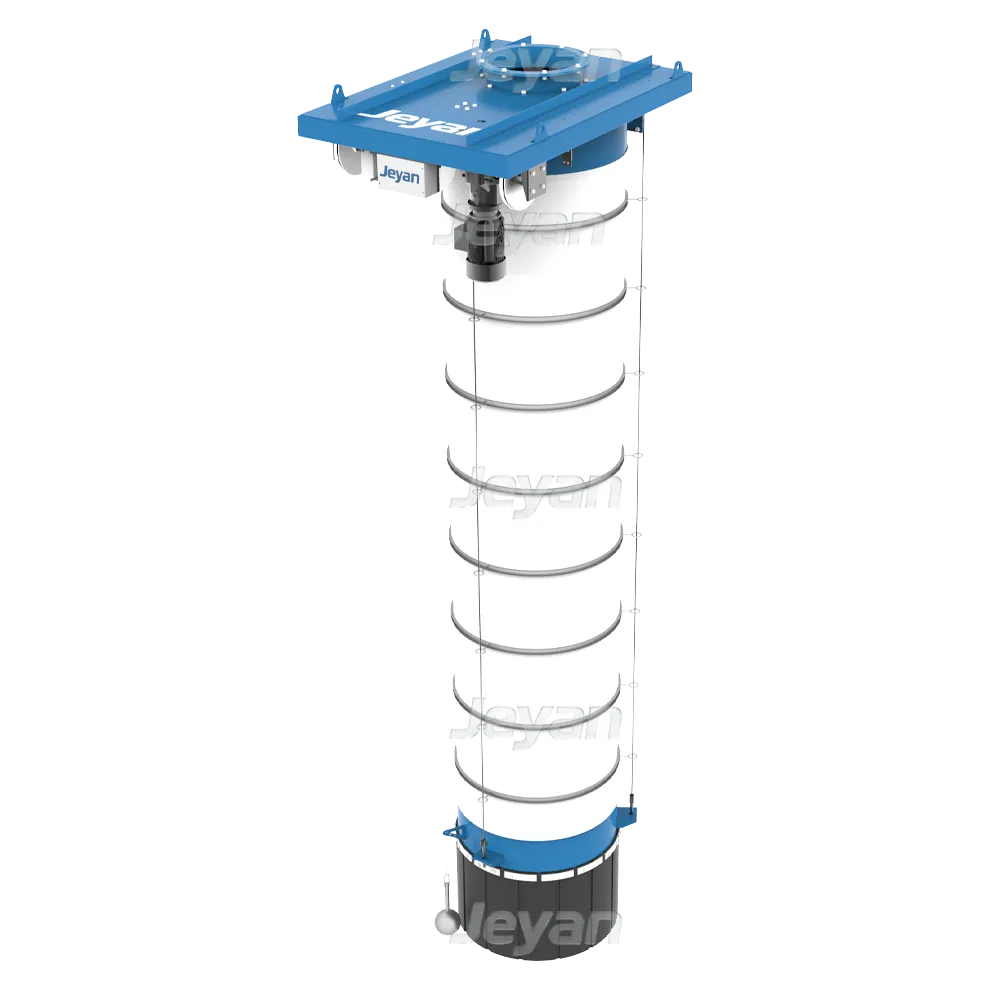

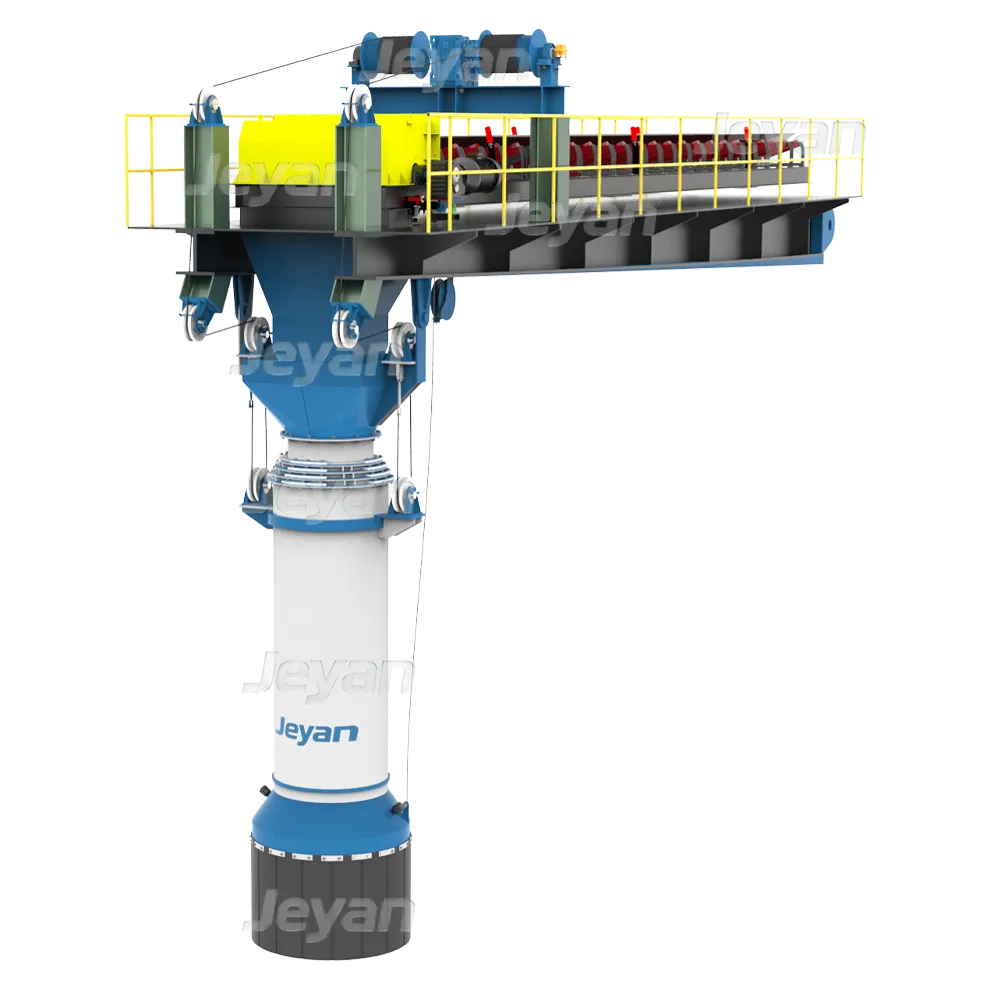

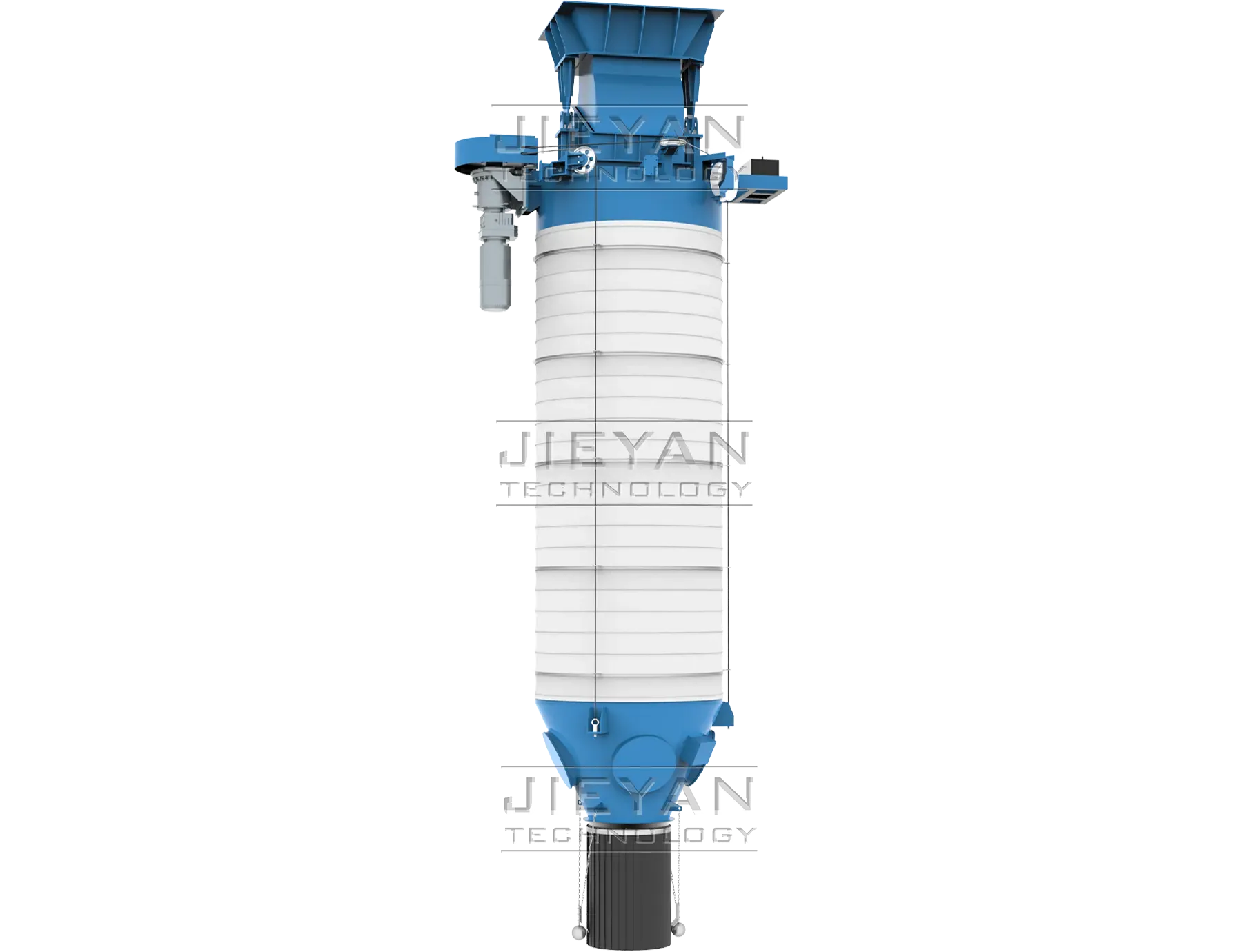

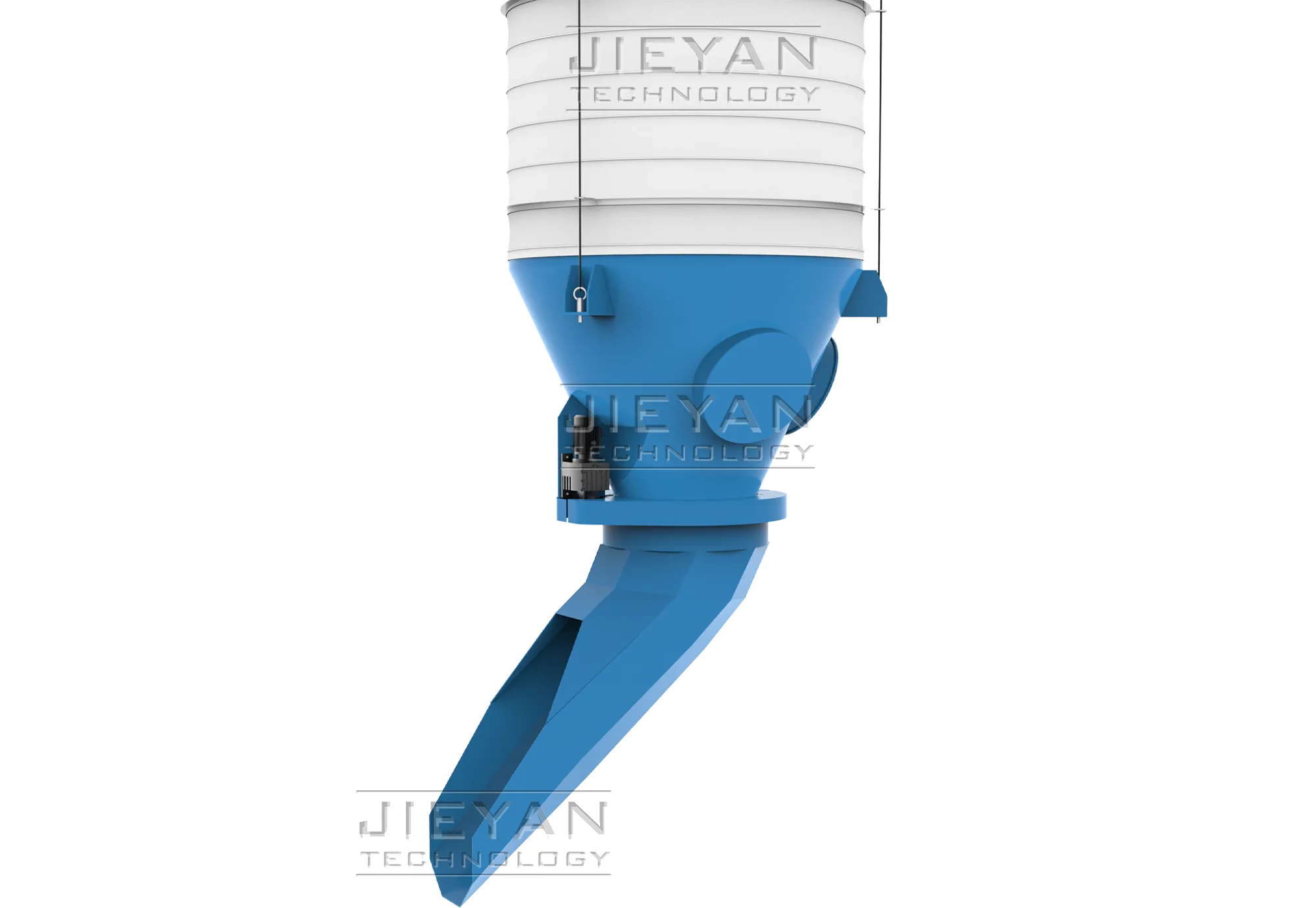

TH-series cascade loading spouts

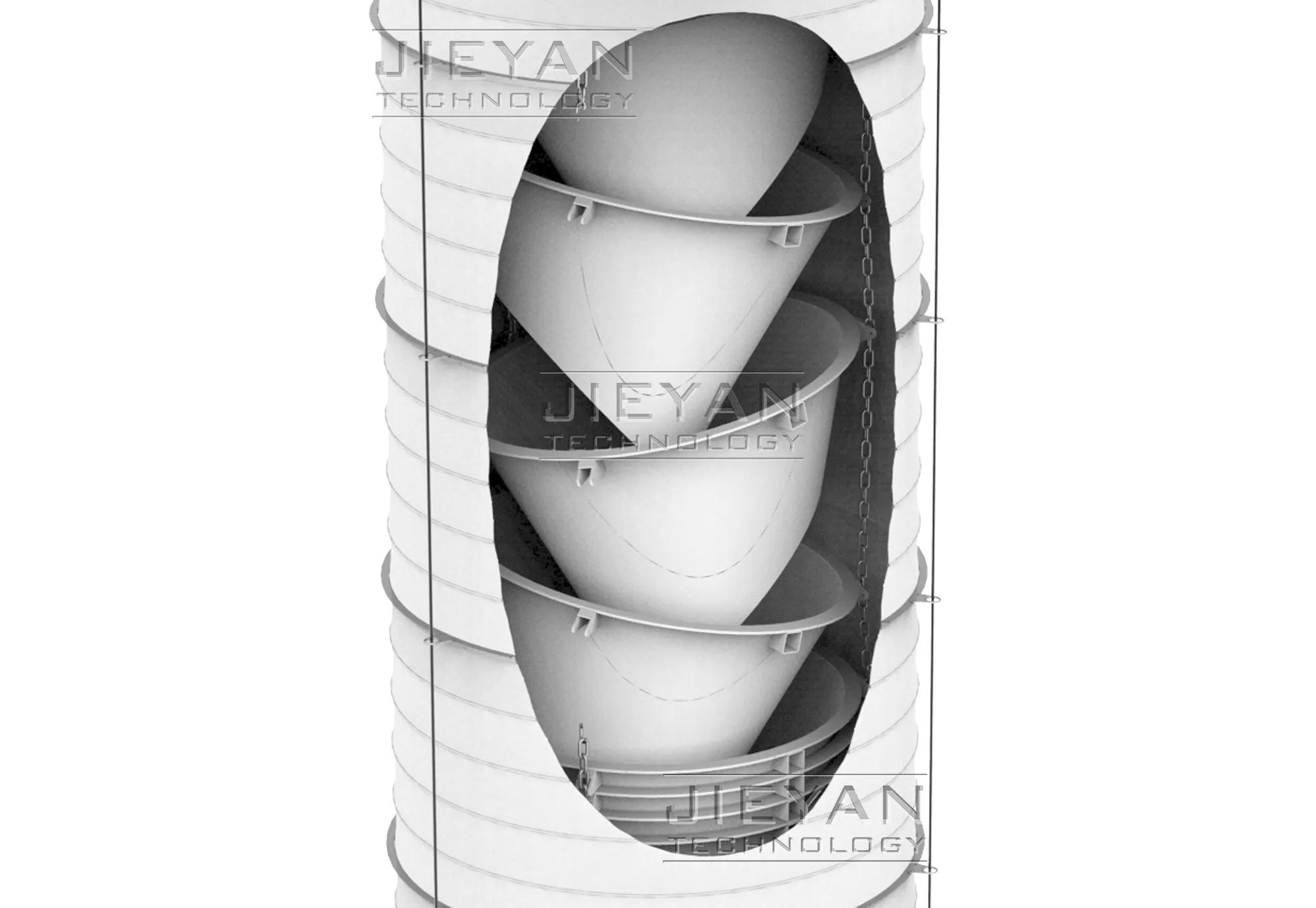

The TH series cascaded chute adopts a cascaded inclined conical tube flow-guiding structure, which reconstructs the material falling path. Under a controlled state, materials are smoothly guided through multi-stage conical tubes, maintaining a uniform speed during the entire falling process. Large and small particles remain uniformly mixed, isolating the interaction between air currents and materials and blocking dust diffusion. Materials reach the stockyard at a low speed, and the dust concentration in the operating environment can be as low as 5mg/m³

