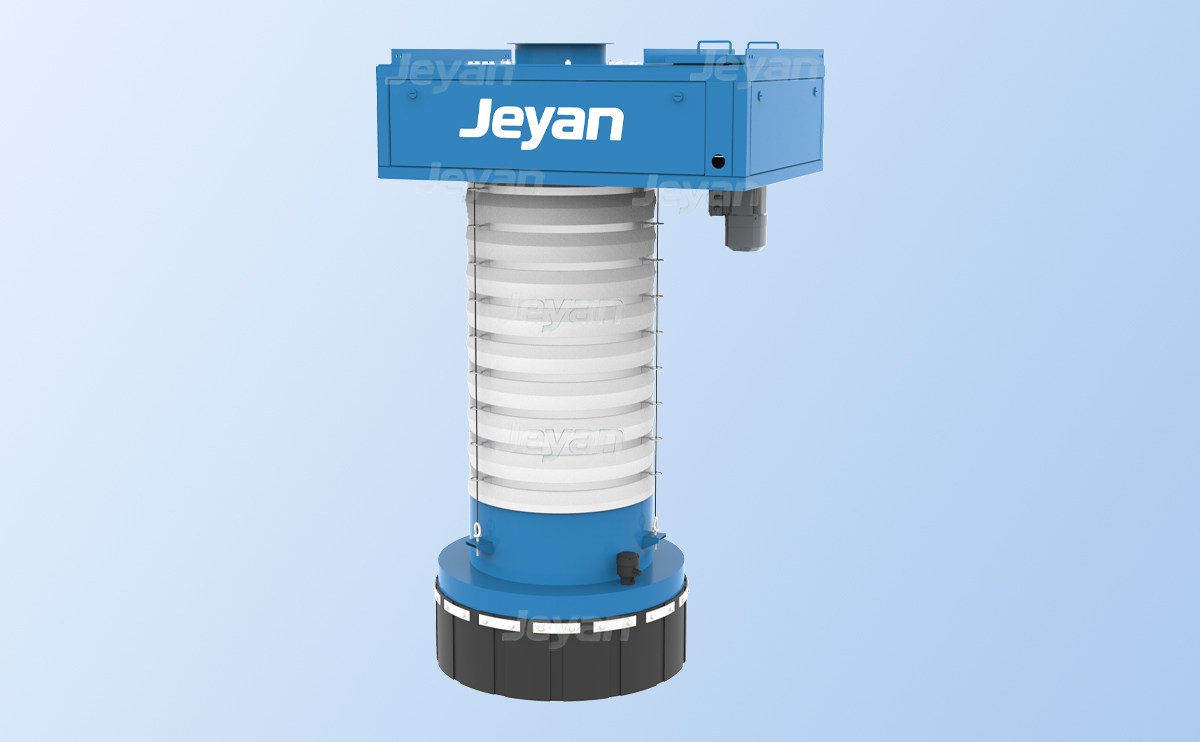

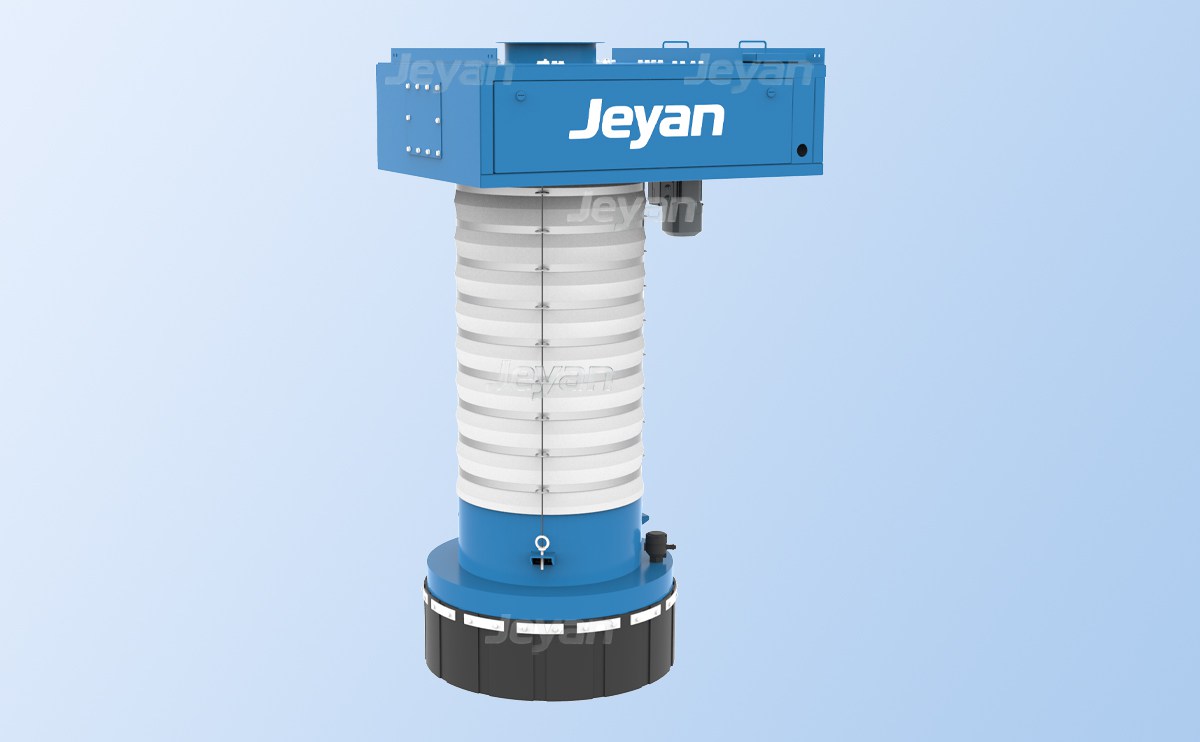

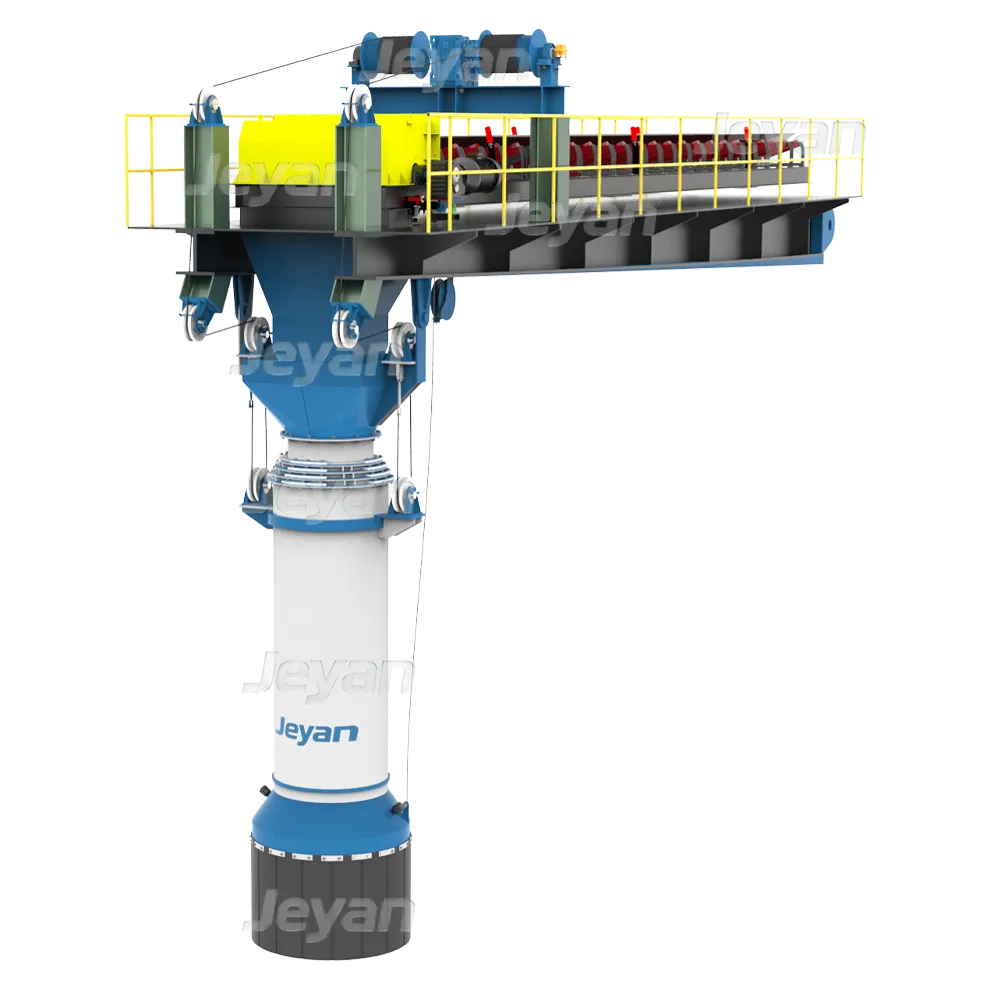

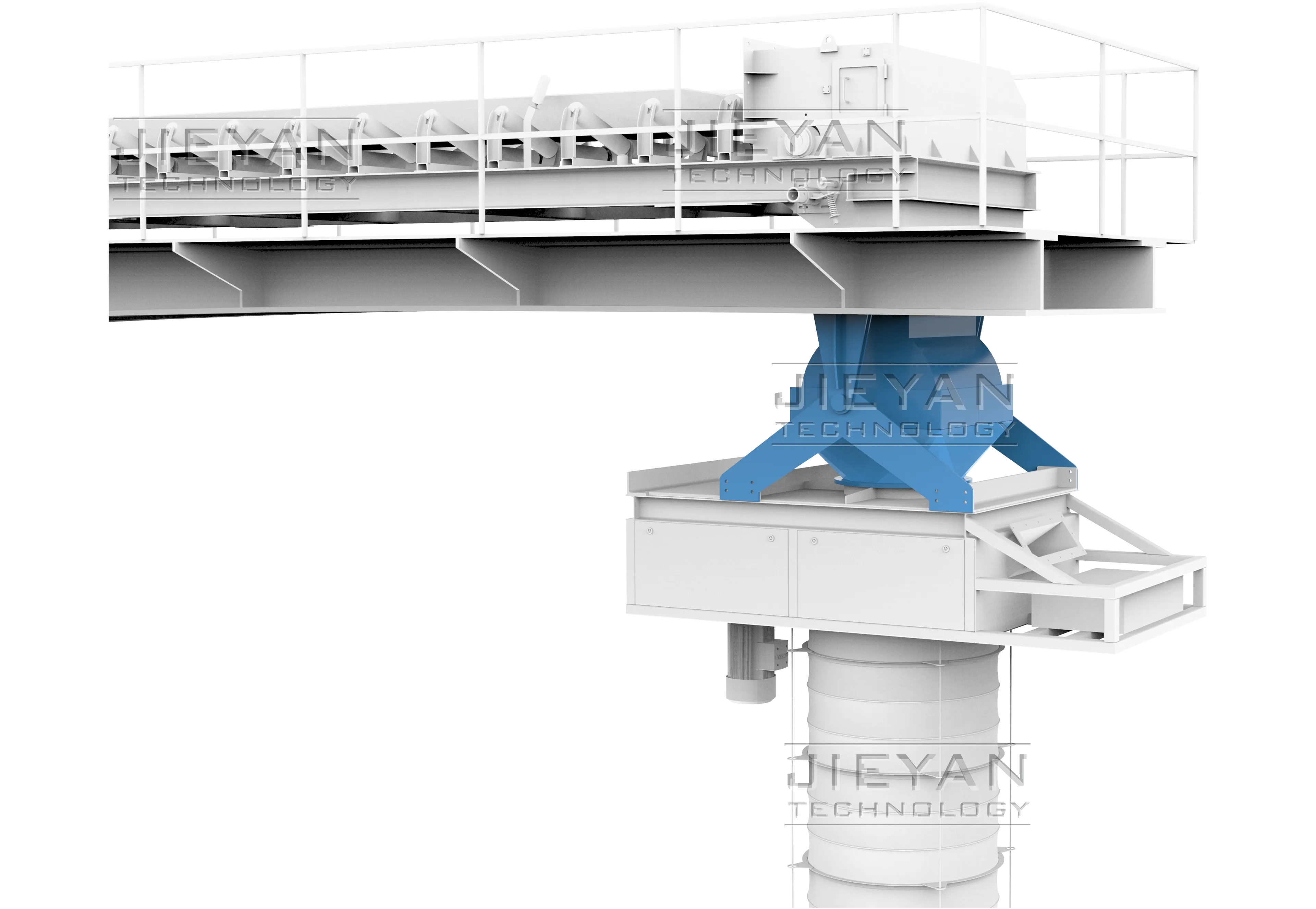

TC Stacking Loading Spouts

Stacking Loading Spouts (TC Series) are designed to load dry bulk materials from conveyors and other discharge points into open piles. These rugged heavy duty spouts are available in travel lengths from 3 meters up to 30 meters. Loading rates can vary up to 4600 m³/hour depending on product being loaded.

