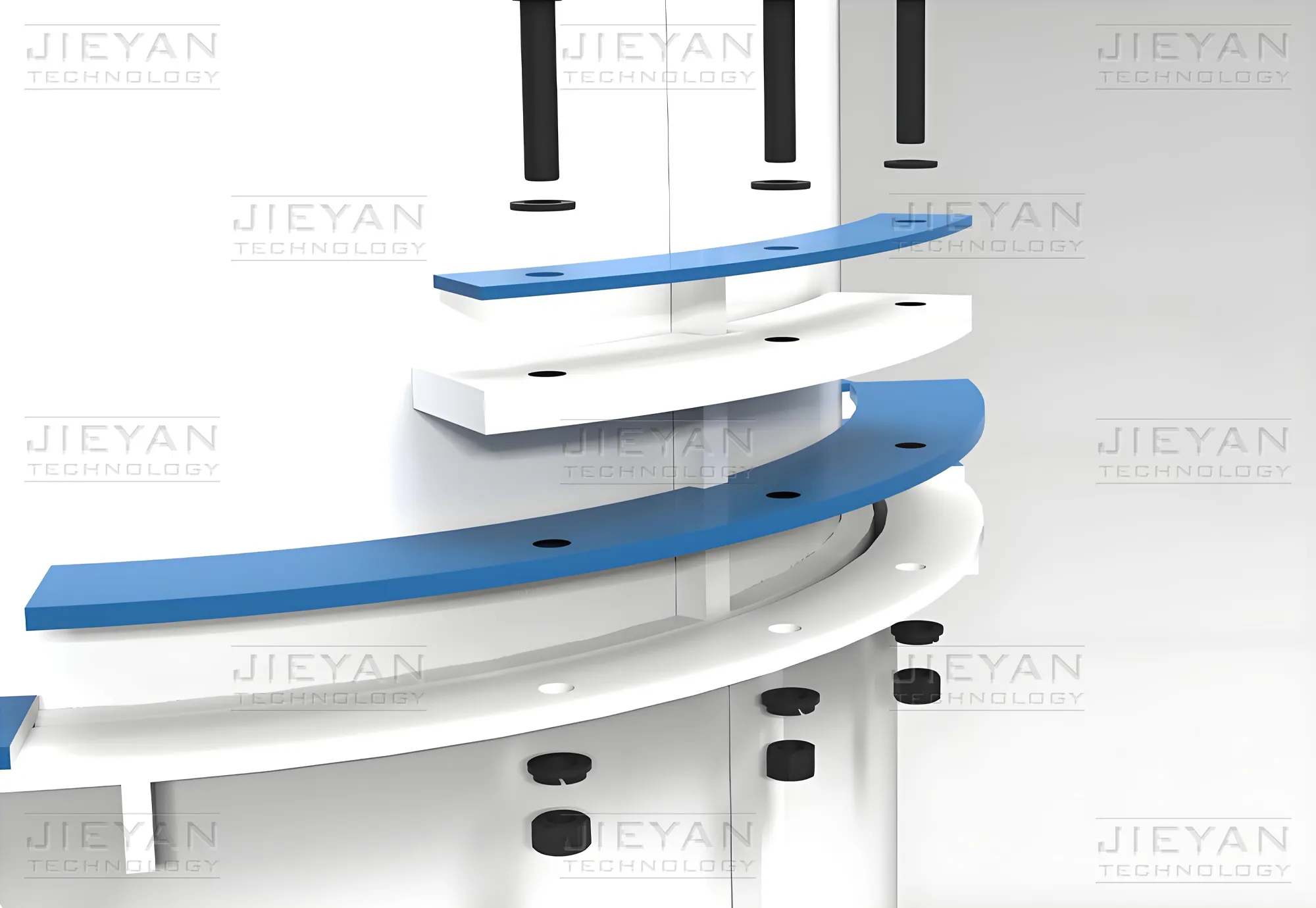

Modular Spout Design

Featuring split clamping flanges for easy section replacement and UHMWPE guide rings that provide wear resistance and self-lubrication for smooth telescoping action.

Configurable Wear Protection

Standard Q355B construction with optional NM abrasion-resistant steel, stainless steel, or specialized linings including ceramic, UPE and tungsten carbide hardfacing for extreme wear conditions.

Smart Safety Systems

Programmable limit switches with backup settings and standard slack rope detection prevent overtravel and derailment for failsafe operation.

Flexible Level Monitoring

Multiple level switch options including tilt, rotary paddle and vibration types provide accurate monitoring for various materials and installation requirements.