Truck loading

Port bulk loading

Mine yard

Carriage loading

Dry bulk material loading for open trucks and rail cars

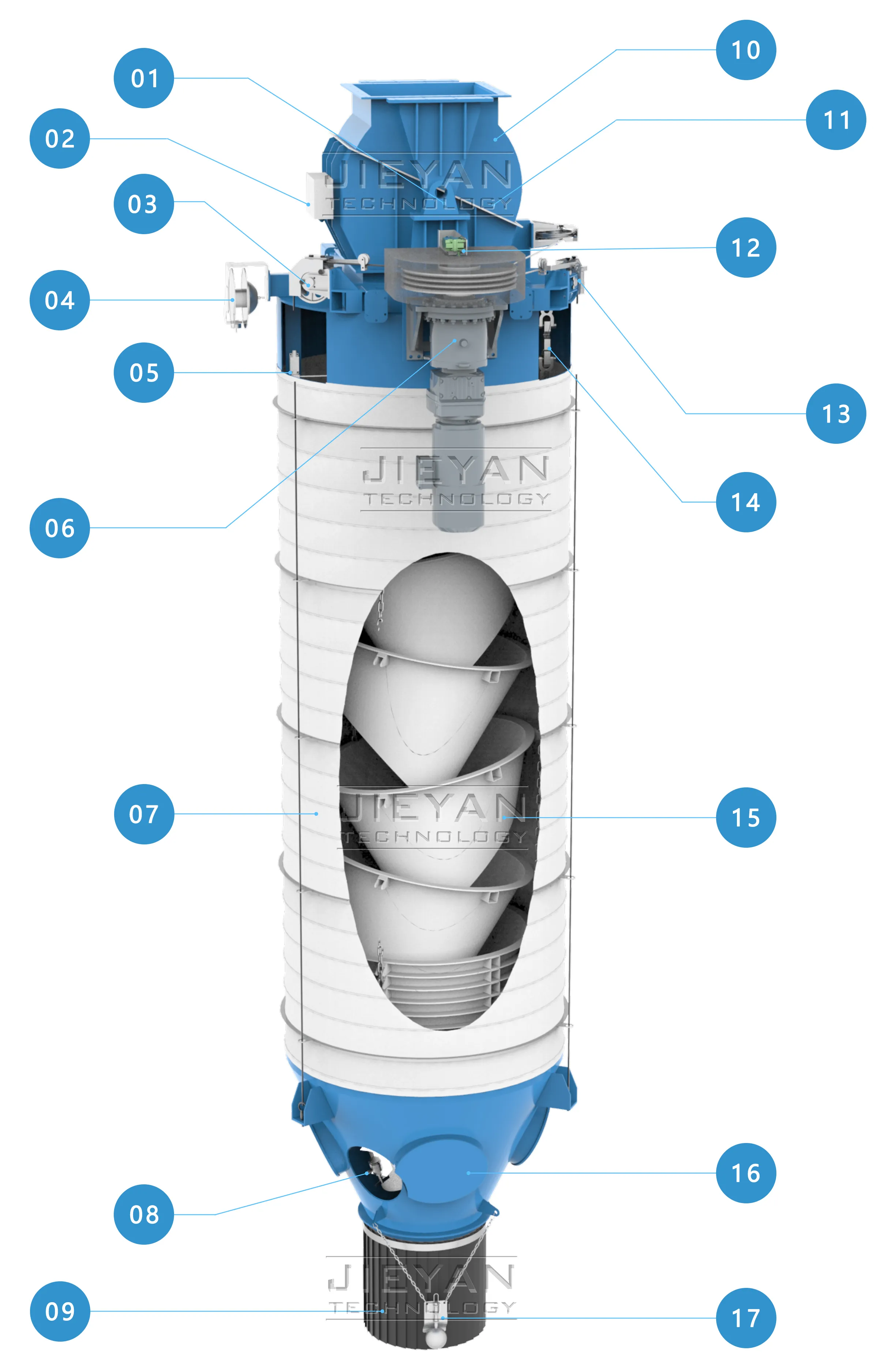

Structure and Principle

Its innovative geometric structure converts impact energy into frictional energy consumption on the flow-guiding surfaces, keeping the material falling speed within the safe threshold. This significantly reduces the breakage rate and pulverization rate, making it particularly suitable for the transportation of brittle materials such as coke and sulfur

Moreover, the series is equipped with exclusive laminar flow maintenance technology, which ensures that materials of different particle sizes remain uniformly mixed during transportation until reaching the final discharge point. This mechanism fundamentally guarantees the consistency of stockpile composition, effectively avoids quality fluctuations caused by material stratification, and reduces the additional cost of subsequent homogenization processes