Truck loading

Port bulk loading

Mine yard

Carriage loading

Dry bulk material loading for open trucks and rail cars

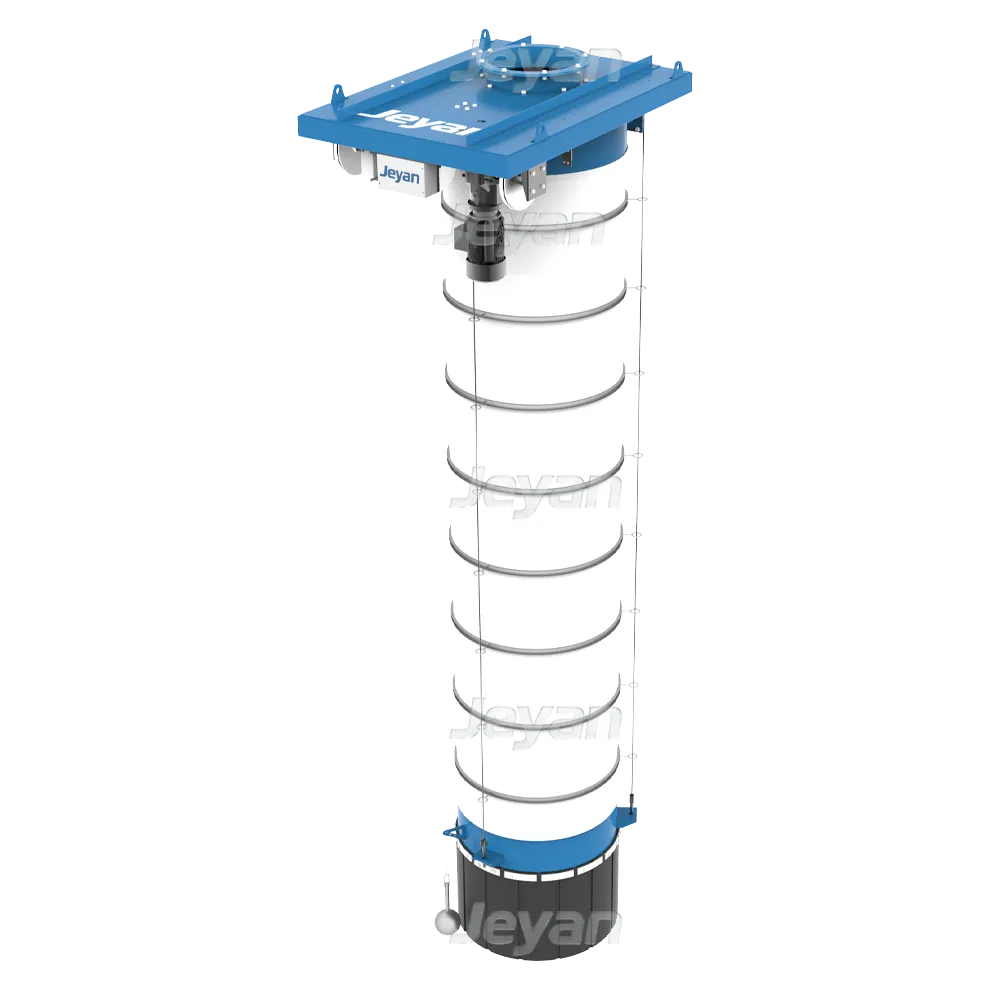

Structure and Principle

① Heavy-duty structure design to the harsh working conditions

② Three or four cable hoist system providing maximum spout stability

③ Integrated control cabinet with remote panel

④ Access doors to the drive components

⑤ Full up/down limit switch

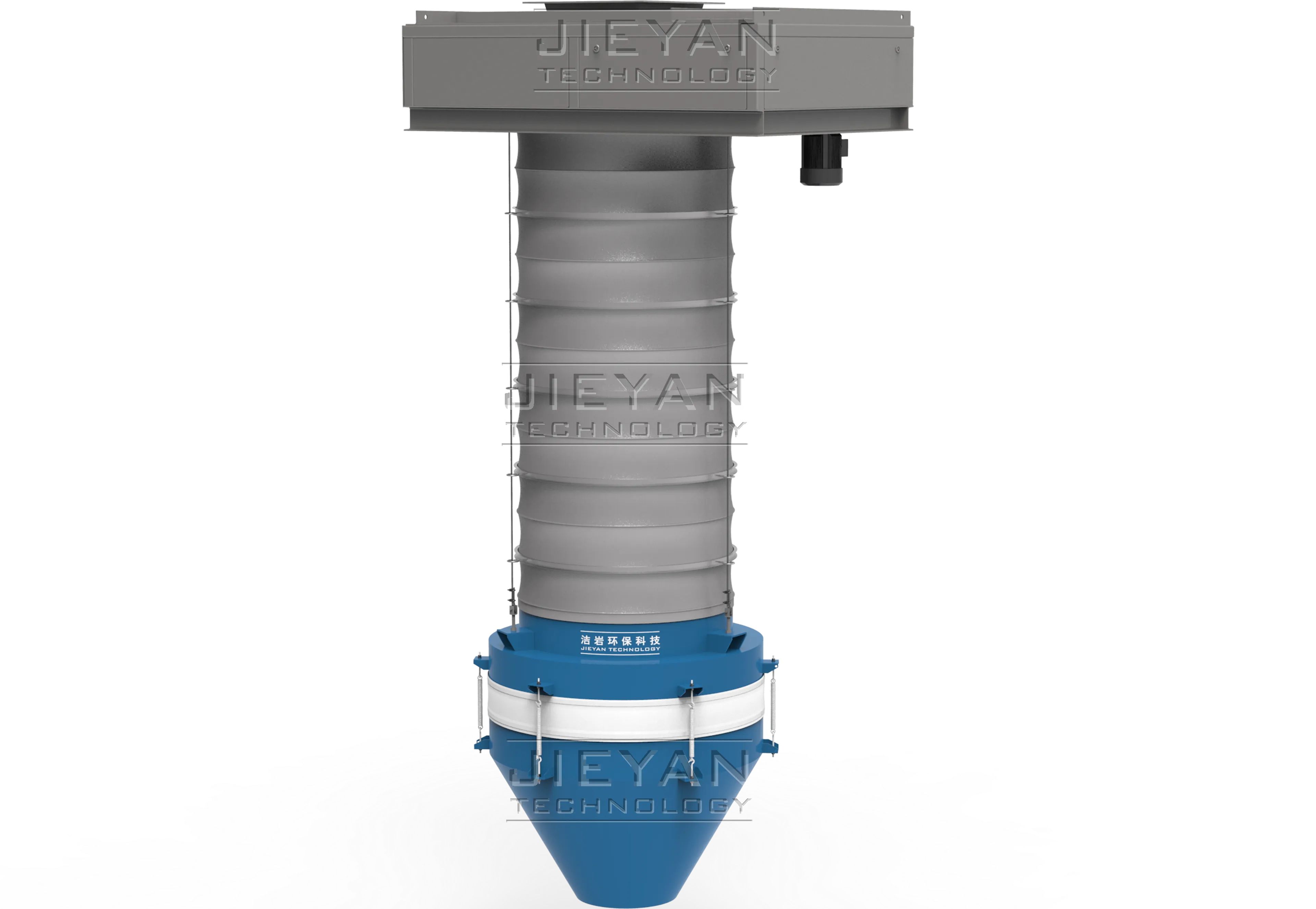

⑥ Inner cones materials option:

carbon steel

stainless steel(304.316)

