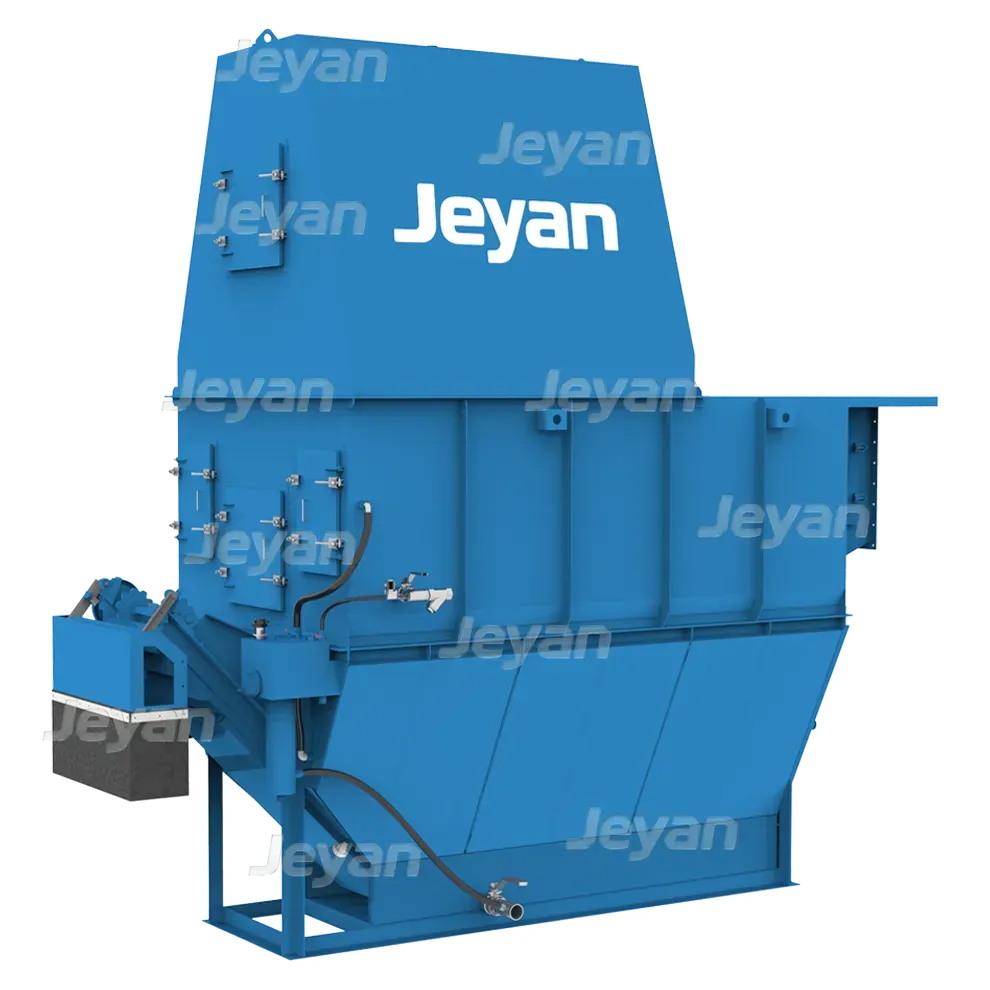

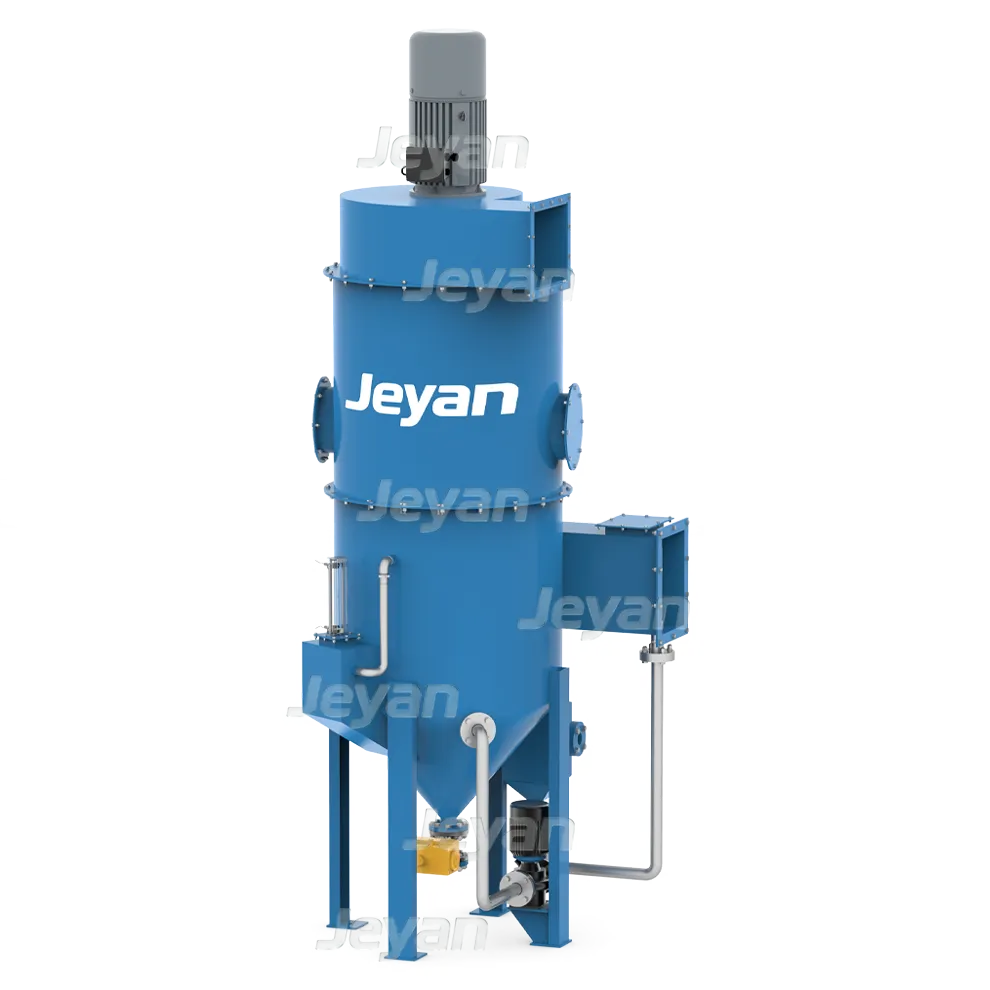

Wet Dust Collector for Sintering Machine Mixer

According to the national ultra-low emission concentration standards for environmental protection, Panzhihua Iron and Steel Group's Vanadium Titanium Ironmaking Plant has adopted a wet dust removal system designed, produced, and installed by Shanghai Jieyan Environmental Technology Co., Ltd. This system features high dust collection efficiency, low maintenance costs, and the recycling of dust removal water. It perfectly resolves the long-standing issue of non-compliant flue gas emissions during the sintering process. The newly installed wet dust removal system incorporates dust collection pipelines at the flue gas desulfurization system of each sintering machine and at the inlet and outlet of the primary mixer, effectively treating high-temperature flue gases and dust collected from emission points. This reduces fugitive emissions during the sintering batching process, lowers maintenance costs, and improves the working environment in the sintering area. After the implementation of this project, the dust concentration in the sintering batching area decreased from 50 mg/Nm³ before the upgrade to ≤10 mg/Nm³.

【Equipment Model】:HDC-48

【Dust removal efficiency】:Above 99%

【Application Areas】:Sintering mix, slag quenching pits, light metal polishing and grinding, biomass power generation.

Related Products

Contact Us

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219

Submit Successfully!

We have received your message and will contact you soon.