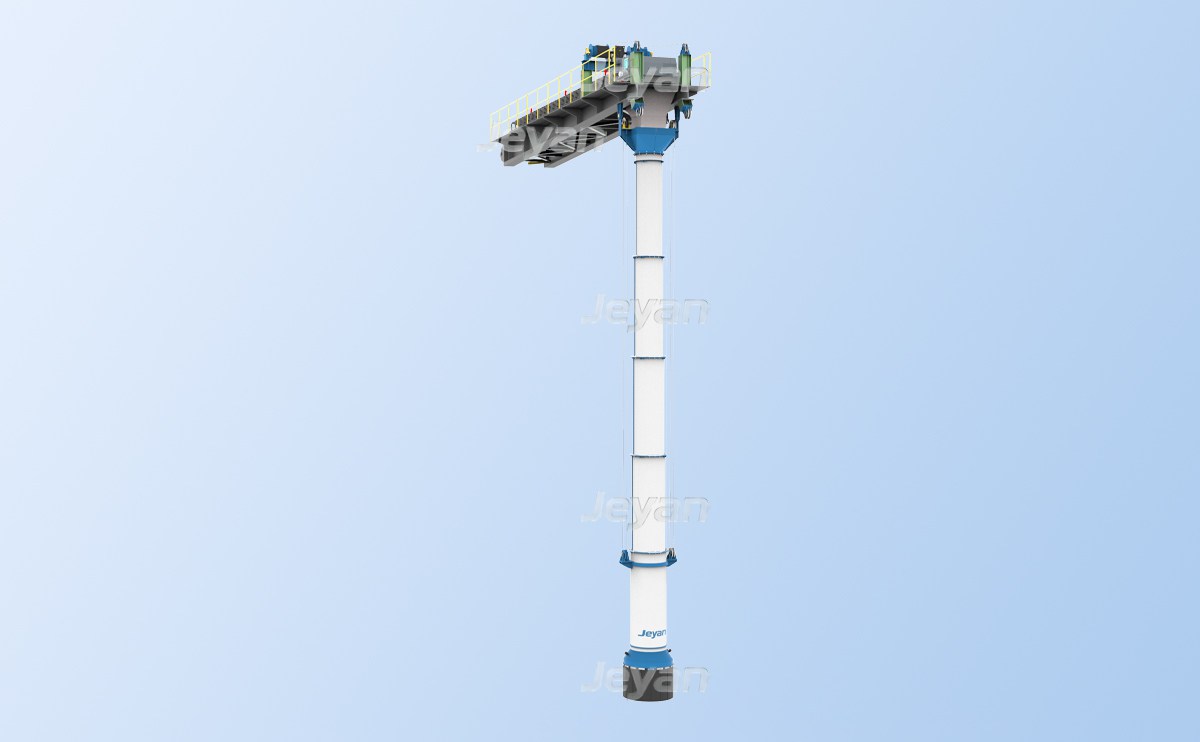

TL Ship Loader

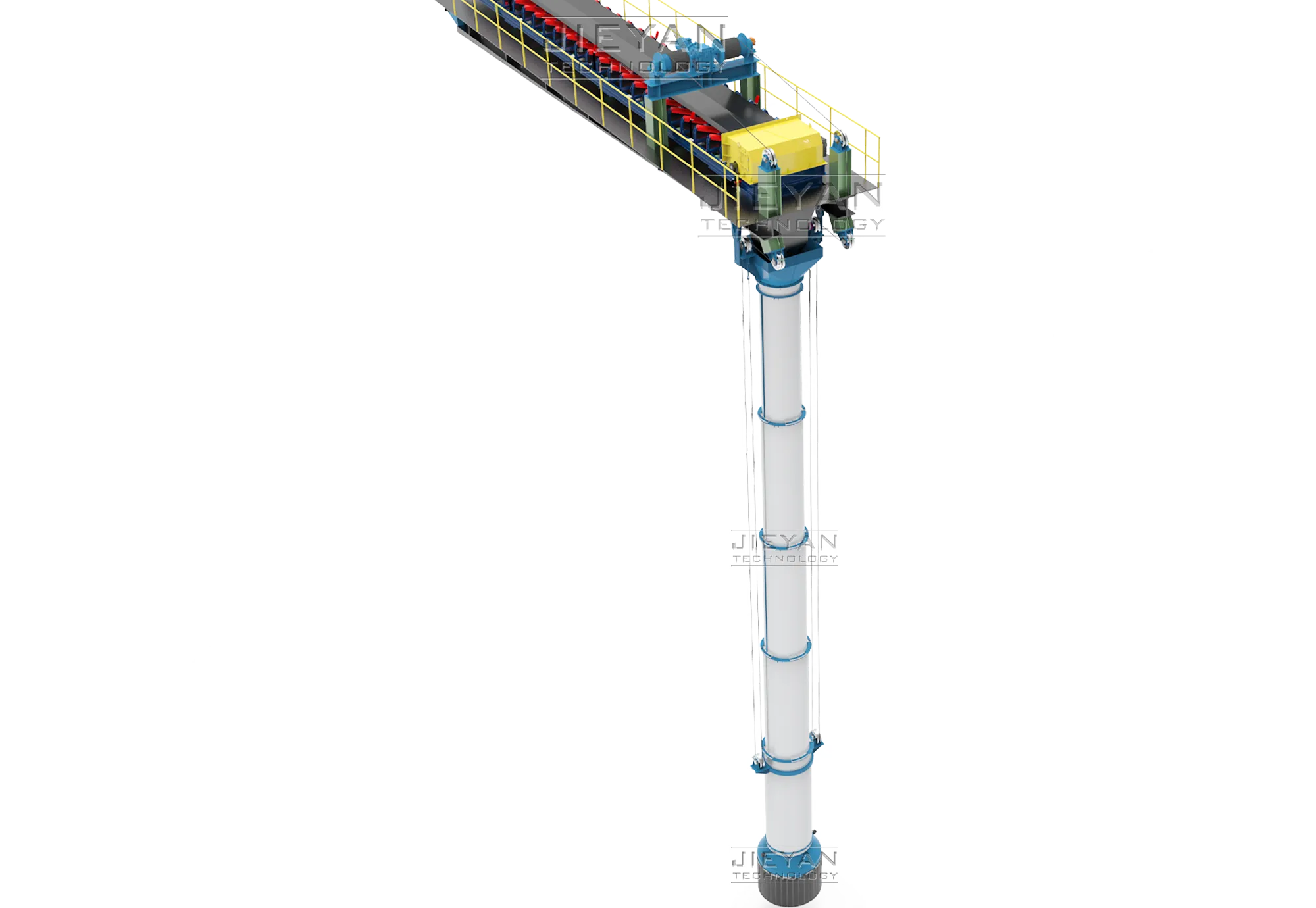

ship loader (TL Series) are designed to load dry bulk materials from conveyors and other discharge points into ships. These rugged heavy-duty spouts are available in travel lengths from 3 meters up to 30 meters. Loading rates can vary up to 6000 m³/hour depending on product being loaded.