abrasive resistant steel

⑦20 OZ. Polyester outer sleeve

⑧Flexible double layer rubber skirt

⑨Auto raise tilt probe

Technical Features

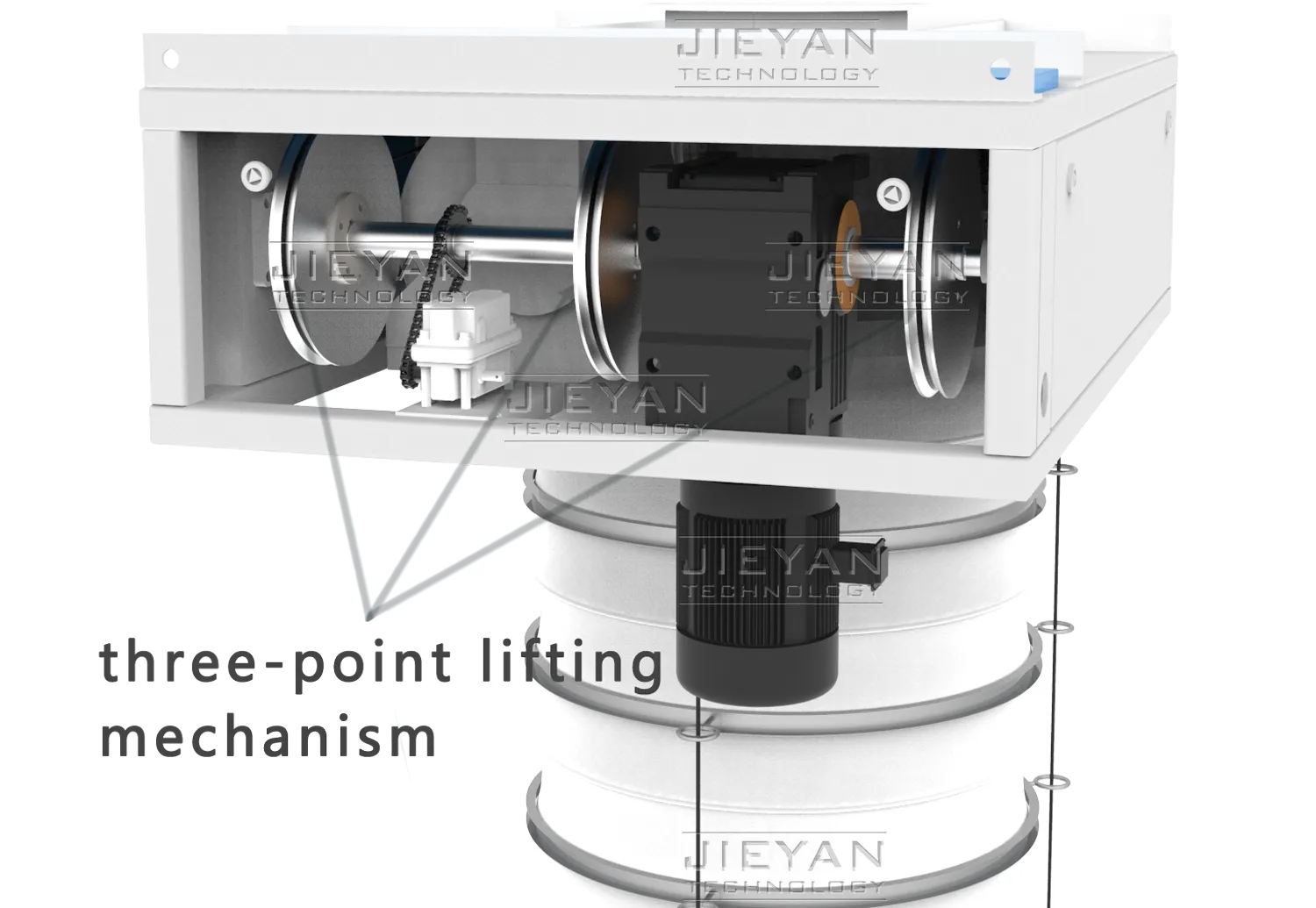

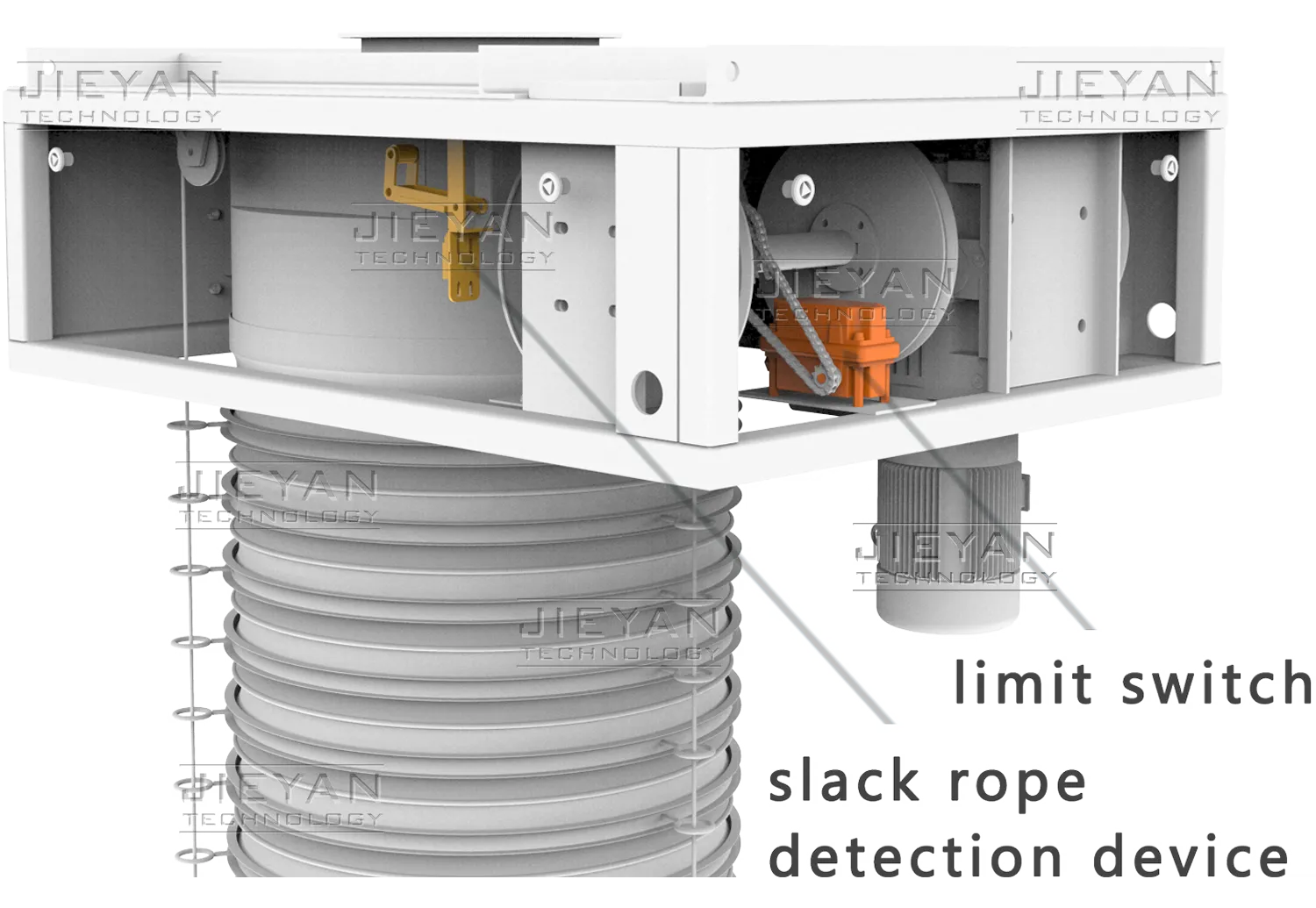

Triple-Rope Winch, Powerful Drive

Our triple-rope winch system ensures exceptional stability during operation with its three lifting points. Paired with a high-torque K-series gearbox delivering over 96% efficiency and superior overload capacity, it's engineered for the most demanding heavy-duty applications.