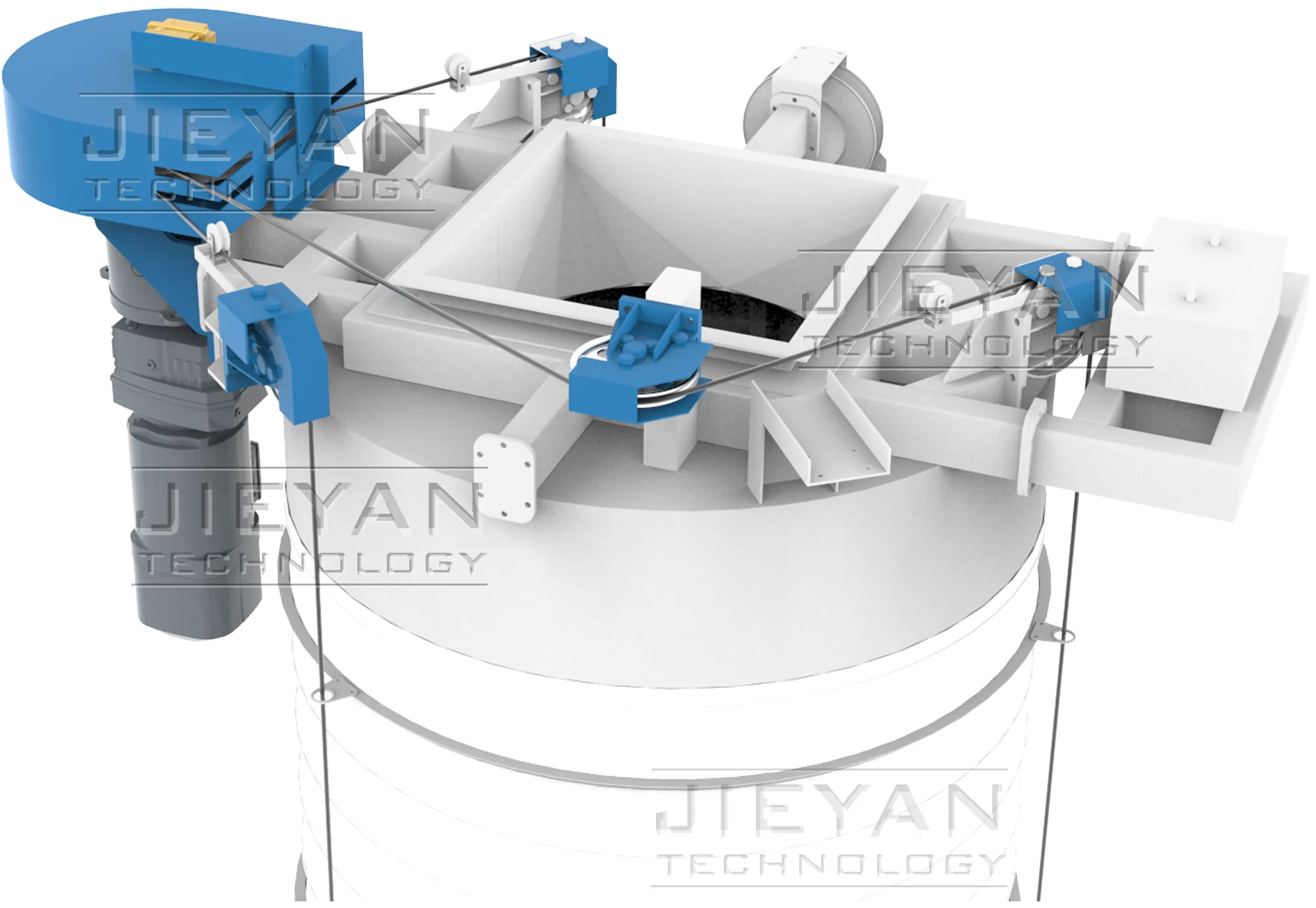

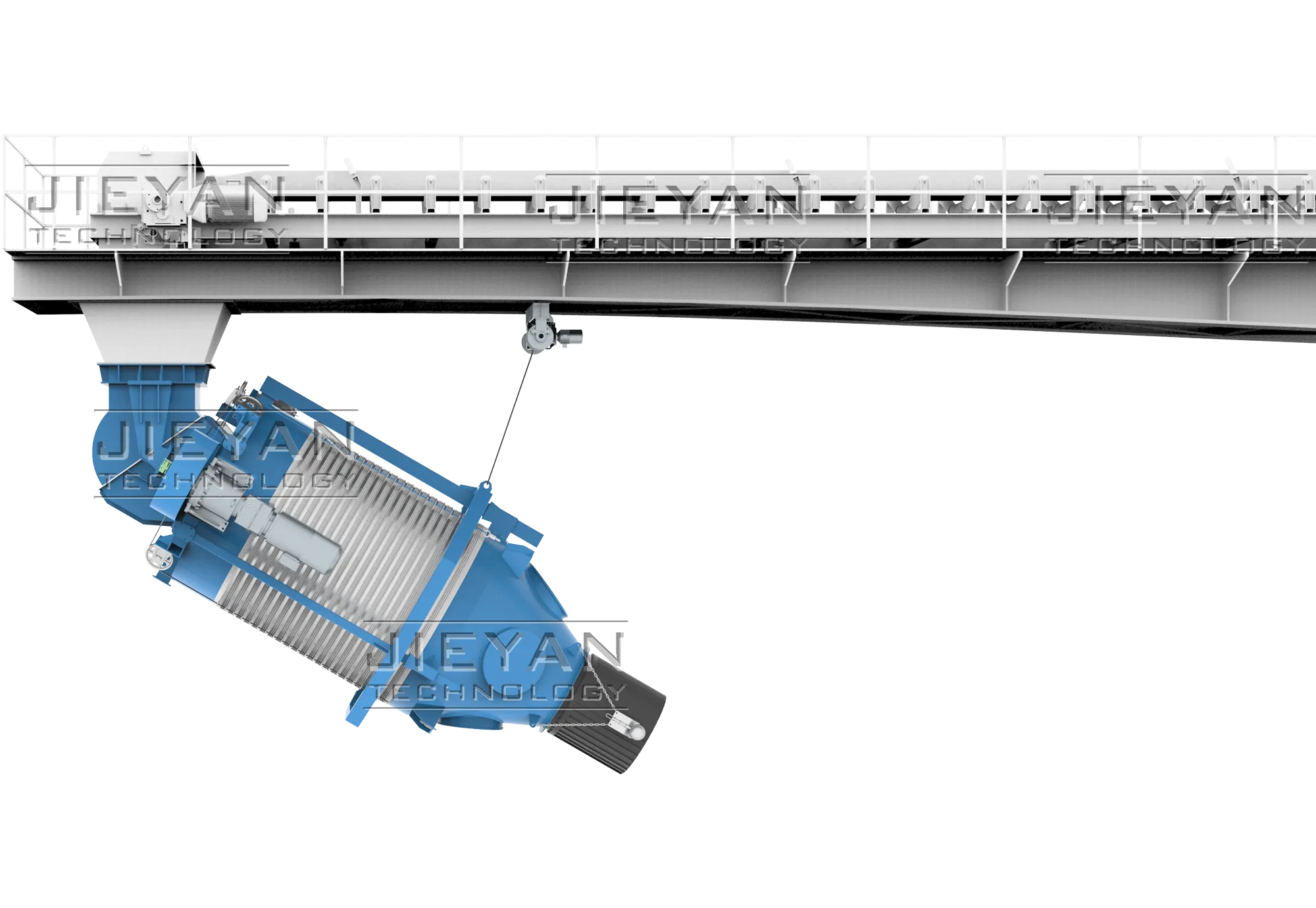

① Boom Assembly

② Junction Box

③ Guide Wheel Assembly

④ Hoisting Mechanism Assembly

⑤ Upper Limit Emergency Switch

⑥ Hoisting Mechanism Assembly

⑦ Dust-proof Drum

⑧ Level Switch

⑨ Dust-proof Skirt