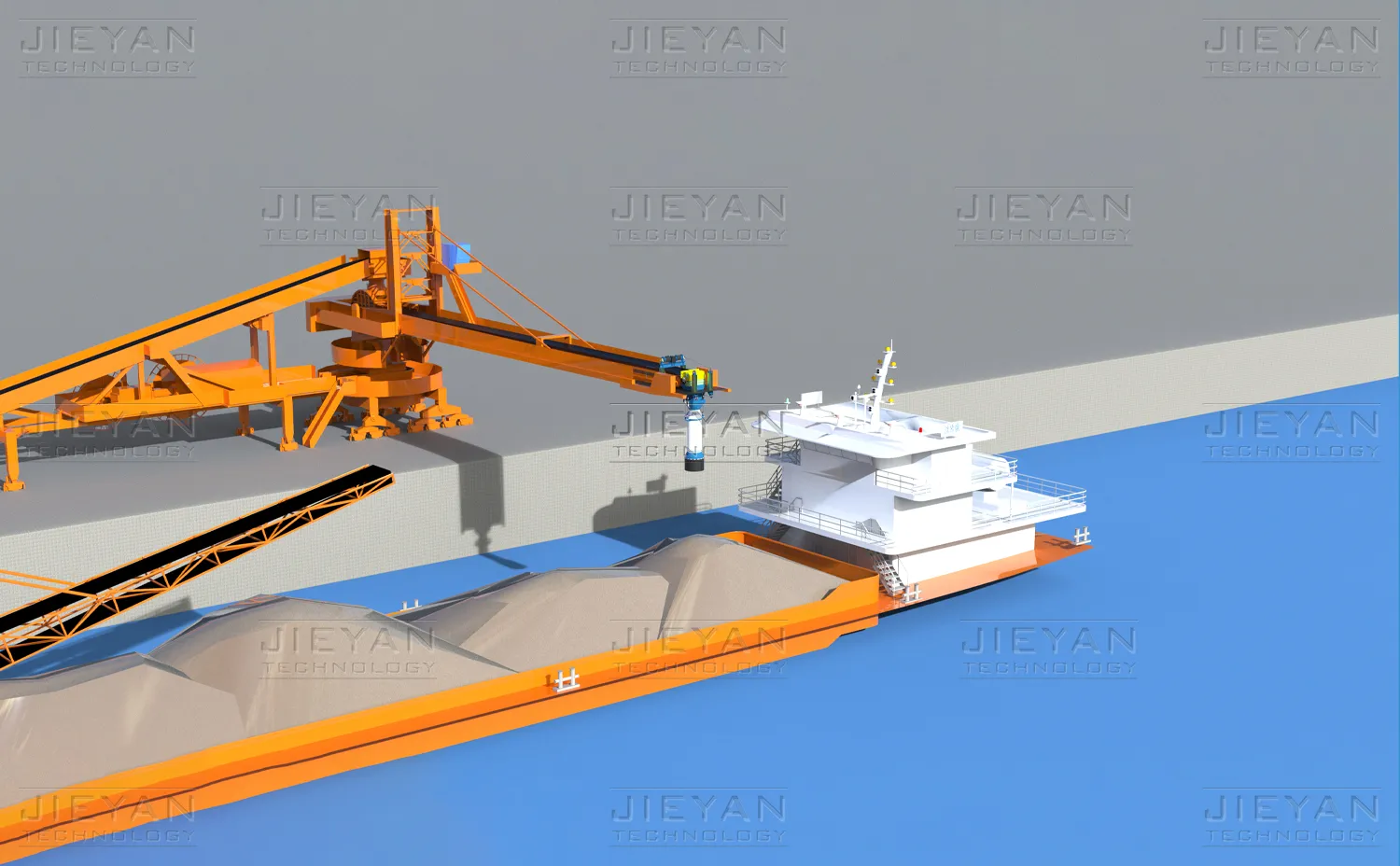

Port loading

Ore loading

Mine yard

Mineral powder loading

Port bulk loading

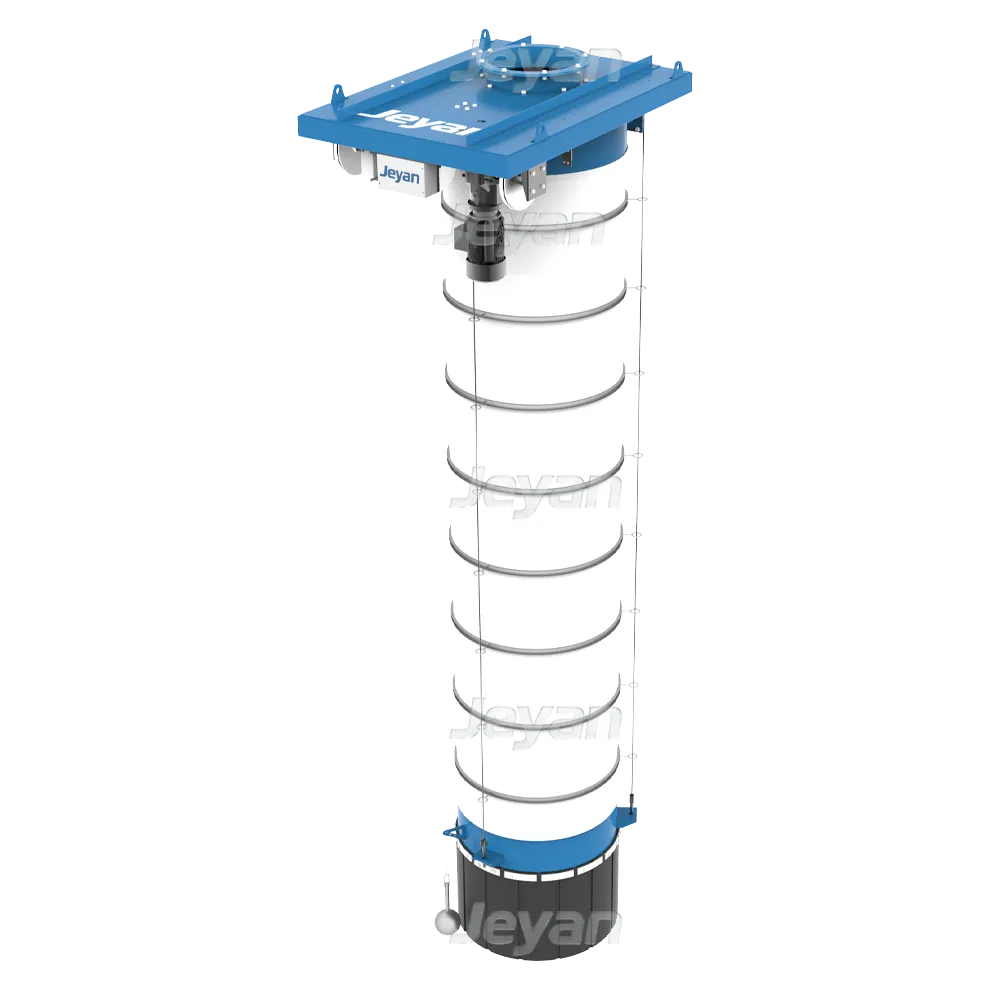

