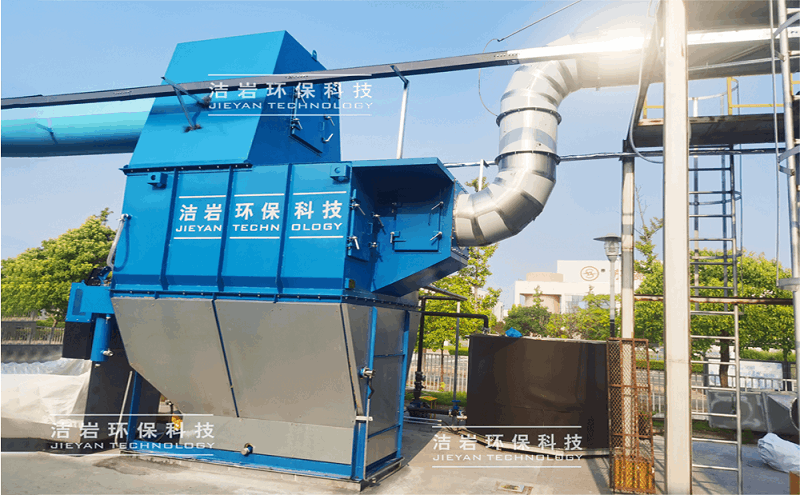

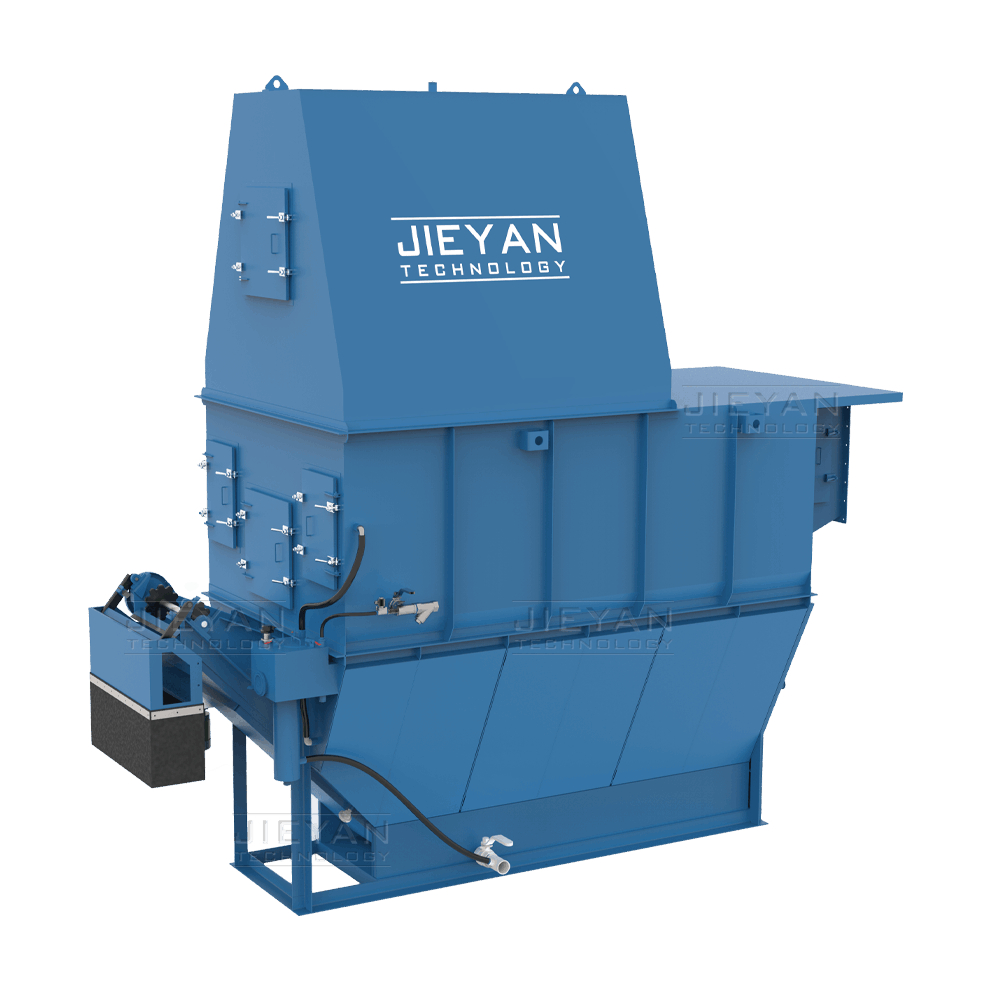

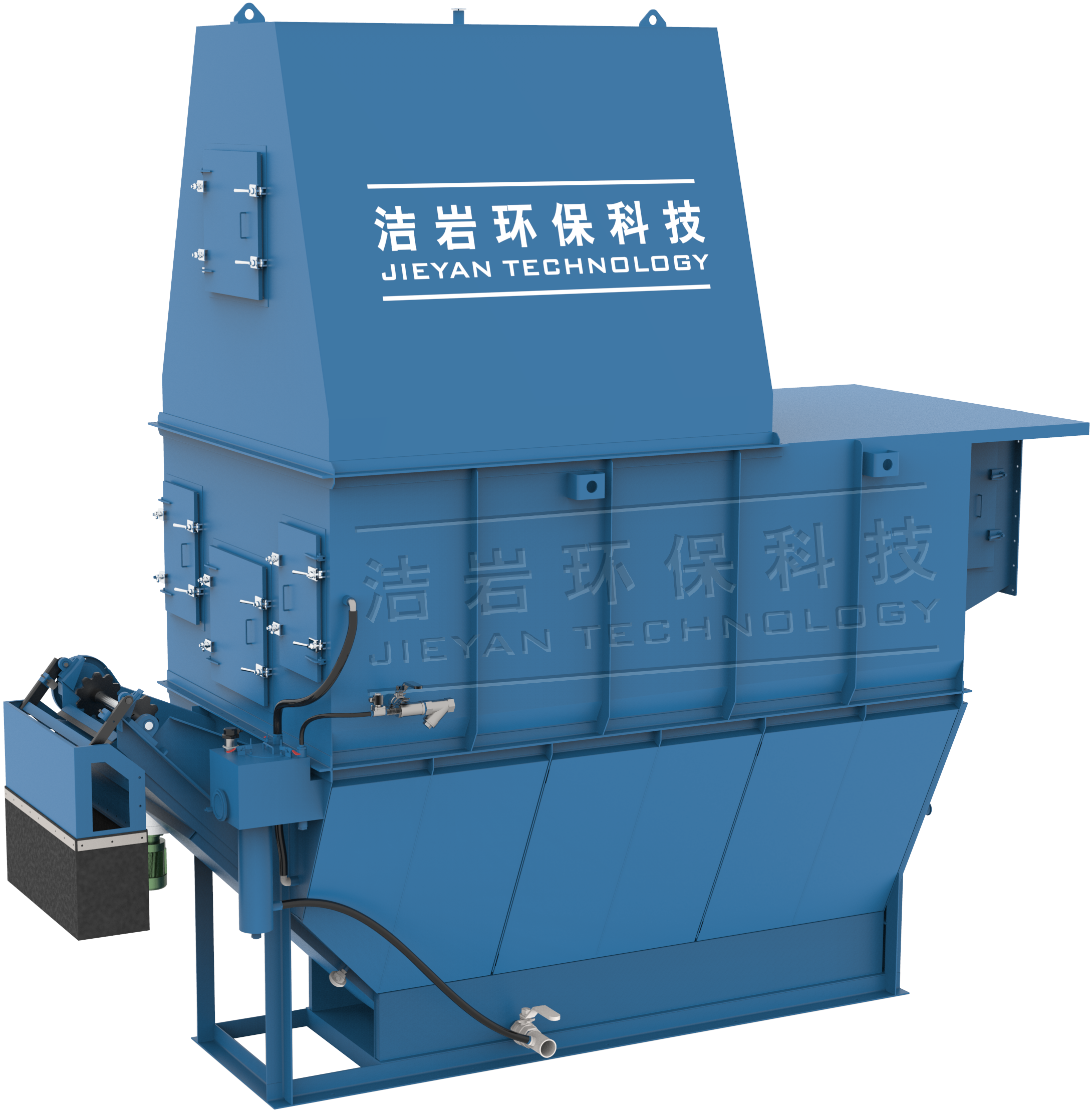

HDC series Wet dust collectors combine high efficiency, low maintenance costs, simplicity, flexibility and low water usage to maximize performance. HDC series Wet dust collectors are designed for a wide range of operating conditions with minimal servicing requirements. Collection efficiencies, including the most challenging particle sizes, are equal to or better than any wet dust collector with comparable energy consumption.