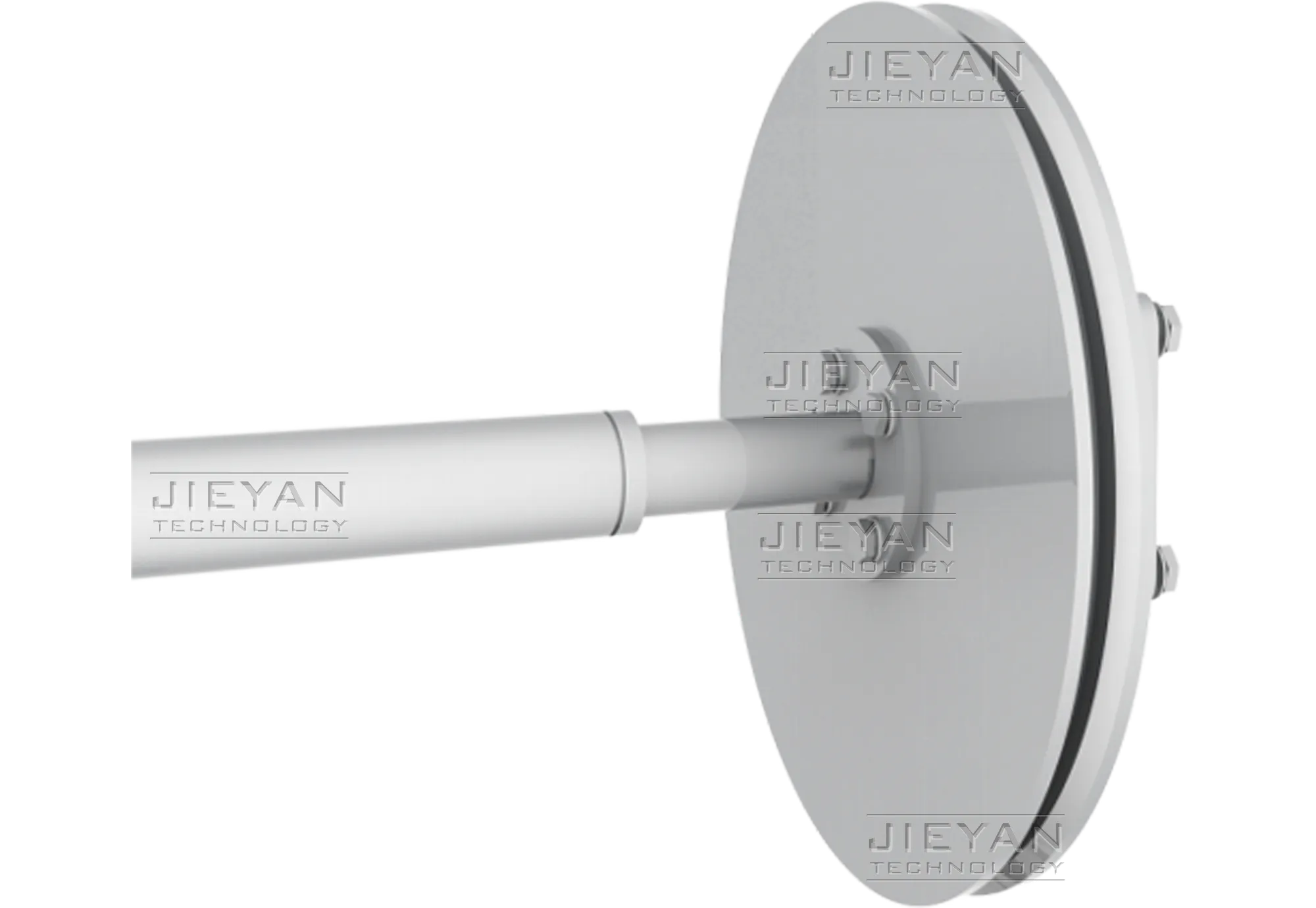

Reinforced Core Components

Precision-machined shafts and winches undergo specialized heat treatment for optimal surface finish that extends wire rope life. All components feature zinc plating for maximum wear and corrosion resistance.

Heavy-Duty Dust Sleeve

Constructed from durable materials like polyester, PVC or Hypalon with 1.0mm+ thickness, the sleeve features internal steel reinforcement for structural integrity and low-friction operation that protects wire ropes.

Configurable Wear Liners