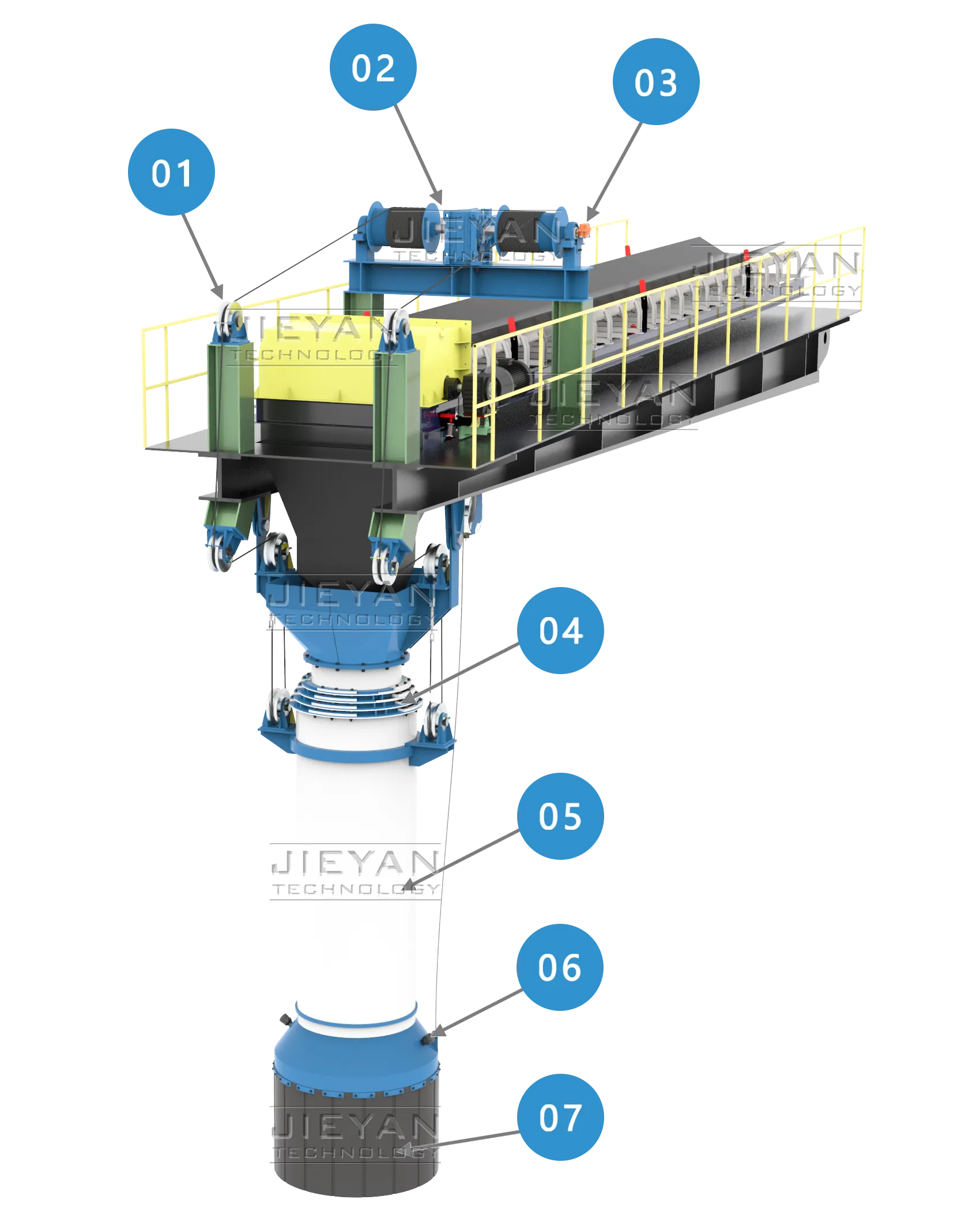

Structure and Principle

① Sheave

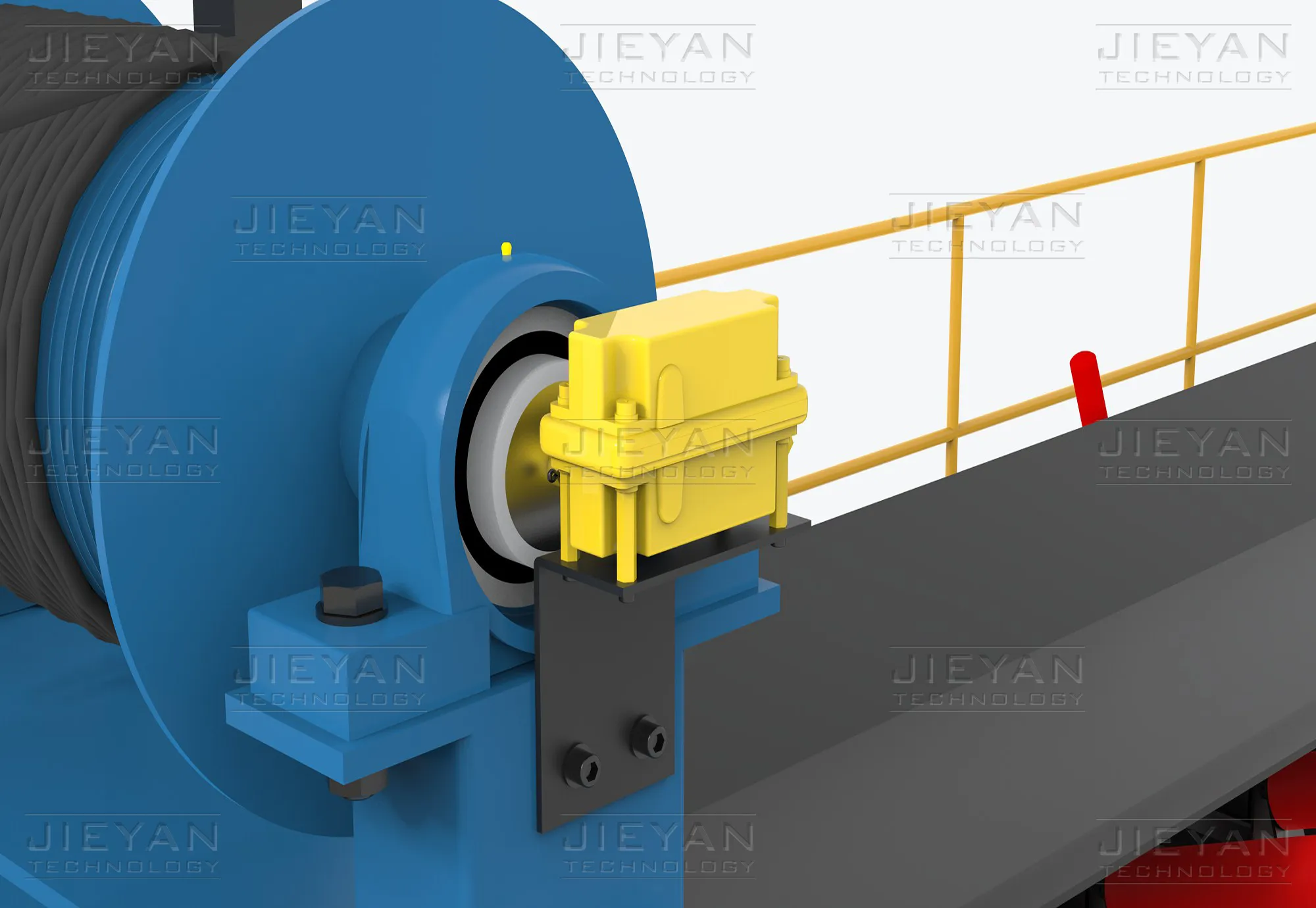

② Winch device

