01 Improving loading efficiency:

Intelligent loading systems employ automation and smart technologies to achieve rapid and precise loading of cement, significantly enhancing loading efficiency while reducing the complexities and errors associated with manual operations.

02 Ensuring Measurement Accuracy:

The system integrates high-precision load cells and measurement devices, enabling accurate weight and volume measurements. This effectively prevents inaccuracies caused by human factors, ensuring both the quality and quantity of the cement.

03 Optimizing Resource Utilization:

Through the intelligent loading system, enterprises can achieve precise batching based on actual needs, avoiding resource wastage or shortages, thereby realizing optimal resource allocation.

04 Enhanced Safety:

The intelligent loading system enables remote control and monitoring, reducing manual intervention and minimizing the risks workers face in harsh environments, thereby enhancing operational safety.

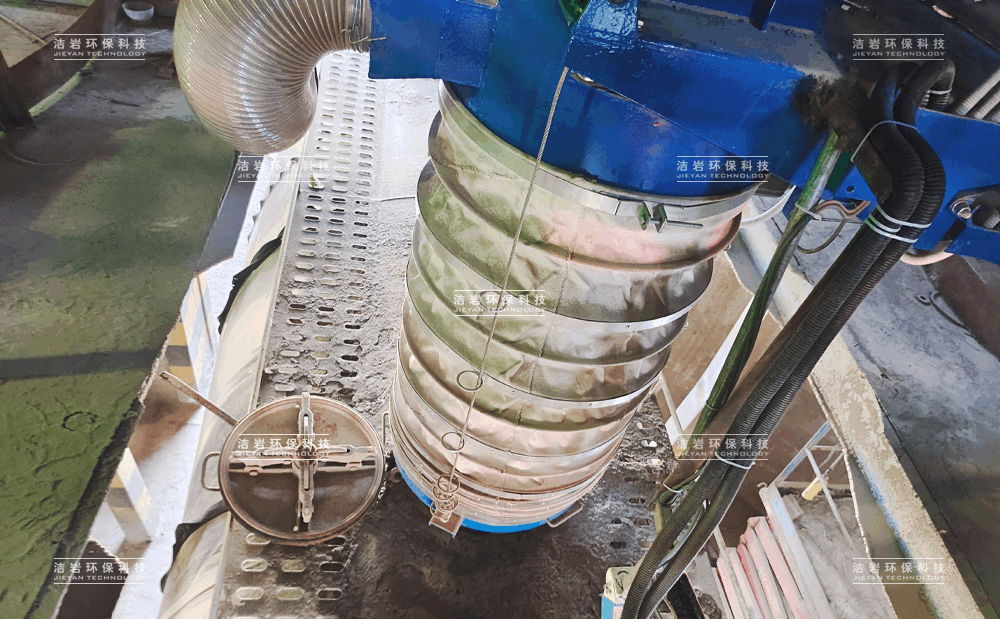

05 Enhancing Environmental Performance:

The system employs a closed loading method, effectively reducing the dispersion and emission of cement dust, mitigating environmental pollution, and enhancing the company's environmental performance.

Summary:

In summary, the application of the intelligent tanker loading system in bulk cement handling enhances efficiency, ensures measurement accuracy, optimizes resource allocation, improves safety, and boosts environmental performance. This supports enterprises in achieving modern, intelligent, and sustainable development.