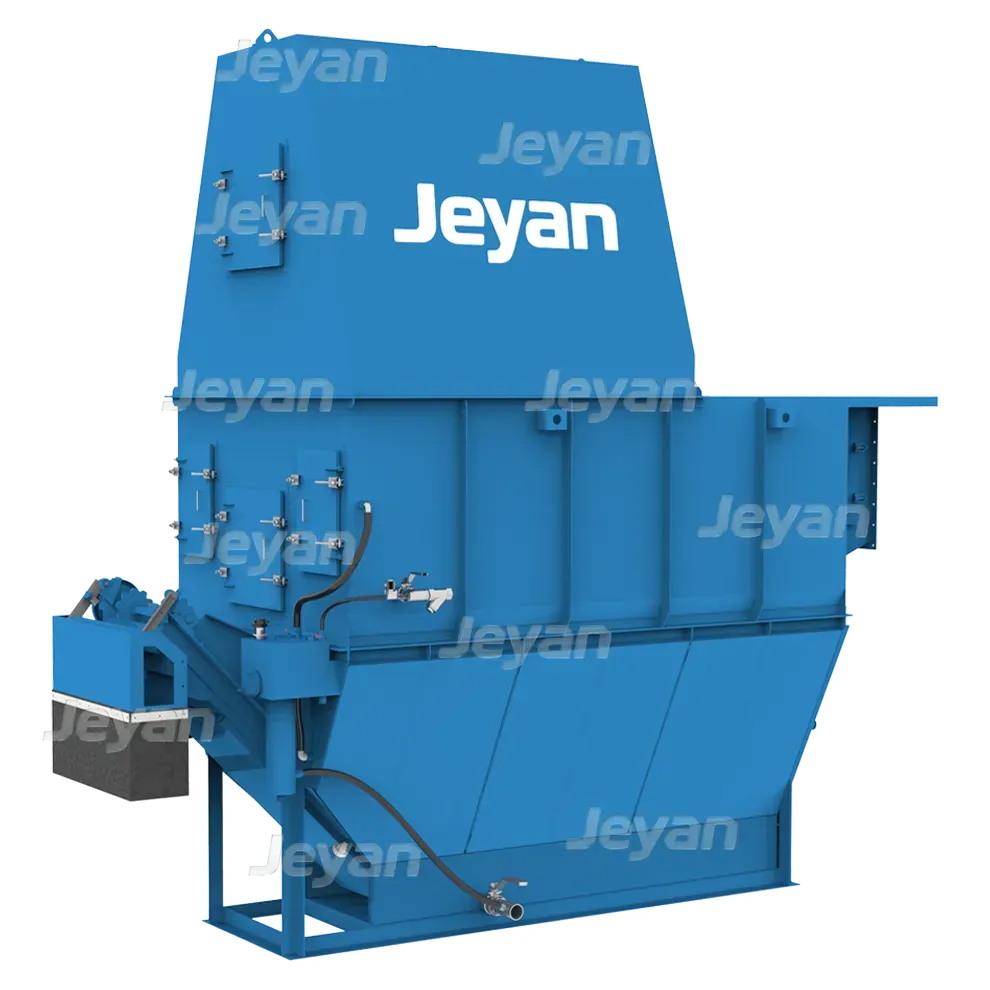

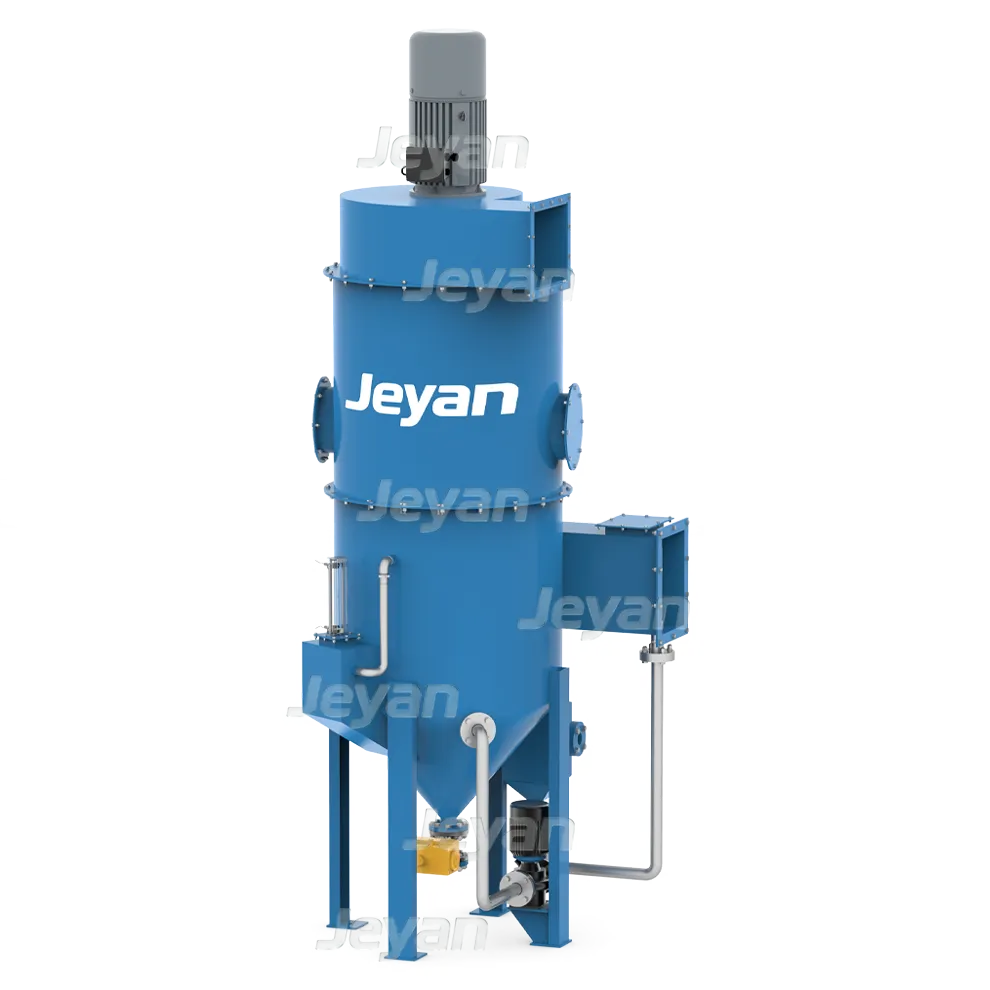

High-Efficiency Wet Dust Collection for Mixer

During the mixing and pelletizing process of sinter mix in the secondary mixer of the 2×500㎡ sintering machines at Shangang Group Rizhao Company, a significant amount of steam-borne dust is generated. This dust contains substantial amounts of raw lime, return fines, iron ore fines, and other materials, leading to visible steam and dust emissions at the mixer's inlet and outlet. This not only deteriorates the plant environment but also results in material loss and equipment corrosion. To meet Rizhao Company's ultra-low emission targets, comply with national environmental requirements, and achieve cleaner production, it is necessary to further control the dust emissions from the secondary sinter mixer. Installing additional dust collection points at the mixer's inlet and outlet is essential to satisfy both ultra-low emission standards and cleaner production objectives.

【Equipment Model】:HDC-48D

【Dust removal efficiency】:Above 99%

【Application Areas】:High-temperature, high-humidity, high-viscosity, flammable and explosive dust. Applications include sinter mixing, slag quenching pits, light metal polishing and grinding, and biomass power generation.

Related Products

Contact Us

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219

Submit Successfully!

We have received your message and will contact you soon.