③ Rotary Limit Switch

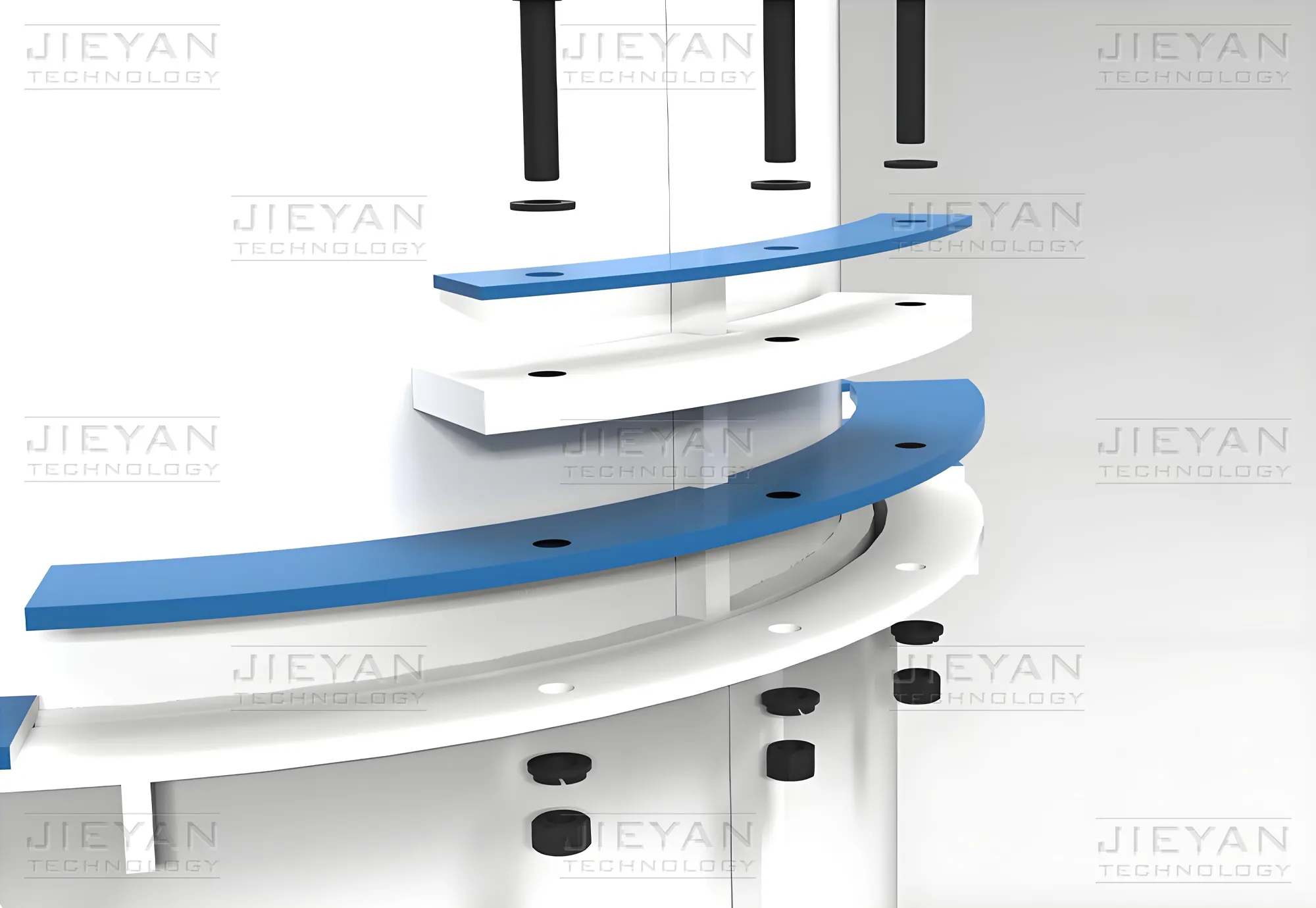

④ Tube Guide Ring

⑤ Wear-resistant Tube

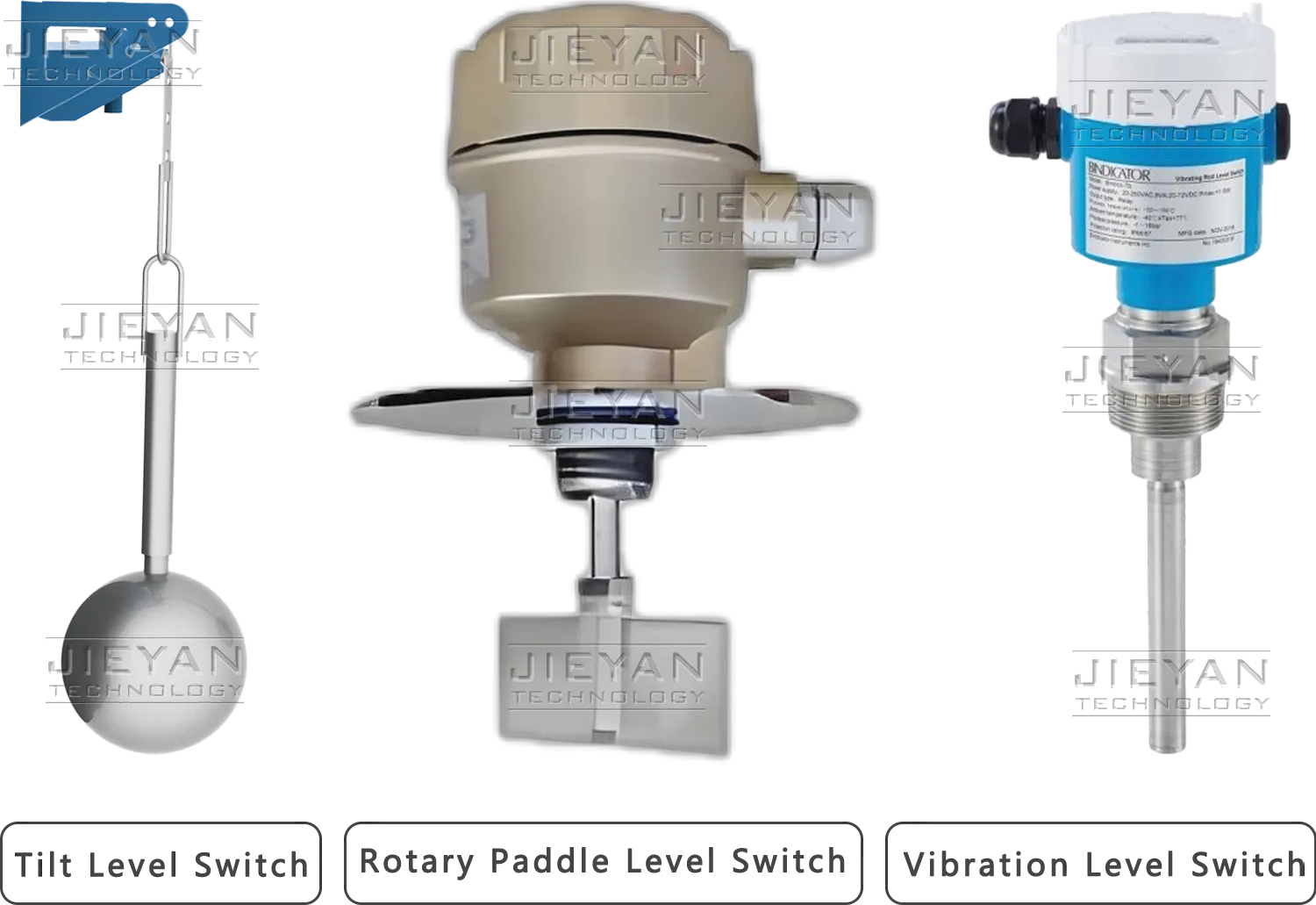