⑩ Rotatable Material-Receiving Hopper Assembly

⑪ Sealing Felt

⑫ Rotary Limit Switch

⑬ Rope Slack Switch

⑭ Tension Sensor

⑮ Cascading Conical Drum

⑯ Hoisting Mechanism Assembly

⑰ Tilt Switch

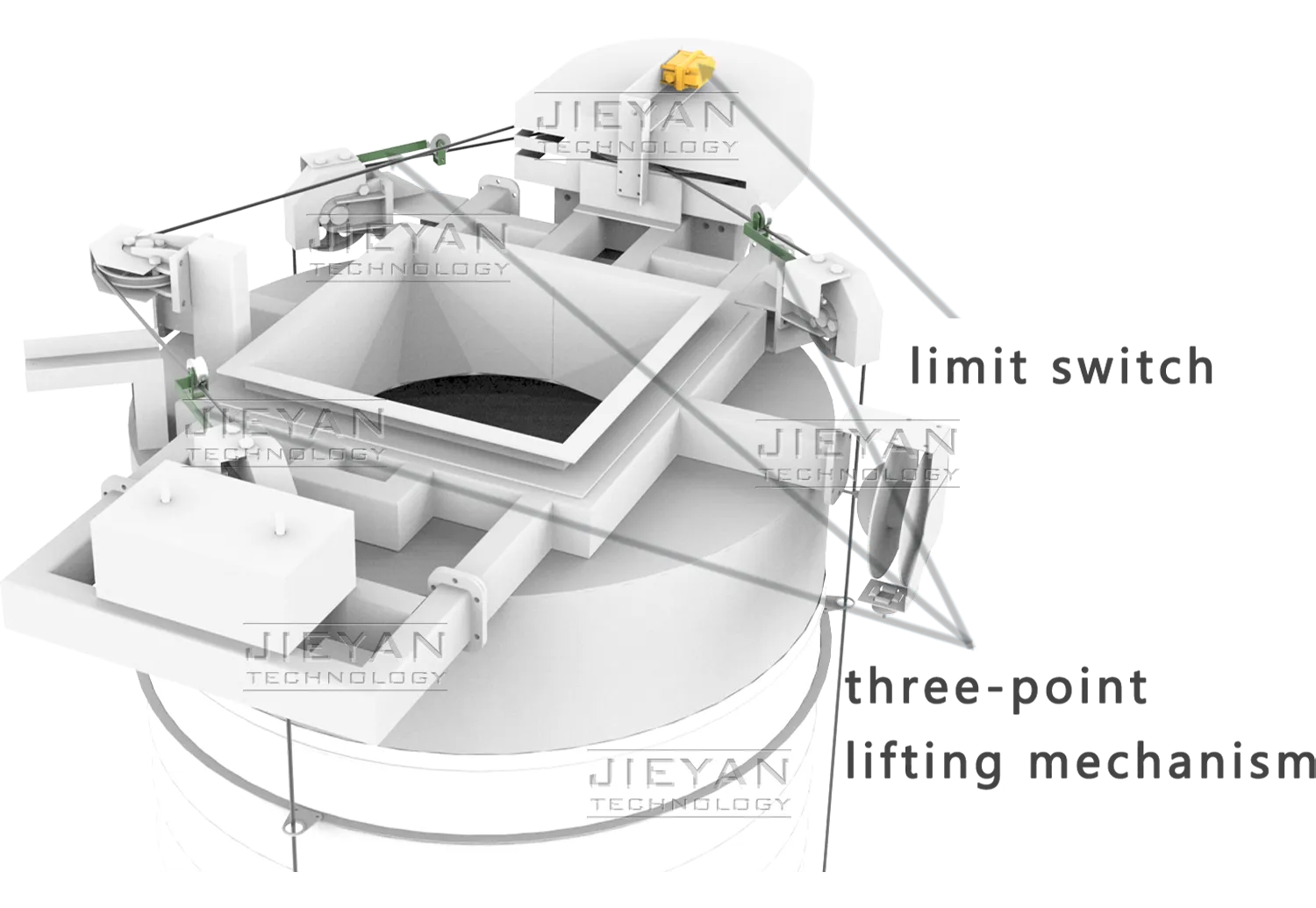

Technical Features