Standard Q355B construction with optional NM abrasion-resistant steel or stainless steel. Available ceramic, UPE, or hard-faced linings provide maximum protection in severe wear environments.

Smart Limit Protection

Adjustable limit switches with spare settings and standard slack rope detection prevent over-travel and derailment, ensuring safe operation in all conditions.

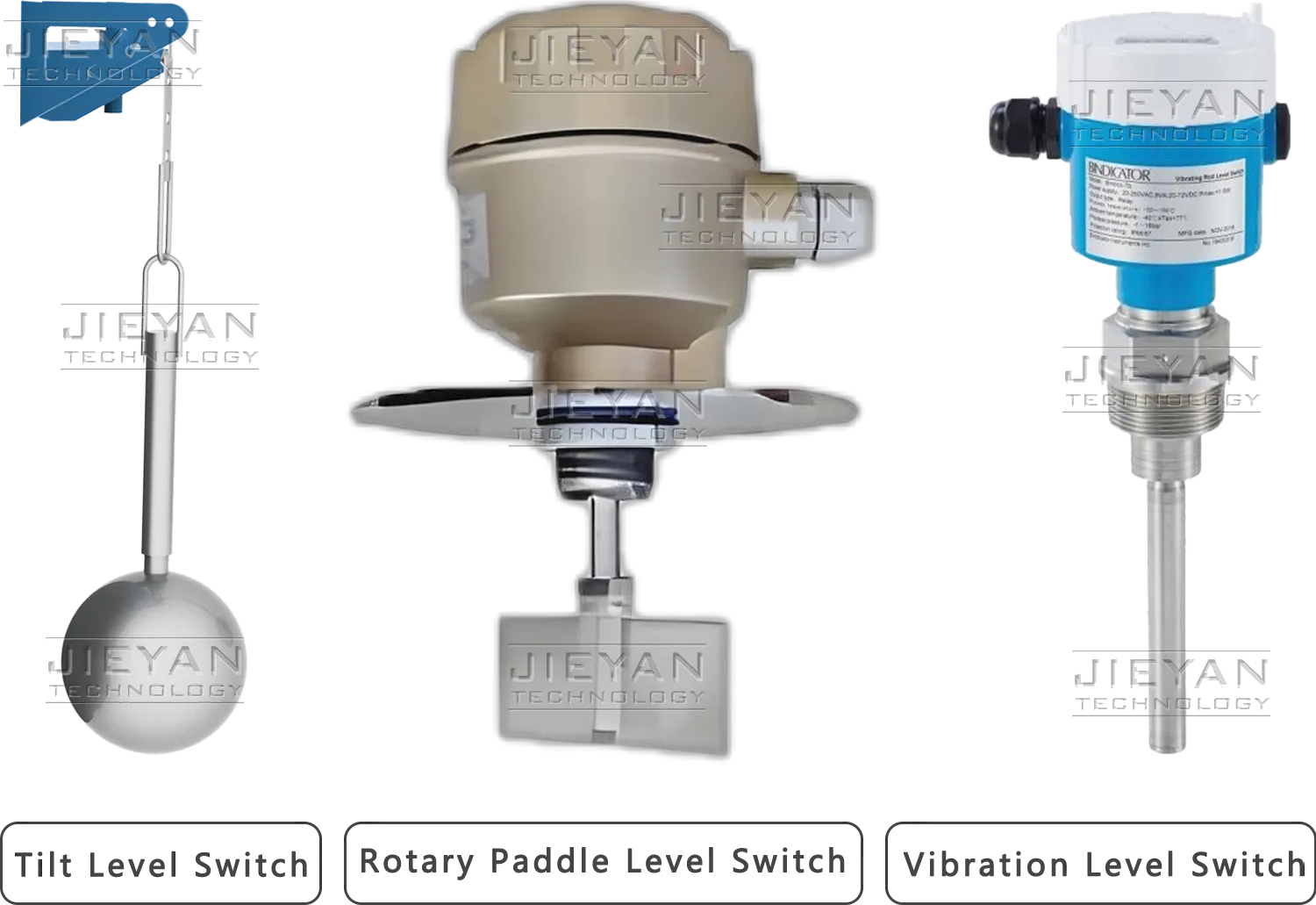

Flexible Level Monitoring

Multiple level switch options including rotary paddle, vibration and differential pressure types provide accurate monitoring for various materials and installation needs.