⑥ Material Level Switch

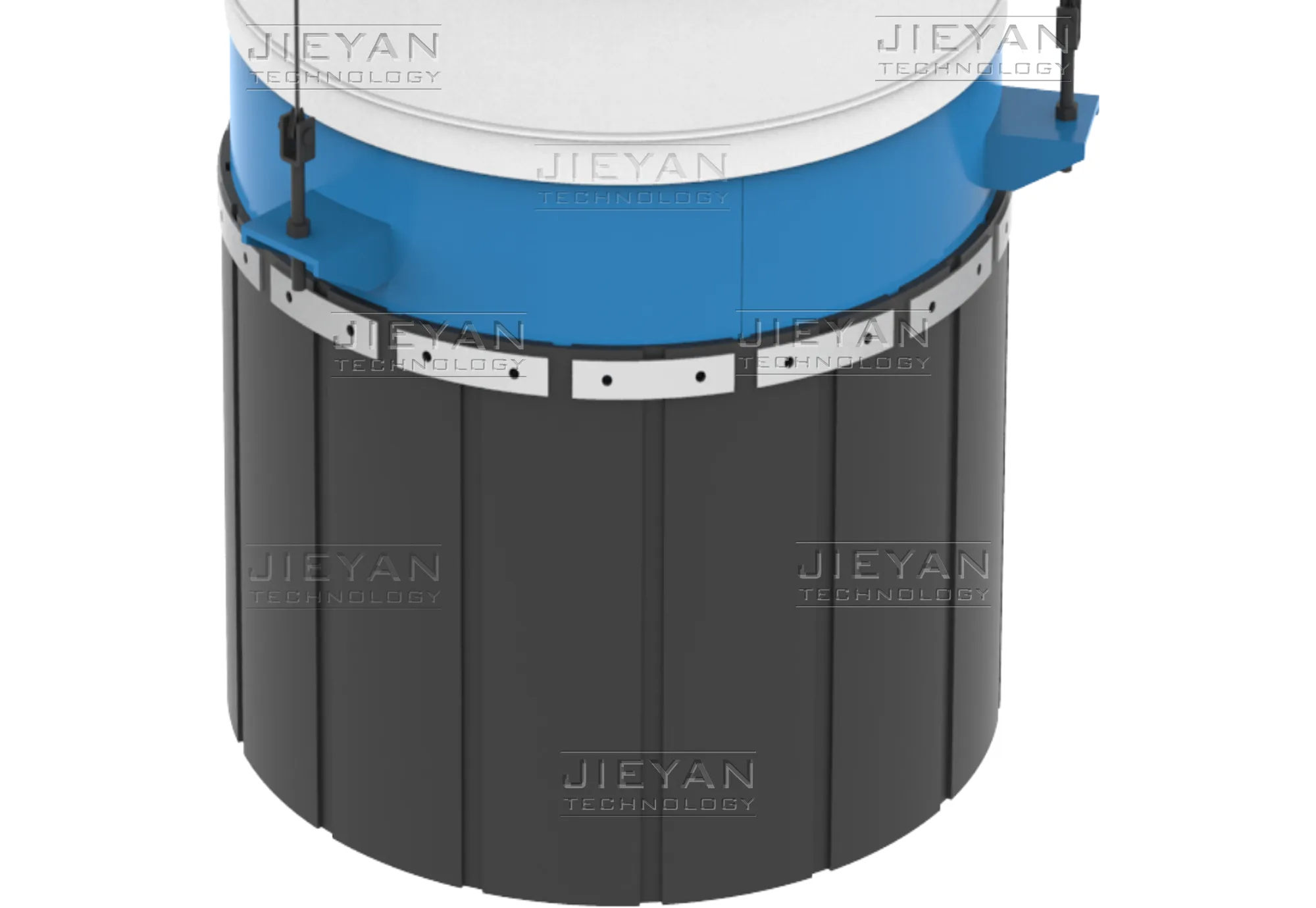

⑦ Rubber Skirt

Technical Features

High Capacity & Extended Reach

With a handling capacity of 6000m³/h and maximum extension of 30 meters, this system delivers the performance needed for most ship loading and stockpiling operations.