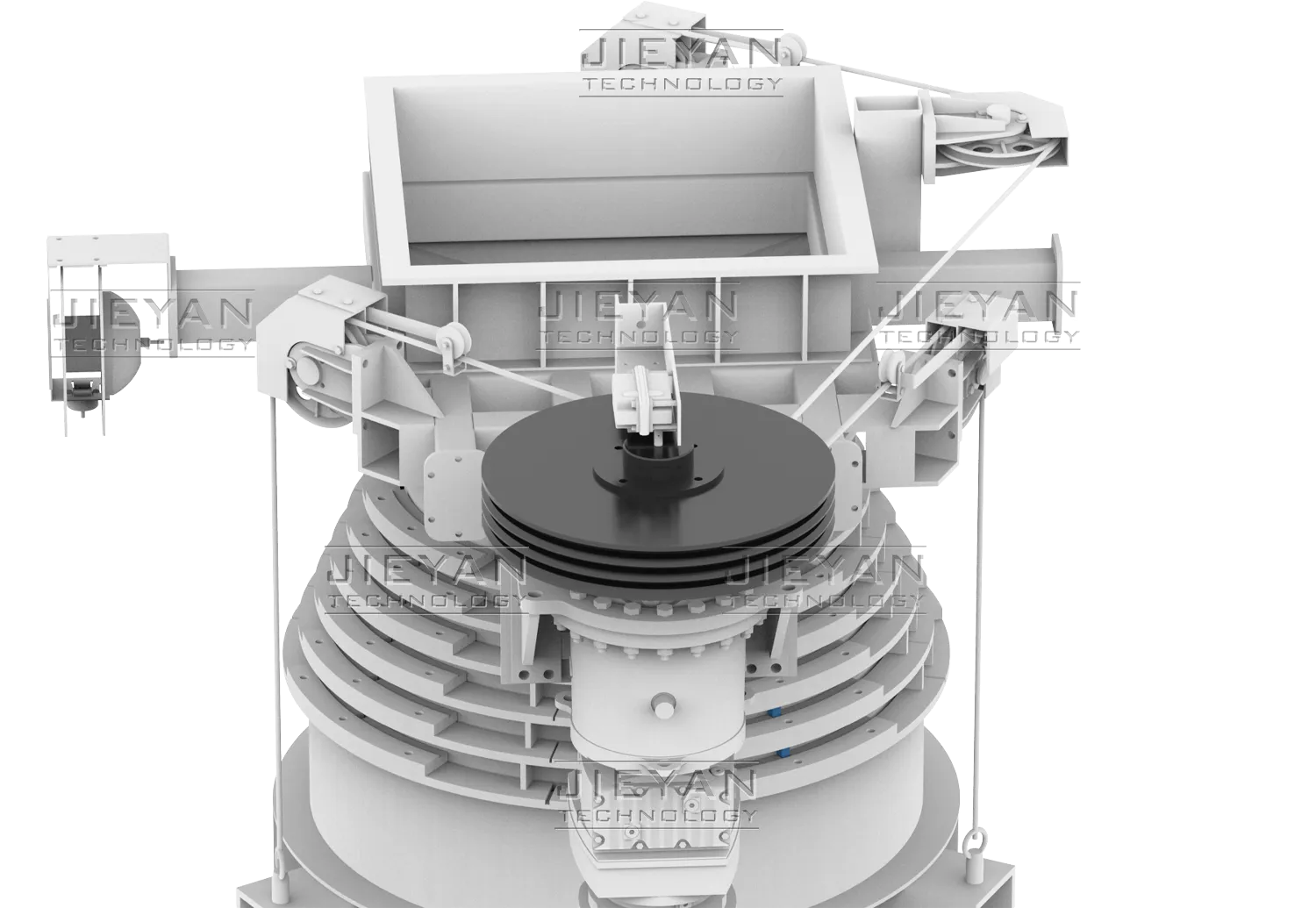

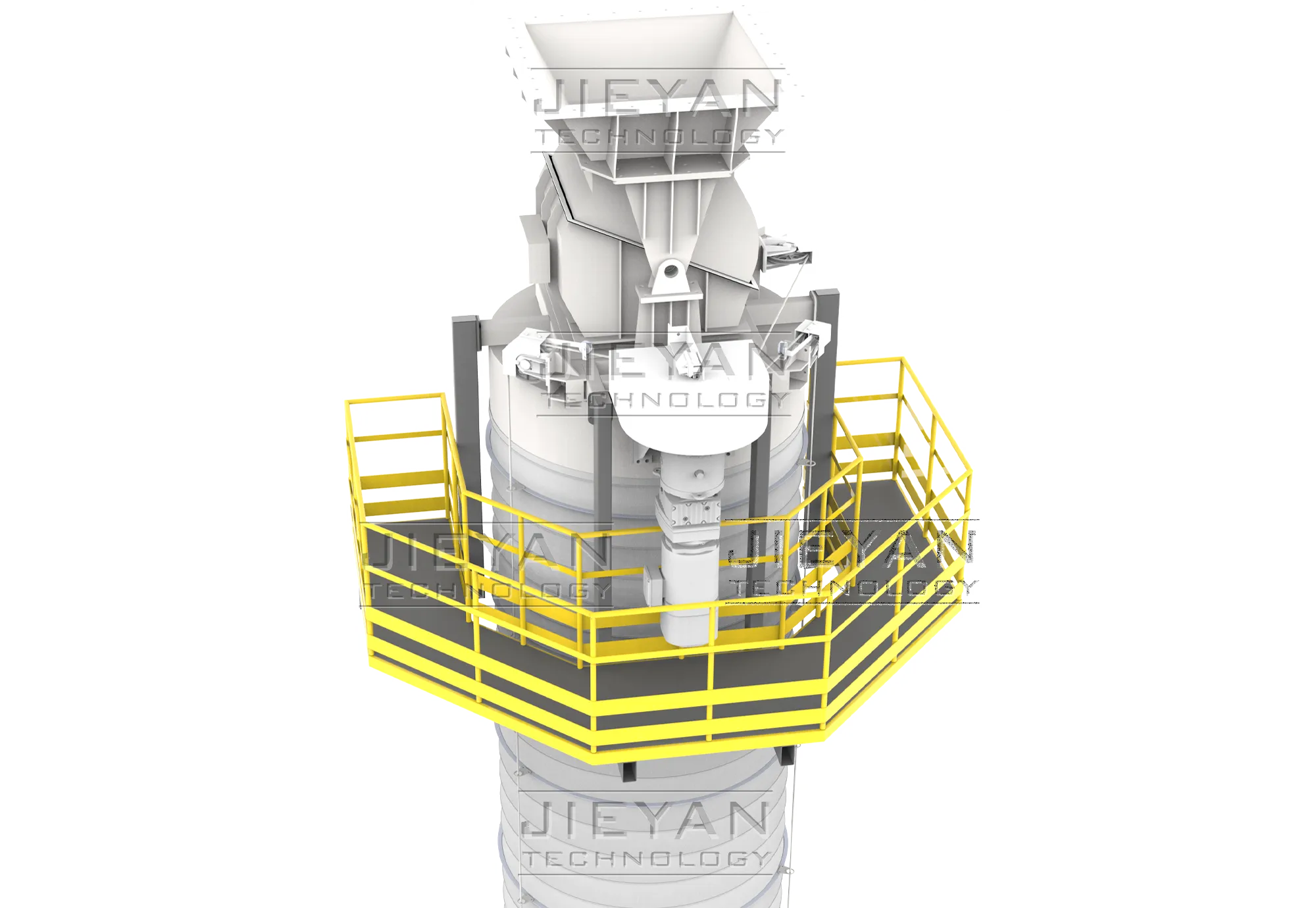

Space-Saving Integrated Design

The unified construction combines hoisting mechanism with spout body, creating a rigid and compact system that simplifies installation while maximizing structural integrity.