Polishing dust

Viscous dust

Steam and oil fog

Flammable and explosive dust

Fiber / Fluff / Fabric dust

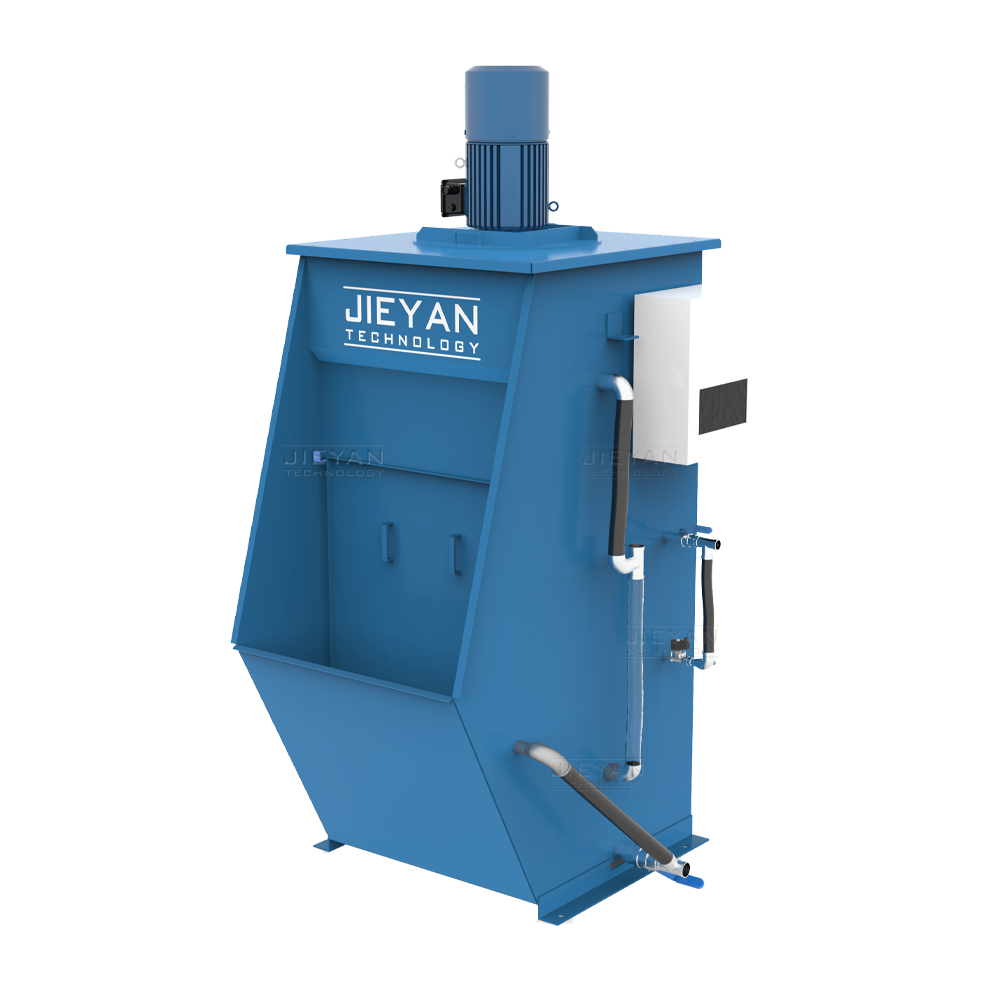

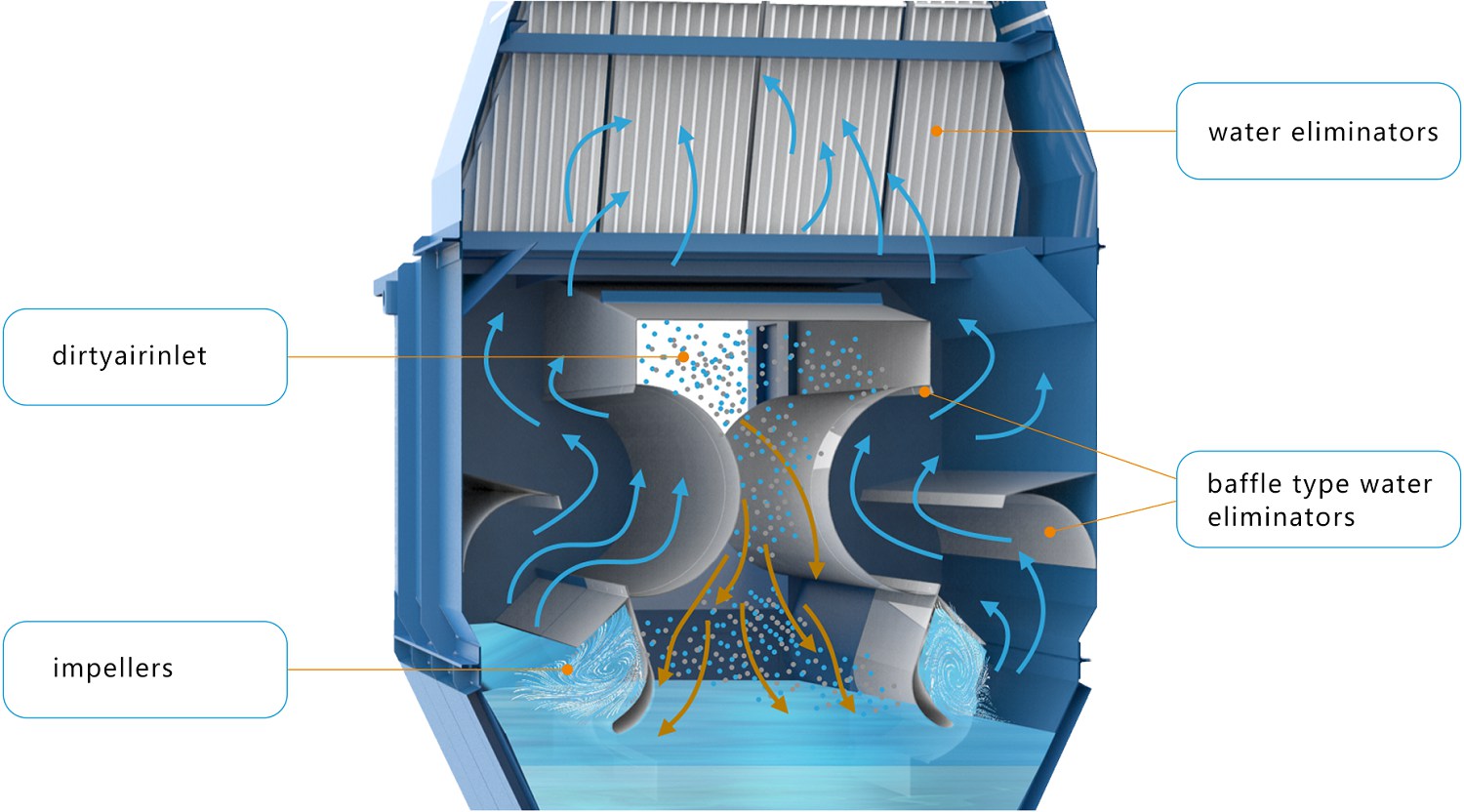

Working principle

✦ The HDC air purifier operates on a dual-action principle,combining centrifugal force with the thorough amalgamation of water and air laden with particulates.The purification process begins when the air,carrying dust,encounters a water curtain generated by the passage of air through a partly submerged static impeller.As the air rushes through the impeller at high speeds,it carries along a turbulent laver of water,enhancing the interaction between the water and the dust particles.

✦ To further augment this interaction, additional water is strategically introduced into the narrowest part of the impeller's aperture via a specifically engineered slot located at the base. This upward flow of water through the slot significantly boosts the contact between dust and water, thereby elevating the efficiency of particle collection.