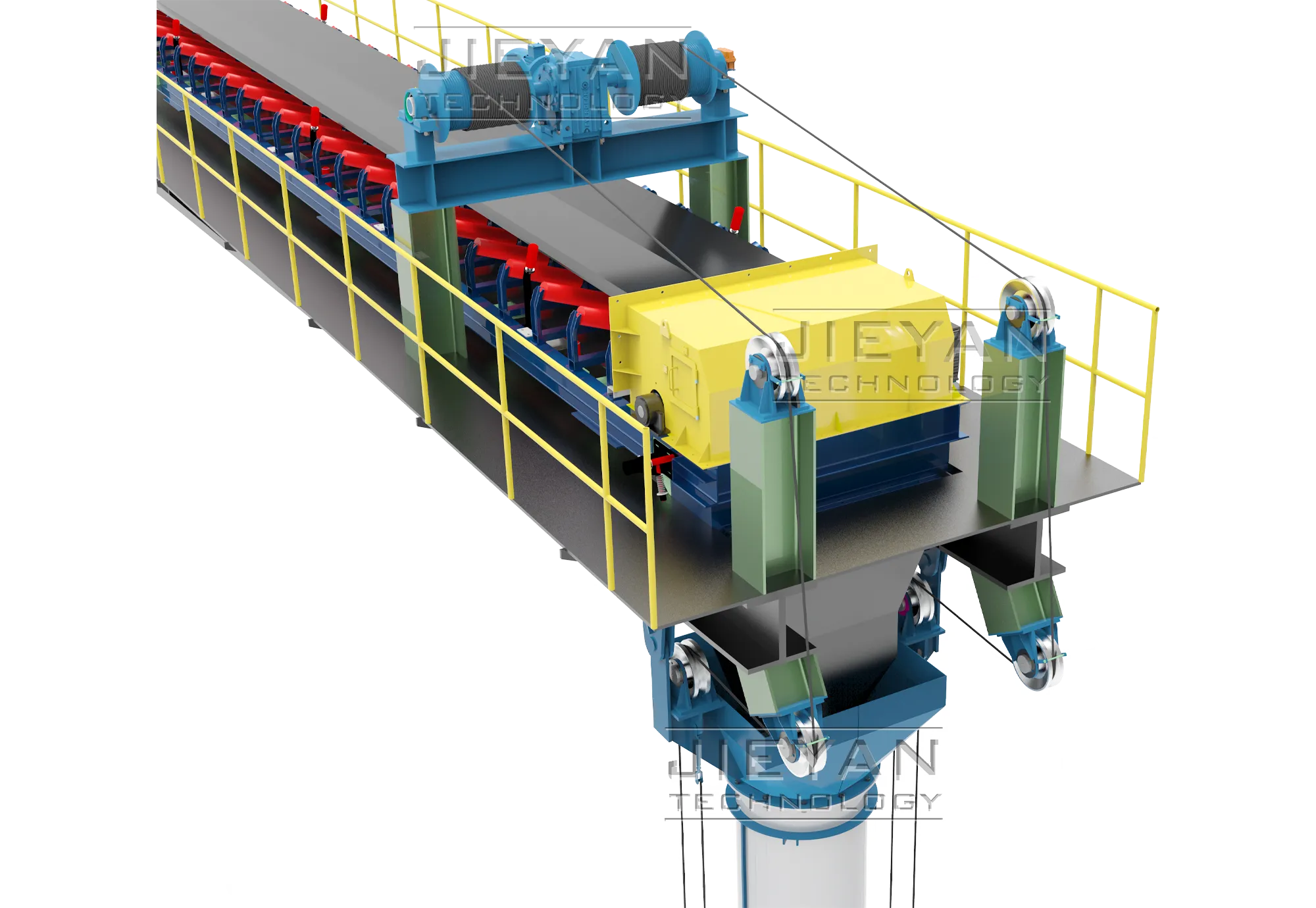

Modular Design for Easy Maintenance

The separate lifting mechanism and spout body allow independent installation of the hoist on the conveyor frame, creating ample workspace that simplifies maintenance access and procedures.

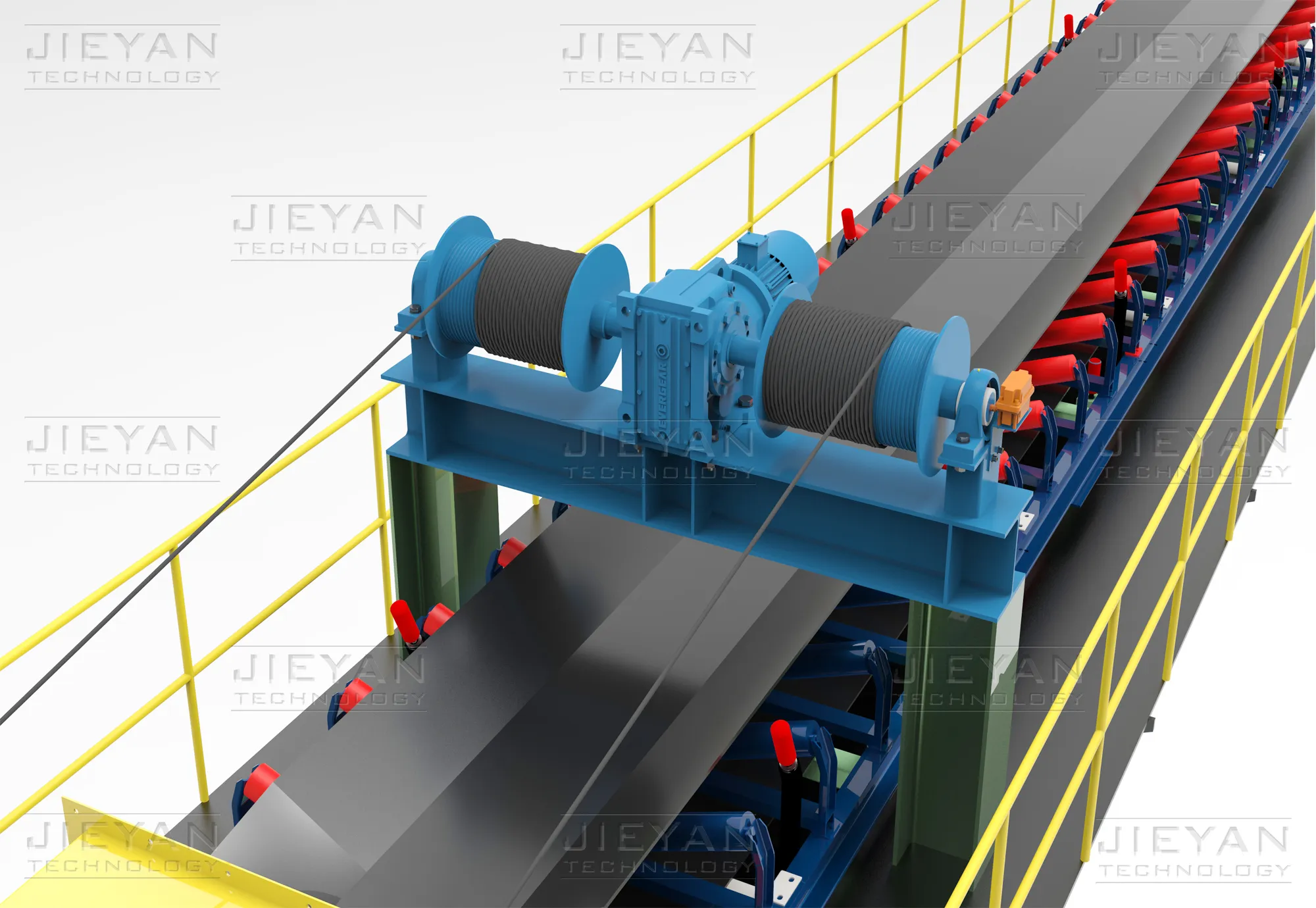

Grooved Drum & Efficient Drive

The grooved drum design prevents rope slippage and ensures smooth operation while reducing wear. Paired with a K-series gearbox delivering over 96% efficiency and high overload capacity, it's engineered for heavy-duty applications.