Triple-Rope Winch System

Three lifting points ensure exceptionally smooth operation, while the planetary gearbox delivers over 96% efficiency with high overload capacity - engineered for demanding heavy-duty applications.

Enhanced Core Components

Heat-treated and precision-finished shafts and winches feature smooth surfaces that minimize wire rope wear. All machined parts are zinc-plated for superior corrosion and abrasion resistance.

Configurable Wear Protection

Standard Q355B construction with optional NM abrasion-resistant steel, stainless steel variants, or specialized linings including ceramic, UPE and tungsten carbide hardfacing for extreme service conditions.

Intelligent Safety Systems

Programmable limit switches with backup settings and standard slack rope detection prevent overtravel and derailment, ensuring reliable protection.

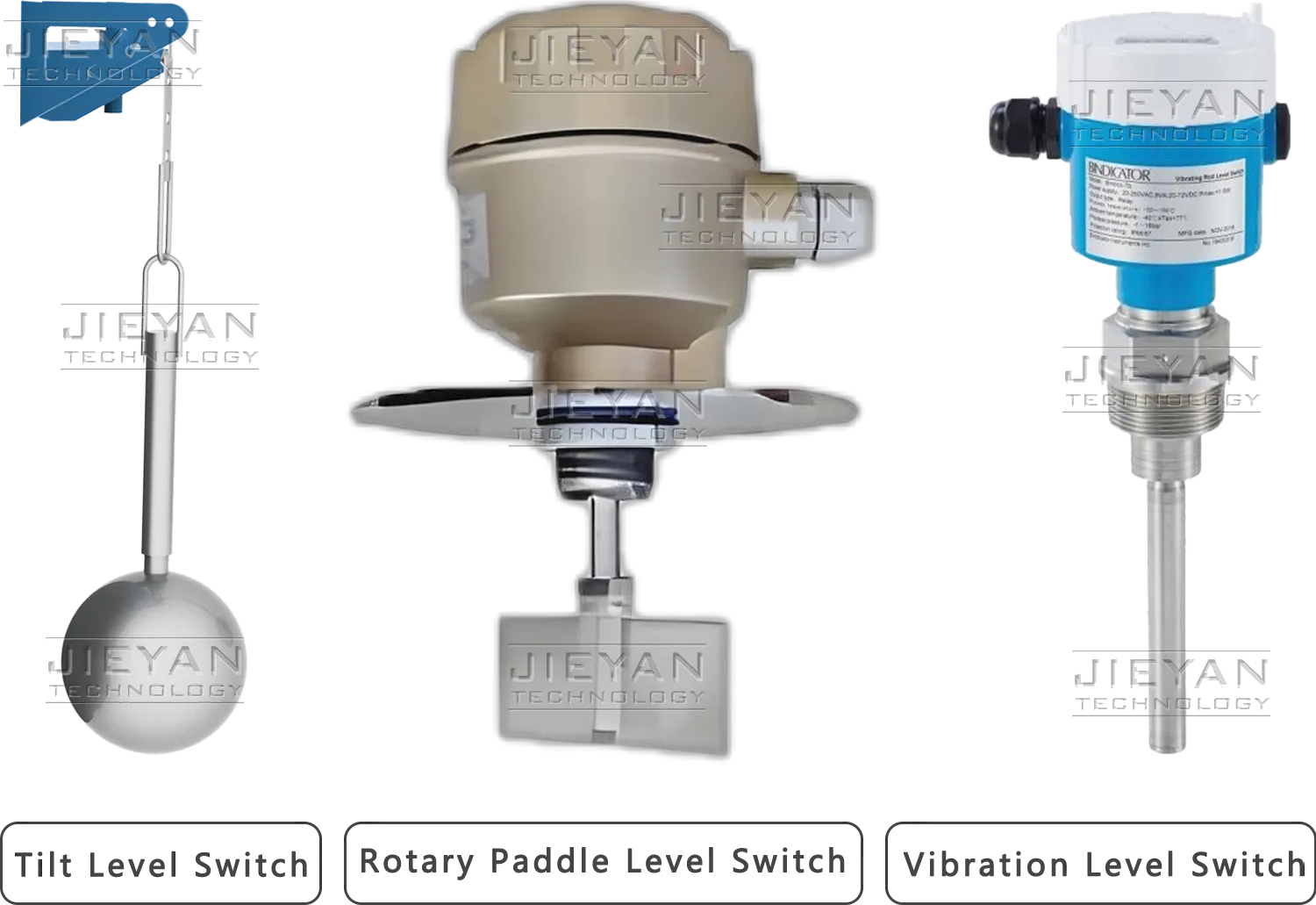

Flexible Level Monitoring

Choose from tilt, rotary paddle or vibration switches to achieve precise level detection across various materials and mounting configurations.