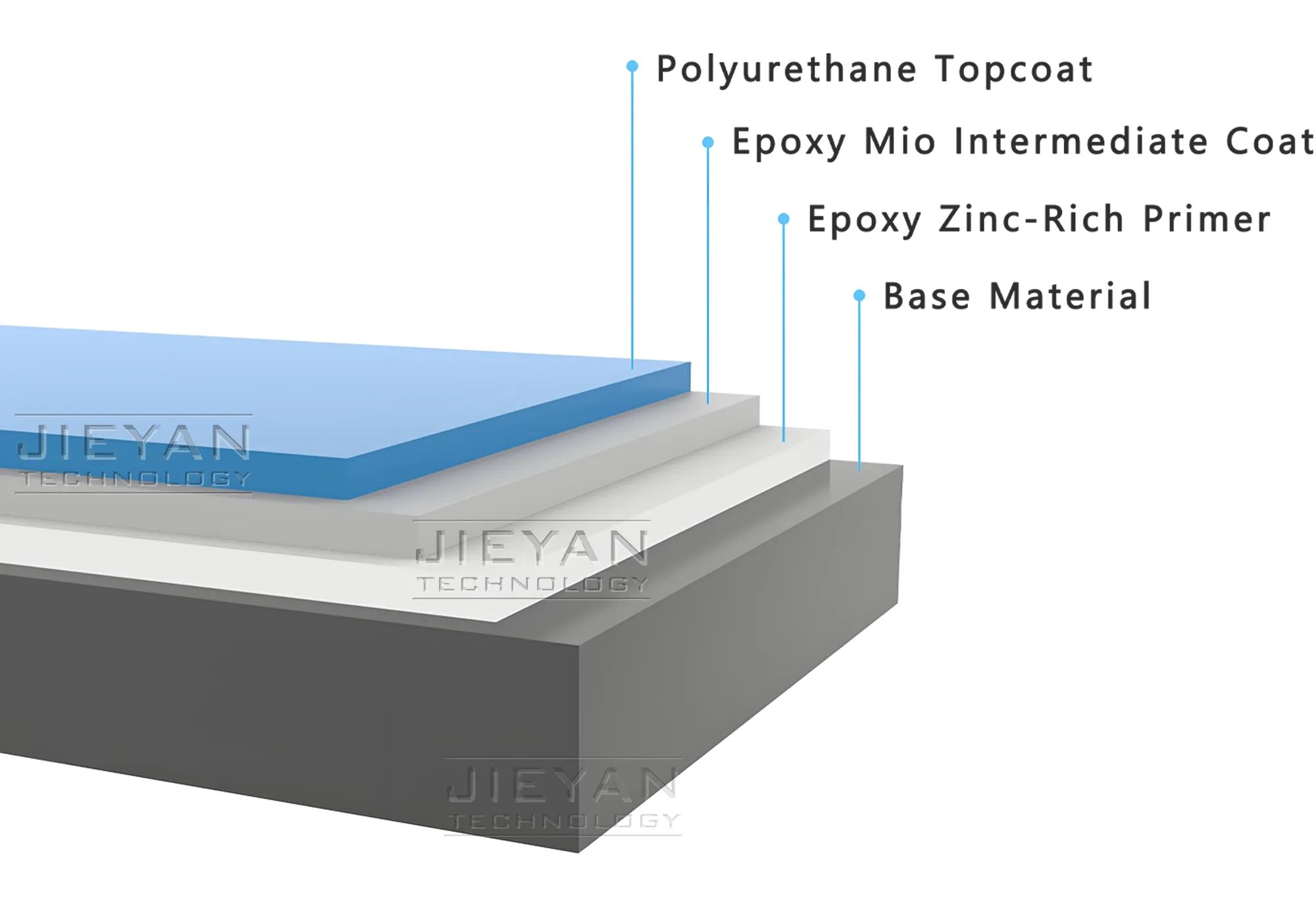

Professional Coating System

SA2.5 blasting preparation combined with a three-layer coating system (zinc-rich epoxy, micaceous iron oxide, polyurethane) delivers ≥200μm of superior corrosion protection.

Intelligent Control System

Featuring Schneider components with wireless remote and PLC+HMI interface, the system supports Ethernet connectivity for seamless integration into plant control networks.

Custom Engineering Solutions

We customize inlets, outlets, lifting points and discharge spouts to your specifications, ensuring perfect integration with your existing operations and workflow.

Optional Accessories

Optional Pivot Hopper

Optional Dust Suppression Hopper

Related Cases

Contact Us

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219

Submit Successfully!

We have received your message and will contact you soon.