Double-Layer Rubber Skirt

Reinforced rubber skirt creates a tight seal with container outlets, effectively containing dust to meet environmental standards.

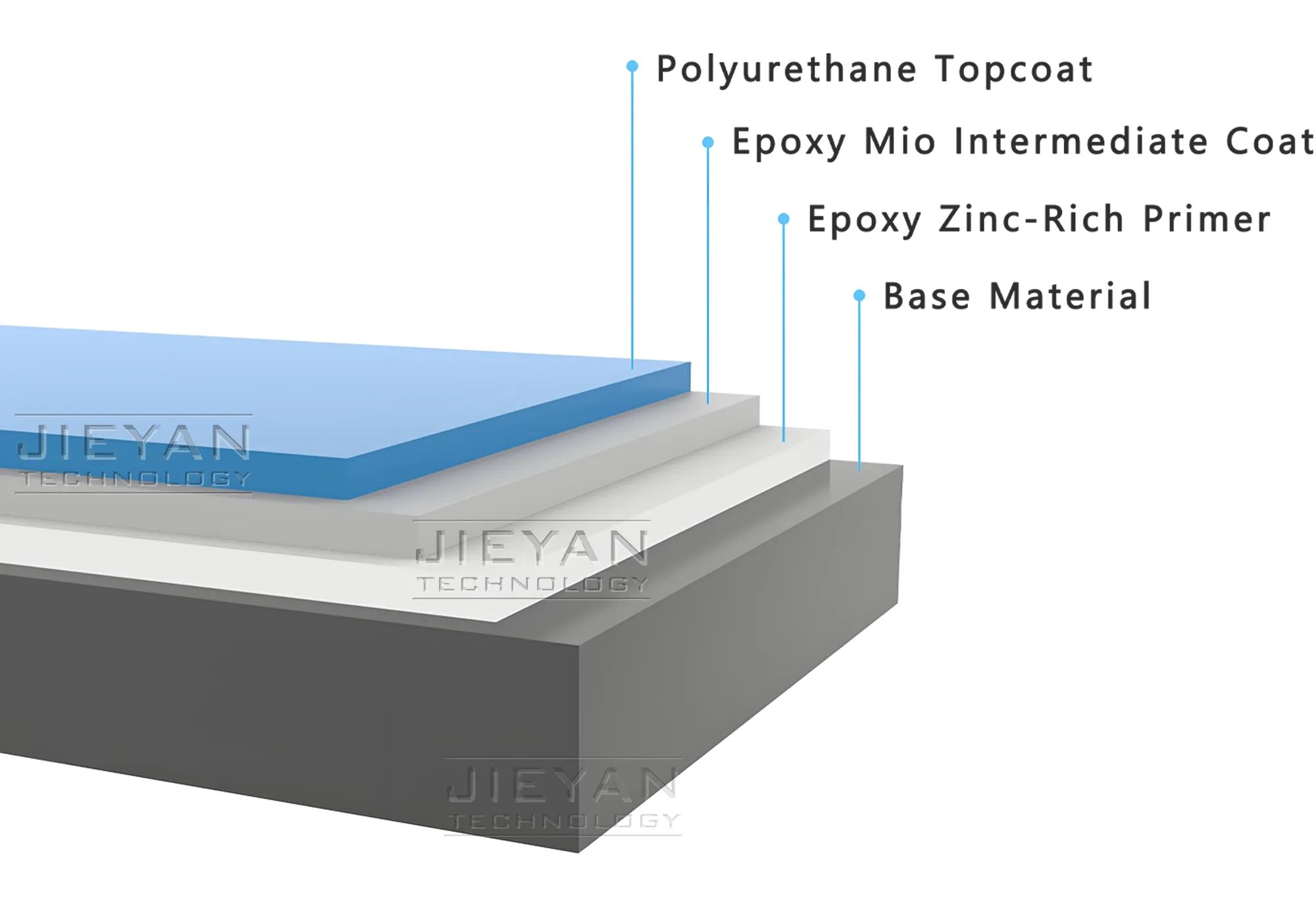

Professional-Grade Coating

SA2.5 blasting preparation combined with a three-layer coating system (zinc-rich epoxy, micaceous iron oxide, polyurethane) delivers ≥200μm of superior corrosion protection.

Intelligent Control System

Featuring Schneider components with wireless remote and PLC+HMI interface, the system supports Ethernet connectivity for seamless plant integration.

Optional Accessories

Optional Trimming System

Optional Pivot Hopper

Optional External Dust Sleeve

Related Cases

Related products

Contact Us

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219

Submit Successfully!

We have received your message and will contact you soon.