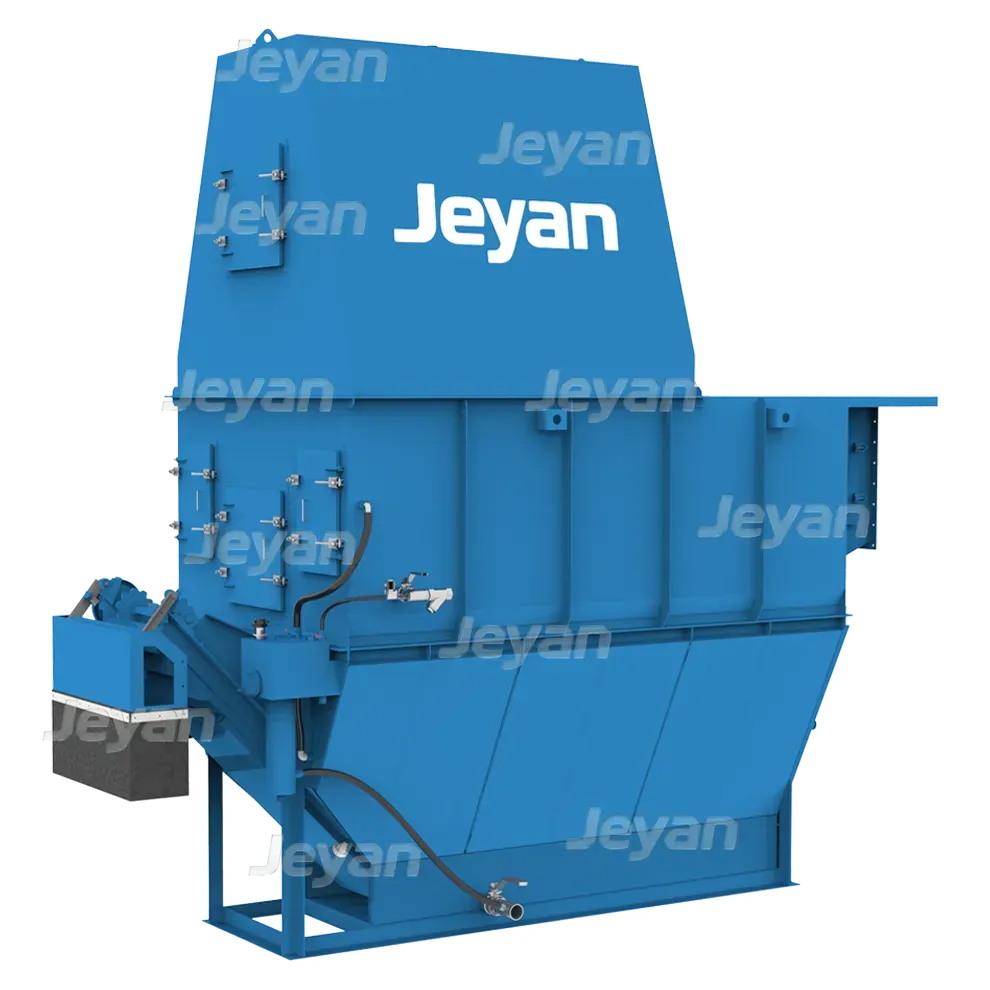

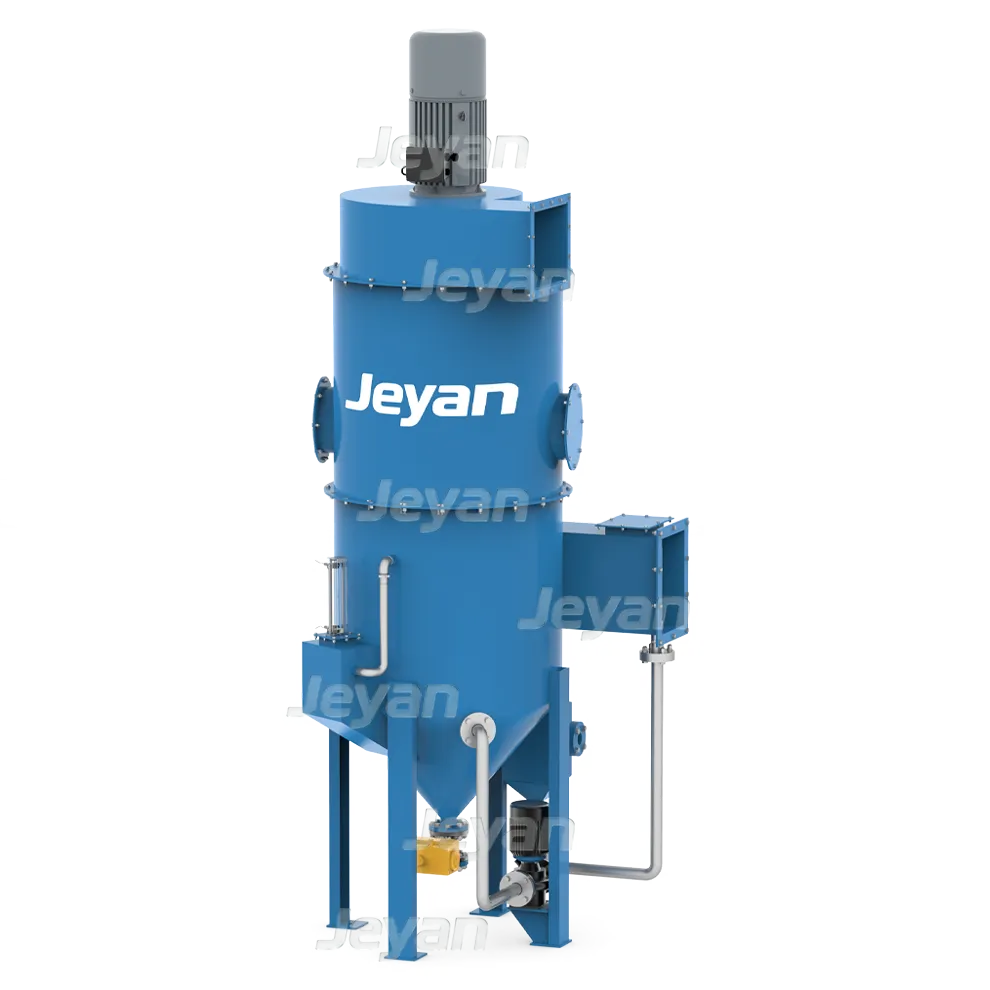

Wet dust collector for steel slag treatment

During the steel slag treatment process, a significant amount of steam-borne dust is generated during operations such as transportation, crushing, screening, rod milling, magnetic separation, and truck transfer. This severely impacts the plant environment and personnel health. Consequently, the dust concentration in the steel slag treatment process far exceeds the comprehensive emission standard requirement of 10mg/m³. To achieve ultra-low emissions, it is urgent to implement control measures.

According to the national Opinions on Promoting the Implementation of Ultra-Low Emissions in the Steel Industry, to meet the ultra-low emission requirements of Jiangsu Yonggang Group Co., Ltd., comply with national environmental regulations, and achieve cleaner production, it is necessary to further control the entire steel slag treatment process. This includes installing wet dust collectors and dry mist suppression equipment in key areas such as the crushing workshop, No. 1 screening workshop, No. 2 screening workshop, distribution silo area, three rod mills, No. 5 transfer station, No. 6 transfer station, No. 3 screening workshop, and the final magnetic separation area, thereby meeting the requirements for ultra-low emissions and cleaner production.

【Equipment Model】:HDC-48D

【Dust removal efficiency】:Above 99%

【Application Areas】:High-temperature, high-humidity, highly viscous, flammable and explosive dust. Applications include sinter mixing, slag quenching pits, light metal polishing and grinding, and biomass power generation.

Related Products

Contact Us

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219

Submit Successfully!

We have received your message and will contact you soon.