✦ The centrifugal force resulting from the abrupt shifts in the direction of airflow propels the dust particles into the water film,where they are securely ensnared. The purified air, now laden with water droplets, undergoes a final stage of treatment where the water is extracted by either a set of wide-spacing chevron eliminators designed for smaller models or a trio of curved de-entrainment baffles tailored for larger units.

✦ The system utilizes a continuous circulation of water within the reservoir, eliminating the need for external pumps or nozzles to create the water curtain. Freshwater is periodically replenished through a dedicated makeup water connection to counteract any losses due to evaporation or the removal of collected dust from the system. This innovative design ensures an efficient and sustainable method of air purification without the reliance on conventional mechanical components.

Sludge Disposal Methods

Arrangement B – Manual Sludge Removal

Arrangement B, is designed for reduced height and low initial cost. Collected materials will be removed manually.

Arrangement C – Automatic Sludge Removal

Arrangement C, is designed to reduce manual removal of collected material. Collected materials will be removed by automatic drag-type sludge removal.

Arrangement D

Arrangement D, is designed to sluice collected material through the hopper into a process or disposal point. Sluicing may be continuous or intermittent.

Tech Specs

| Model | Processing air volume(m3/h) | Power(kw) | Pressure loss(Pa) | Purification efficiency(%) | noise(dB) |

| HDC-1.5 | 2520-3034 | 4-5.5 | 1643-1892 | 99 | 75 |

| HDC-2.5 | 4200-5040 | 5.5-7.5 | 1494-1743 | 99 | 75 |

| HDC-4 | 6720-8064 | 7.5-11 | 1494-1743 | 99 | 80 |

| HDC-6 | 10080-12096 | 11-18.5 | 1494-1743 | 99 | 80 |

| HDC-8 | 13440-16128 | 18.5-22 | 1494-1743 | 99 | 80 |

| HDC-12 | 20160-24196 | 22-37 | 1494-1743 | 99 | 90 |

| HDC-16 | 26880-32256 | 37-45 | 1494-1743 | 99 | 90 |

| HDC-20 | 33600-40320 | 45-55 | 1494-1743 | 99 | 90 |

| HDC-24 | 40320-48384 | 45-55 | 1494-1743 | 99 | 90 |

| HDC-28 | 47040-56448 | 55-75 | 1494-1743 | 99 | 90 |

| HDC-32 | 53760-64512 | 55-75 | 1494-1743 | 99 | 90 |

| HDC-36 | 60480-72576 | 90-110 | 1494-1743 | 99 | 90 |

| HDC-40 | 67200-80640 | 90-110 | 1494-1743 | 99 | 90 |

| HDC-44 | 73920-88704 | 110-132 | 1494-1743 | 99 | 90 |

| HDC-48 | 80640-96768 | 132-160 | 1494-1743 | 99 | 90 |

Related products

Contact Us

Welcome to follow Jieyan

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219