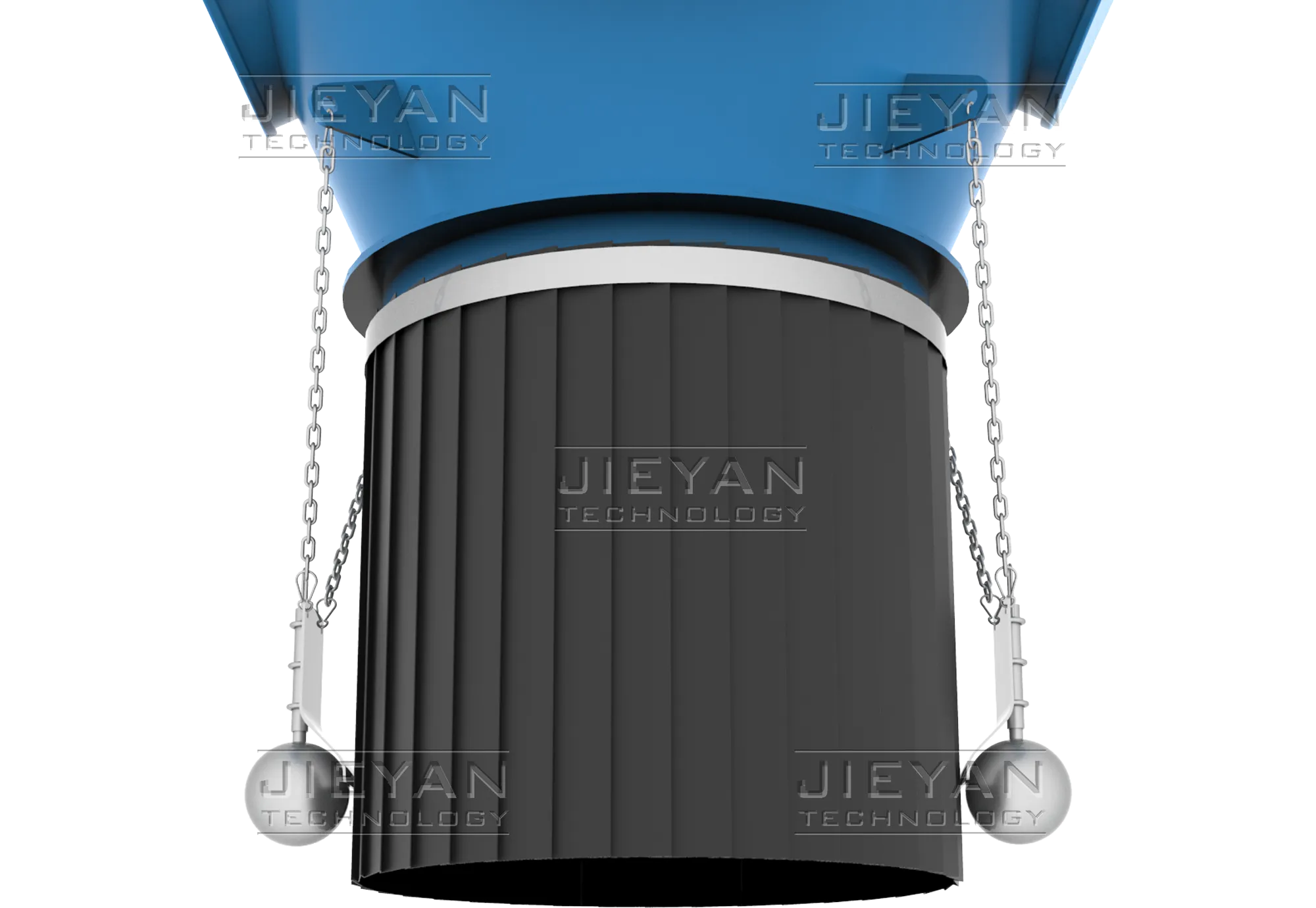

Double-Layer Dust Containment

Reinforced rubber skirt creates a secure seal with container outlets, effectively preventing dust emission to meet environmental standards.

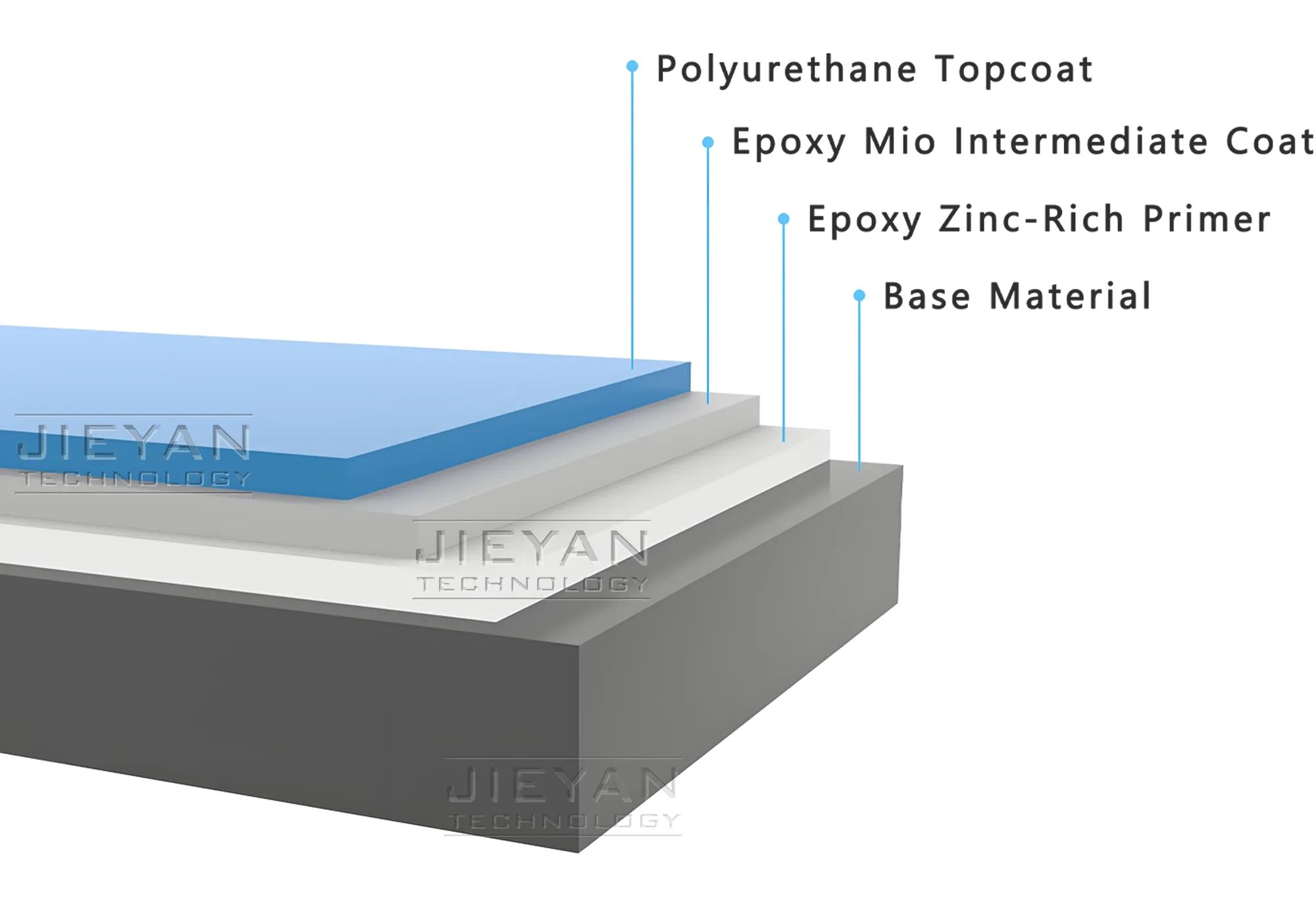

Professional Corrosion Protection

SA2.5 blasting preparation combined with a triple-layer coating system (zinc-rich epoxy, micaceous iron oxide, polyurethane) delivers ≥200μm of durable protection.

Advanced Control System

Featuring Schneider components with wireless remote and PLC+HMI interface, the system offers Ethernet connectivity for seamless plant integration.

Optional Accessories

Rotary Leveler

Maintenance Platform

Side-pull Folding Device

Related Cases

Related products

Contact Us

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219

Submit Successfully!

We have received your message and will contact you soon.