Modular Spout Construction

Featuring split clamping flanges for easy section replacement and UHMWPE guide rings that provide wear resistance and self-lubrication for smooth telescoping action.

Configurable Wear Protection

Standard Q355B construction with optional NM abrasion-resistant steel, stainless steel, or specialized linings including ceramic, UPE and tungsten carbide hardfacing for extreme wear conditions.

Smart Safety Systems

Programmable limit switches with backup settings and standard slack rope detection prevent overtravel and derailment for failsafe operation.

Flexible Level Monitoring

Multiple level switch options including tilt, rotary paddle and vibration types provide accurate monitoring for various materials and installation requirements.

Double-Layer Rubber Skirtl

Reinforced rubber skirt creates a tight seal with container outlets, effectively containing dust to meet environmental standards.

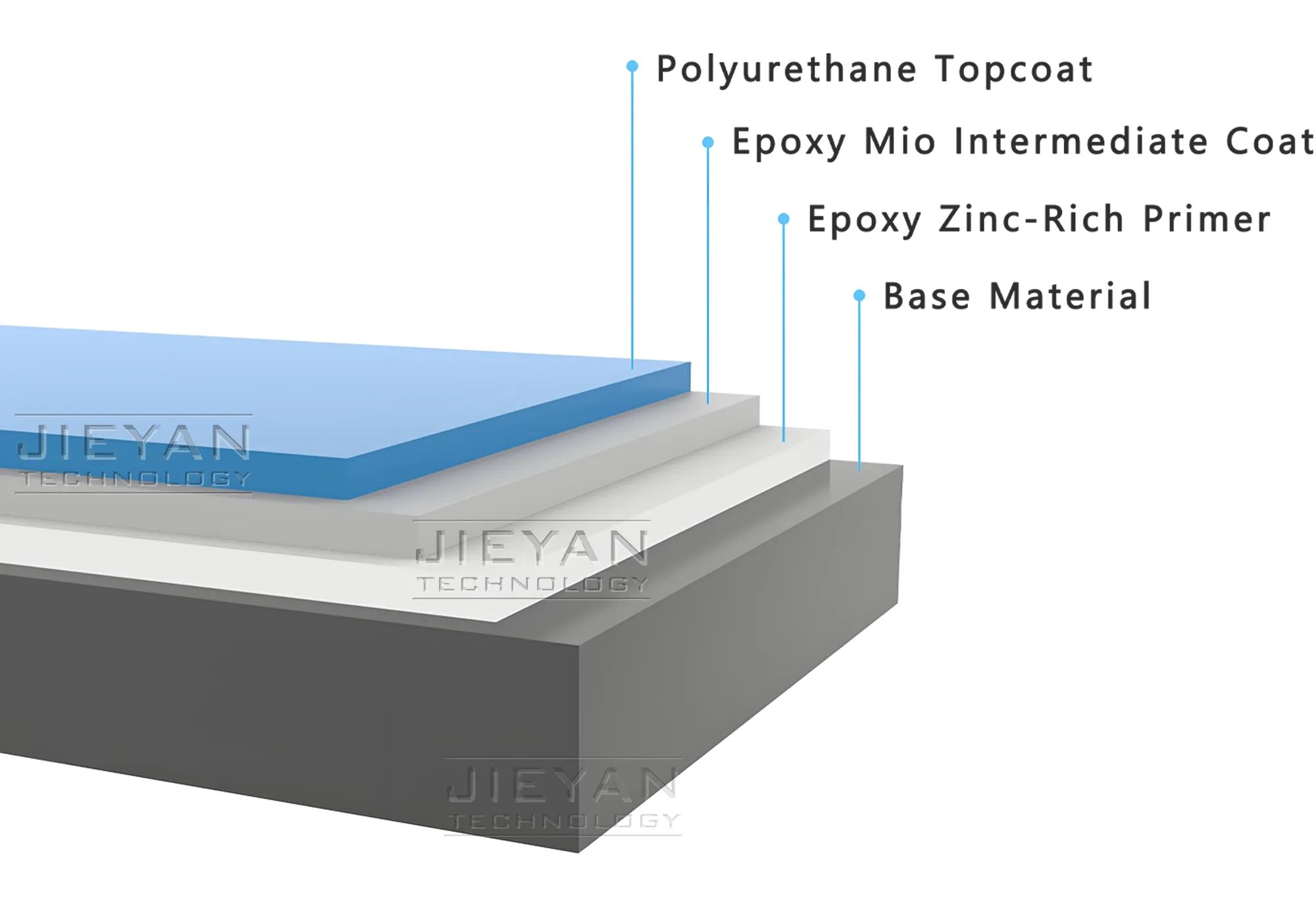

Professional-Grade Coating

SA2.5 blasting preparation combined with a three-layer coating system (zinc-rich epoxy, micaceous iron oxide, polyurethane) delivers ≥200μm of superior corrosion protection.

Intelligent Control System

Featuring Schneider components with wireless remote and PLC+HMI interface, the system supports Ethernet connectivity for seamless plant integration.

Related Cases

Related products

Contact Us

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219

Submit Successfully!

We have received your message and will contact you soon.