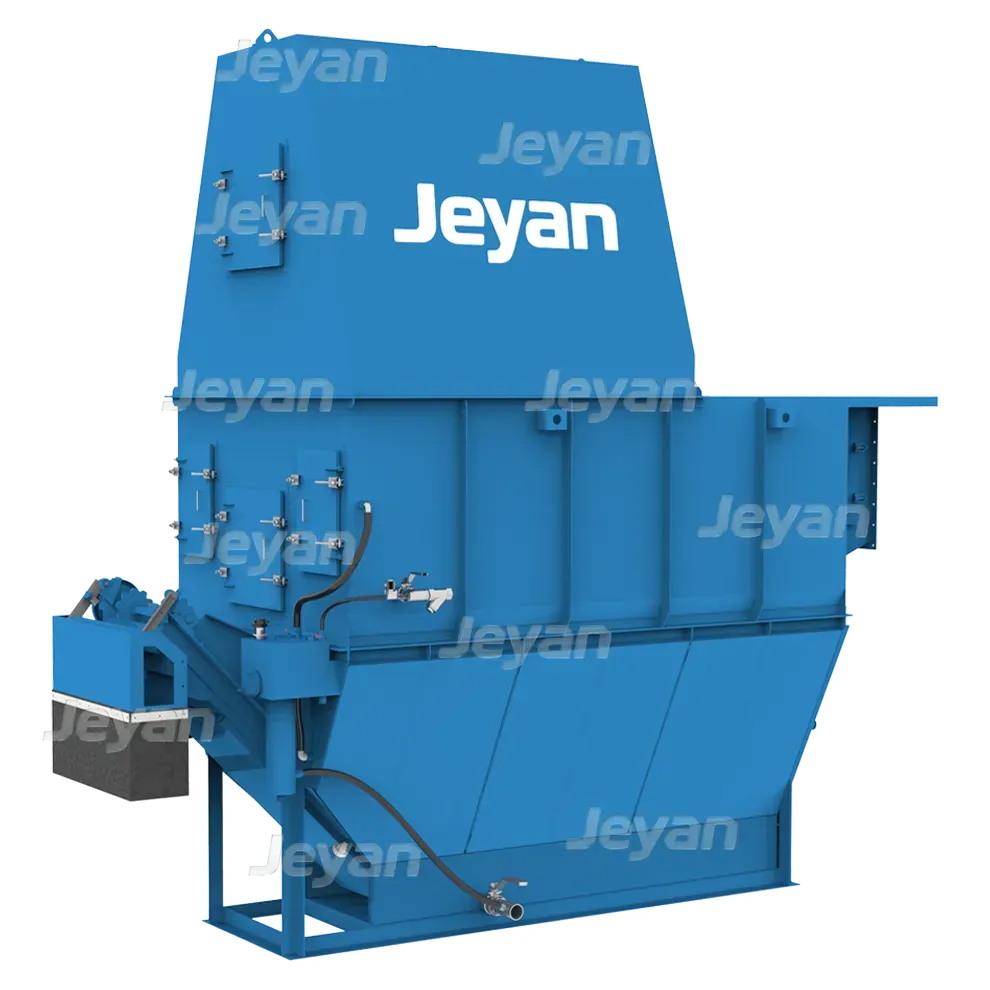

Wet Dust Collector for Sinter Mixer

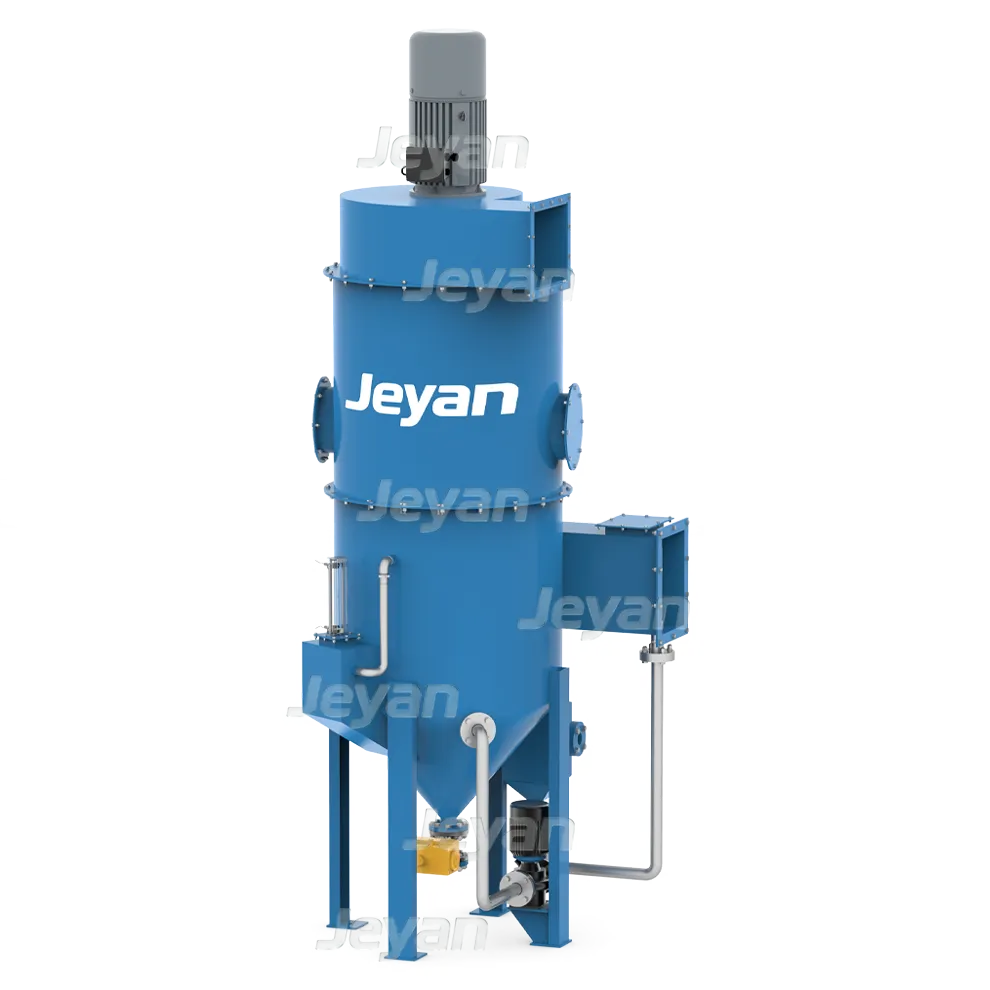

The No. 2 450-square-meter primary mixer at the sintering plant of Jiangsu Yonggang Group's ironmaking facility has been facing dust pollution issues, with significant dust spillage occurring at the mixer inlet, feed belt, and the drop point at the tail end of the secondary mixer belt. To address this, an MDC multi-stage high-efficiency wet dust collector system was implemented. This system ingeniously integrates technologies such as spray dust removal, Venturi dust removal, and cyclone dust removal to achieve multi-stage filtration and efficient capture of dust. When flue gas enters the dust collector, it first undergoes primary water spray treatment, where the solution absorbs and effectively removes particulate matter and soluble harmful components from the dust-laden gas. Subsequently, the gas passes through the Venturi rod layer for deep collision and mixing, allowing water droplets to further adsorb dust particles. After primary and secondary dust-water separation, the final gas-liquid separation is achieved in the cyclone dehydration unit, enabling cleaner production and compliance with ultra-low emission standards.

【Equipment Model】:MDC-10D

【Dust removal efficiency】:Above 99%

【Application Areas】:Sintering mixing, slag quenching pits, light metal polishing and grinding, biomass power generation

Related Products

Contact Us

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219

Submit Successfully!

We have received your message and will contact you soon.